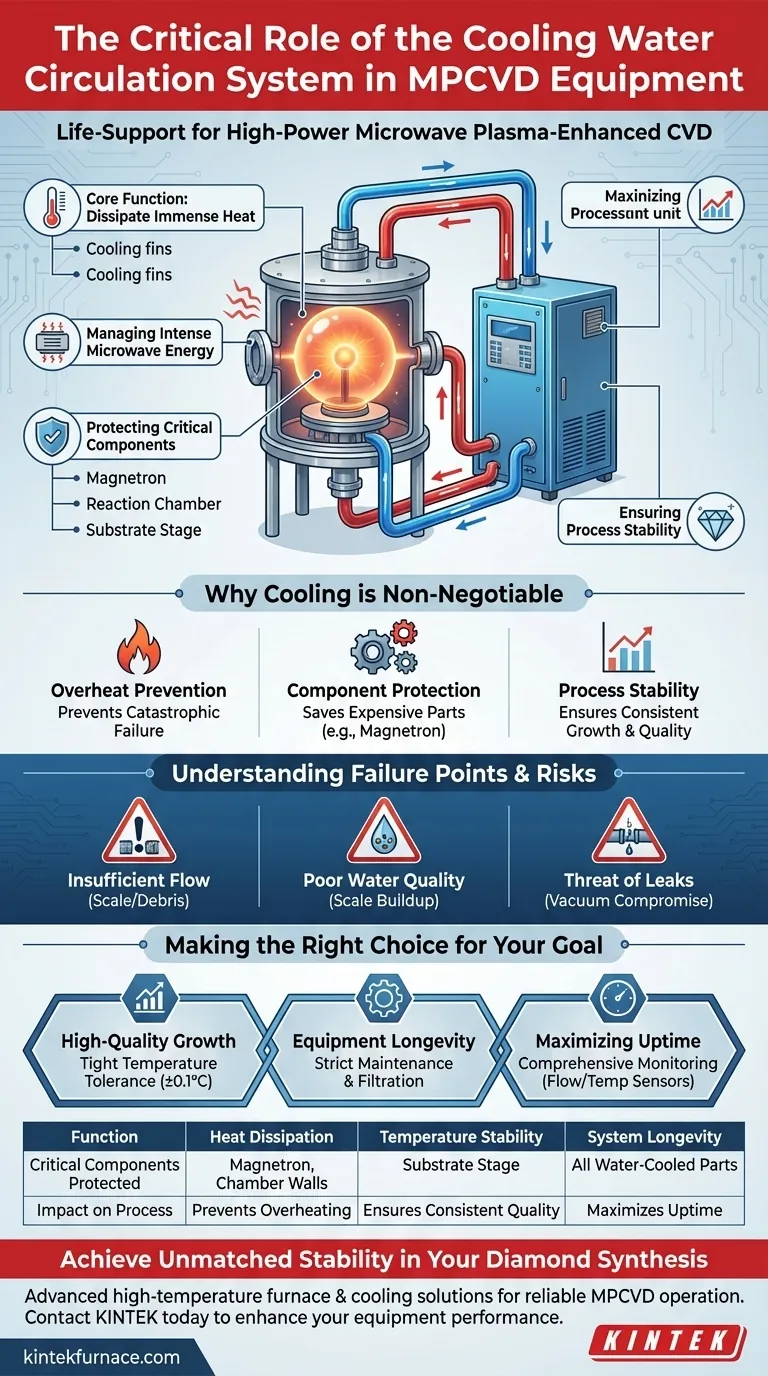

At its core, the cooling water circulation system is the life-support for Microwave Plasma-Enhanced Chemical Vapor Deposition (MPCVD) equipment. Its primary role is to manage and dissipate the immense heat generated by high-power microwaves, ensuring the entire system can operate safely, stably, and continuously for long-term material growth processes.

The cooling system is not a peripheral utility; it is a critical subsystem that directly enables the high-energy plasma environment required for diamond synthesis. Without it, the equipment would rapidly overheat, leading to catastrophic component failure and complete process instability.

Why Cooling is Non-Negotiable in MPCVD

The MPCVD process relies on creating and sustaining a ball of extremely hot plasma, often exceeding several thousand degrees Celsius. This intense energy is the engine for synthesis, but it also poses a significant thermal threat to the equipment itself.

