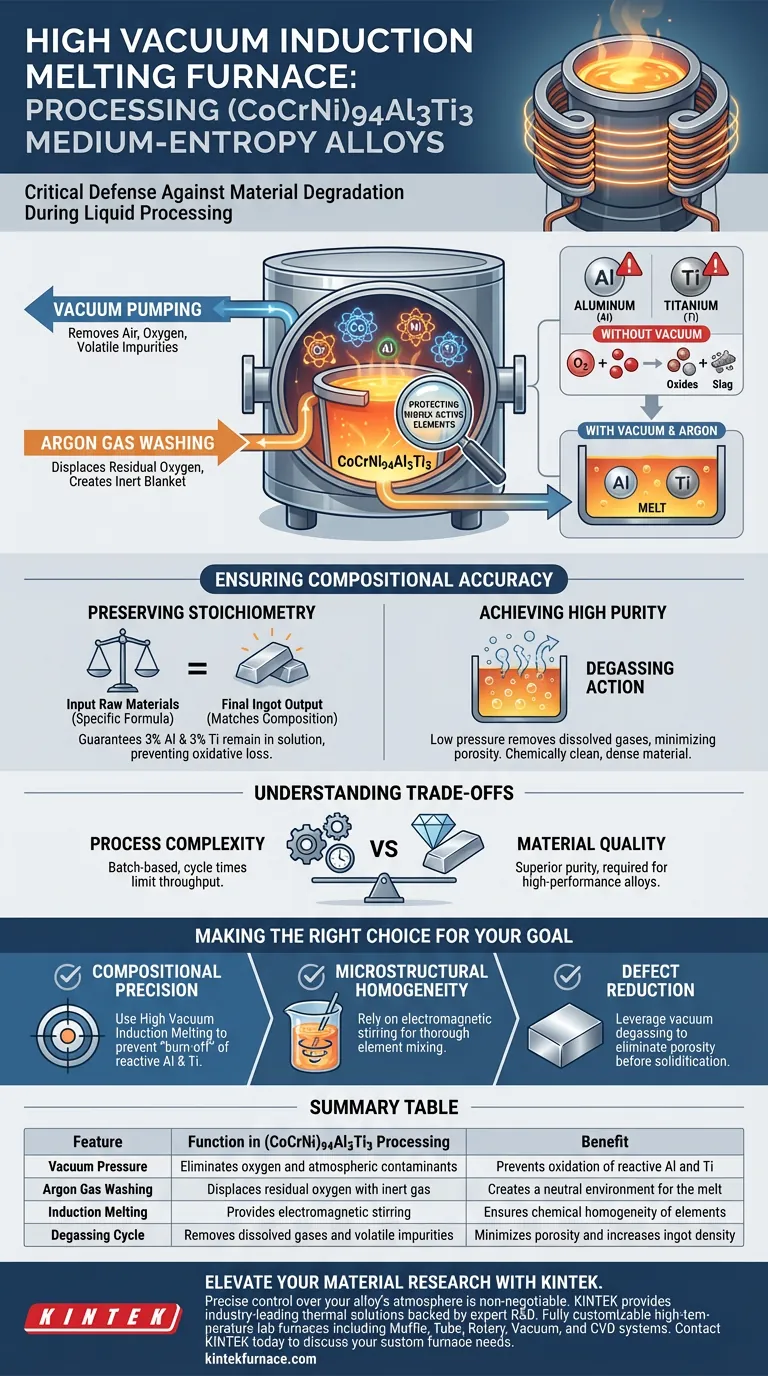

The high vacuum induction melting furnace is the critical defense against material degradation during the liquid processing phase. For the (CoCrNi)94Al3Ti3 medium-entropy alloy, this equipment creates a controlled environment utilizing vacuum pressure and argon gas washing. Its primary function is to eliminate oxygen to prevent the oxidation of highly reactive elements—specifically Aluminum (Al) and Titanium (Ti)—ensuring the alloy retains its precise chemical composition and structural purity.

Core Takeaway Processing (CoCrNi)94Al3Ti3 requires strict atmosphere control because its constituent elements are highly sensitive to oxygen at melting temperatures. The vacuum induction furnace ensures that the theoretical composition matches the actual output by preventing the formation of oxides and slag.

The Critical Need for Atmosphere Control

Protecting Highly Active Elements

The (CoCrNi)94Al3Ti3 alloy contains a mix of transition metals (Cobalt, Chromium, Nickel) and reactive additions (Aluminum, Titanium). At melting temperatures, Aluminum and Titanium are extremely "active," meaning they will aggressively react with any oxygen present to form oxides.

