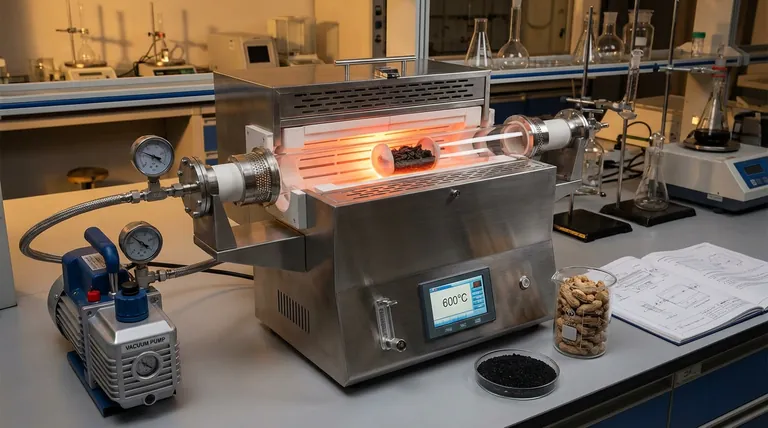

The primary role of the laboratory tube furnace is to act as a precise thermal reactor for isothermal pyrolysis. In the specific context of peanut shell biochar (KBC) preparation, this device maintains a vacuum-protected environment at 600 °C. This controlled setting allows for the removal of non-carbon elements without burning the material, converting raw biomass into a functional carbon precursor.

By isolating the peanut shells from oxygen and maintaining strict thermal stability, the furnace facilitates the fundamental chemical shift from organic biomass to a conductive carbon framework suitable for electrode applications.

Creating the Optimal Reaction Environment

Vacuum Protection

The tube furnace isolates the peanut shells from the surrounding atmosphere. According to the specific protocol for KBC, this process utilizes a vacuum-protected environment rather than a flowing inert gas.

This vacuum is critical. It ensures that the high temperatures trigger decomposition rather than combustion, preventing the biomass from turning into ash.

Isothermal Pyrolysis at 600 °C

The furnace is responsible for reaching and maintaining a precise temperature of 600 °C.

This process is isothermal, meaning the temperature remains constant throughout the reaction phase. This stability ensures uniform heating across the biomass sample, leading to consistent material properties.

Mechanisms of Transformation

Dehydration and Devolatilization

Inside the furnace, the thermal energy drives two specific physical-chemical changes: dehydration (removal of moisture) and devolatilization (release of volatile organic compounds).

As the temperature rises, components that are not chemically stable are expelled as gas. This reduces the mass of the peanut shells while retaining the carbon atoms.

Establishing the Preliminary Structure

The ultimate goal of this thermal treatment is structural transformation. The process converts the complex organic structure of the peanut shell into a preliminary carbon structure.

This results in a biochar that serves as a fundamental conductive framework. This framework is the necessary baseline for subsequent processing into electrode materials.

Understanding Process Nuances

Carbonization vs. Activation

It is vital to distinguish this carbonization stage from activation. While supplementary contexts mention using furnaces for etching pores with agents like KOH or CO2, the KBC carbonization stage focuses on stabilization.

This stage builds the "skeleton" of the material. It creates the stable residual biochar that may later be activated to increase surface area, but the tube furnace's role here is primarily establishing the carbon baseline.

Atmosphere Sensitivity

While many biochar protocols utilize inert gases like Nitrogen or Argon, the KBC process specifically relies on a vacuum.

This distinction is important for equipment setup. A vacuum setup reduces convective heat transfer compared to gas flow, relying more on radiation and conduction from the tube walls.

Making the Right Choice for Your Goal

To maximize the effectiveness of the laboratory tube furnace for KBC preparation, align your parameters with your end-goal:

- If your primary focus is Electrode Conductivity: Ensure the furnace maintains a strict 600 °C to fully graphitize the preliminary carbon structure without destroying it.

- If your primary focus is Material Purity: Prioritize the integrity of the vacuum seal to prevent oxygen leakage, which would degrade the carbon yield through oxidation.

The tube furnace is not just a heater; it is the containment vessel that dictates the purity and structural integrity of your final biochar product.

Summary Table:

| Process Parameter | Specification | Function in KBC Preparation |

|---|---|---|

| Temperature | 600 °C | Enables isothermal pyrolysis and preliminary carbon structure formation. |

| Atmosphere | Vacuum-protected | Prevents combustion/oxidation, ensuring high carbon yield. |

| Thermal Phase | Isothermal | Guarantees uniform heating for consistent conductive properties. |

| Reaction Type | Devolatilization | Removes moisture and volatile compounds to establish a carbon skeleton. |

Elevate Your Biochar Research with KINTEK

Precise carbonization requires absolute control over temperature and atmosphere. KINTEK provides industry-leading Tube Furnaces, Vacuum Systems, and CVD solutions designed to meet the rigorous demands of biomass pyrolysis and electrode material development.

Why choose KINTEK?

- Customizable Solutions: Tailored high-temp systems for Muffle, Rotary, and Tube applications.

- Expert Engineering: Backed by advanced R&D and manufacturing to ensure thermal stability.

- Optimized Results: Achieve the exact 600 °C isothermal environment and vacuum integrity your KBC preparation requires.

Ready to transform your laboratory capabilities? Contact KINTEK today to discuss your unique project needs with our technical specialists!

References

- Yujie Wang, Shufa Zhu. Hydrothermal synthesis and electrochemical properties of Sn-based peanut shell biochar electrode materials. DOI: 10.1039/d3ra08655k

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does secondary pyrolysis activation in a tube furnace at 800 °C contribute to the pore structure of APC?

- What core process conditions does a vacuum tube furnace provide for FeCoNiCrAl coatings? Expert Annealing Guide

- What are the controlled atmosphere capabilities of a tube furnace? Unlock Precise Gas Control for Your Lab

- What critical conditions does a high-temperature tube furnace provide for LiFePO4/C? Master Precision Calcination

- Why are controlled atmosphere and vacuum operations important for tube furnaces? Protect Materials and Enable Precision Reactions

- How are tube furnaces utilized in environmental testing? Key Applications for Analysis and Remediation

- What types of atmospheres can a horizontal electric furnace control? Master Material Processing with Precision

- Why is a Horizontal Tube Furnace used for the torrefaction of Refuse Derived Fuel (RDF)? Boost Fuel Efficiency Now