Managing Intense Microwave Energy

The heart of an MPCVD system is the magnetron, which generates kilowatts of microwave power. This energy excites gases into a plasma state but also heats every component it interacts with, from the microwave guides to the reaction chamber walls.

The cooling system's first job is to actively remove this heat, preventing a runaway thermal cascade that would destroy the equipment.

Protecting Critical and Expensive Components

Several key parts of the MPCVD system are directly reliant on active cooling to survive.

- The Magnetron: The microwave generator itself produces significant waste heat and must be cooled to prevent it from burning out.

- The Reaction Chamber: The walls of the vacuum chamber absorb heat from the plasma. Cooling prevents them from warping or melting, which would cause a loss of vacuum and catastrophic failure.

- The Substrate Stage: While the substrate needs to be hot, its temperature must be precisely controlled. The cooling system provides the "cold side" of this thermal regulation, allowing heaters to maintain a stable, optimal temperature for high-quality growth.

Ensuring Process Stability and Repeatability

Successful diamond growth depends on maintaining a perfectly stable set of conditions for hours or even weeks.

Temperature fluctuations in the chamber walls or other components would alter the plasma's density, shape, and chemistry. This instability leads directly to inconsistent growth rates, defects in the crystal structure, and poor-quality results. A stable cooling system ensures a stable thermal environment, which is a prerequisite for a stable process.

Understanding the Failure Points

Because it is so critical, the failure of the cooling system is one of the most significant risks in MPCVD operation. Understanding its vulnerabilities is key to preventing downtime.

The Risk of Insufficient Flow

Any clog or restriction in the water lines can starve a component of coolant. This can be caused by mineral deposits (scale) or debris.

Modern systems incorporate digital flow sensors that will trigger an automatic shutdown if the flow rate to a critical component drops, protecting the equipment from damage.

The Problem of Poor Water Quality

Using standard tap water is a common and costly mistake. Dissolved minerals will precipitate out as the water heats up, forming an insulating layer of scale inside the cooling channels.

This scale dramatically reduces heat transfer efficiency, leading to component overheating even with normal water flow. It also causes clogs. For this reason, most systems use a closed loop of purified, deionized water for internal components.

The Threat of Leaks

Any leak, especially within the vacuum chamber, is a critical failure. Water entering the high-vacuum environment will instantly compromise the process and can damage sensitive components.

Regular inspection of all water line connections and seals is a fundamental part of routine MPCVD maintenance.

Making the Right Choice for Your Goal

Your approach to the cooling system should be dictated by your primary operational objective.

- If your primary focus is high-quality material growth: Ensure your chiller can hold the water temperature to within a very tight tolerance (e.g., ±0.1°C), as this thermal stability translates directly to process stability.

- If your primary focus is equipment longevity and safety: Implement a strict maintenance schedule for checking water quality, inspecting for leaks, and cleaning filters to prevent scale buildup and clogs.

- If your primary focus is maximizing uptime: Invest in a system with comprehensive monitoring, including flow and temperature sensors for all critical loops, to catch potential problems before they cause an emergency shutdown.

Ultimately, treating the cooling system as a precision instrument, integral to the synthesis process itself, is the key to achieving reliable and successful MPCVD operation.

Summary Table:

| Function | Critical Components Protected | Impact on Process |

|---|---|---|

| Heat Dissipation | Magnetron, Chamber Walls | Prevents overheating and catastrophic failure |

| Temperature Stability | Substrate Stage | Ensures consistent growth rates and crystal quality |

| System Longevity | All water-cooled parts | Maximizes equipment uptime and lifespan |

Achieve Unmatched Stability in Your Diamond Synthesis

Your MPCVD process is only as reliable as its cooling system. At KINTEK, we understand that precise thermal management is the foundation of high-quality material growth. Our advanced high-temperature furnace solutions, backed by exceptional R&D and deep customization capabilities, are designed to meet the exacting demands of your laboratory.

Whether you require a robust cooling system for a Tube Furnace, a Vacuum & Atmosphere Furnace, or a complete CVD/PECVD system, we can tailor the solution to your unique experimental requirements. Don't let thermal instability compromise your results.

Contact our experts today to discuss how we can enhance the reliability and performance of your MPCVD equipment.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What are some challenges associated with MPCVD? Overcome High Costs and Complexity for Diamond Synthesis