Without a vacuum environment, these elements would essentially burn out of the mixture. This would leave inclusions (impurities) in the metal and alter the target stoichiometry of the final product.

The Role of Argon Gas Washing

Mere vacuum pressure is often not enough; the furnace utilizes argon gas washing to further sanitize the environment. Before melting begins, the system removes air and backfills with inert argon.

This process displaces residual oxygen molecules that vacuum pumping alone might miss. It creates a neutral "blanket" around the melt, ensuring that the molten liquid interacts only with inert gas rather than reactive air.

Ensuring Compositional Accuracy

Preserving Stoichiometry

Medium-entropy alloys rely on precise atomic ratios to achieve their unique mechanical properties. The specific formula (CoCrNi)94Al3Ti3 dictates a delicate balance between the base matrix and the Al/Ti additions.

The furnace ensures that the amount of raw material weighed at the start matches the composition of the final ingot. By preventing oxidative loss, the furnace guarantees that the 3% Aluminum and 3% Titanium content remains in the solution rather than being lost as slag.

Achieving High Purity

Beyond preserving the recipe, the vacuum environment actively removes volatile impurities. The low pressure within the chamber allows gases dissolved in the raw metals or trapped in powder gaps to escape.

This degassing action minimizes porosity in the final casting. The result is a chemically clean, dense material that serves as a reliable foundation for subsequent processing steps, such as heat treatment or mechanical deformation.

Understanding the Trade-offs

Process Complexity vs. Material Quality

While vacuum induction melting is superior for purity, it introduces significant complexity compared to air melting. The process is batch-based and requires strict cycle times for pumping down and backfilling gas, which can limit throughput speed.

The Limits of "Cleaning"

It is important to note that while the furnace prevents new oxidation, it cannot always reverse existing contamination in low-quality raw materials. If the initial feedstock is heavily oxidized, the vacuum furnace may not be able to fully reduce those oxides. High-purity raw materials are still a prerequisite for success.

Making the Right Choice for Your Goal

When selecting a melting process for complex alloys like (CoCrNi)94Al3Ti3, align your equipment choice with your specific metallurgical targets.

- If your primary focus is Compositional Precision: Use high vacuum induction melting to prevent the "burn-off" of reactive elements like Aluminum and Titanium.

- If your primary focus is Microstructural Homogeneity: rely on the electromagnetic stirring inherent in induction furnaces to mix the five different elements thoroughly.

- If your primary focus is Defect Reduction: Leverage the vacuum degassing cycle to eliminate porosity and dissolved gases before the metal solidifies.

The vacuum induction furnace acts not just as a heater, but as a purification chamber that safeguards the specific chemistry required for advanced medium-entropy alloys.

Summary Table:

| Feature | Function in (CoCrNi)94Al3Ti3 Processing | Benefit |

|---|---|---|

| Vacuum Pressure | Eliminates oxygen and atmospheric contaminants | Prevents oxidation of reactive Al and Ti |

| Argon Gas Washing | Displaces residual oxygen with inert gas | Creates a neutral environment for the melt |

| Induction Melting | Provides electromagnetic stirring | Ensures chemical homogeneity of elements |

| Degassing Cycle | Removes dissolved gases and volatile impurities | Minimizes porosity and increases ingot density |

Elevate Your Material Research with KINTEK

Precise control over your alloy’s atmosphere is non-negotiable for high-performance medium-entropy materials. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to your unique research requirements. Stop losing reactive elements to oxidation and start achieving theoretical purity in every melt.

Contact KINTEK today to discuss your custom furnace needs and see how our expertise can streamline your material synthesis.

Visual Guide

References

- Optimized Control of Hot-Working Parameters in Hot-Forged (CoCrNi)94Al3Ti3 Medium-Entropy Alloy. DOI: 10.3390/coatings15060706

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the primary role of vacuum induction melting equipment in the preparation of NiTi alloys? Ensure Nitinol Purity

- What is the core role of a Vacuum Induction Melting (VIM) furnace in ODS steel? Precision Synthesis & Purity

- Why is maintaining a low-pressure vacuum environment necessary during induction heating graphitization?

- What is the role of a medium-frequency vacuum induction furnace? Enhance Purity in High-Strength Spring Steel

- How do IGBT modules function in the melting process? Achieve Efficient, High-Precision Induction Heating

- What are the efficiency benefits of parallel-connected induction coils? Boost Energy Utilization by Over 20%

- What is the purpose of performing multiple argon gas flushing cycles? Ensuring Purity in Sm-Co-Fe Alloy Melting

- What is the output of an induction furnace? Achieve High-Purity, Uniform Molten Metal