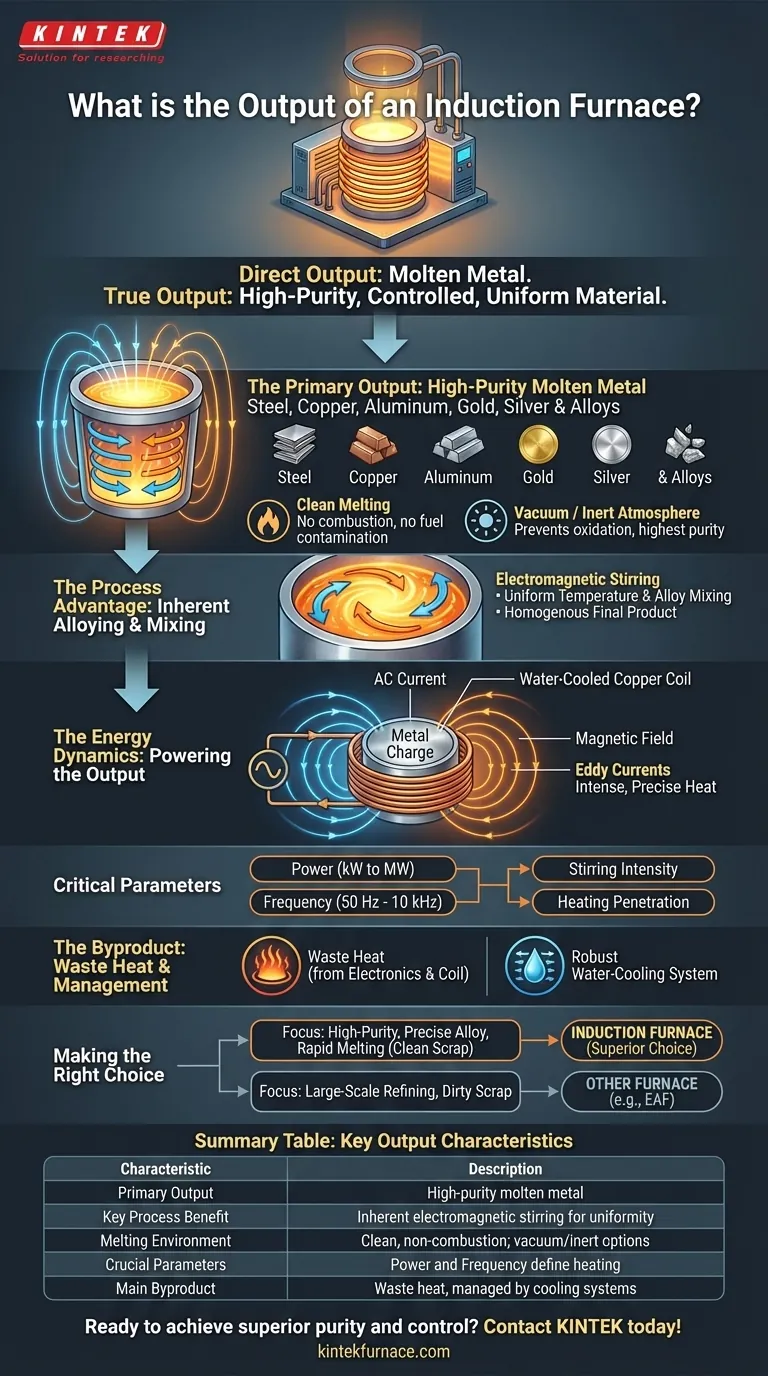

The direct output of an induction furnace is molten metal. This process uses electromagnetic induction to heat and melt conductive materials like steel, copper, aluminum, and precious metals within a controlled container. The characteristics of this output, from its purity to its temperature, are defined by the electrical and physical parameters of the furnace itself.

An induction furnace's true output is not just hot liquid metal, but rather a highly controlled and uniform material. The electromagnetic principles that generate the heat also provide inherent stirring and a clean melting environment, resulting in a product with superior purity and consistency.

The Primary Output: High-Purity Molten Metal

The most visible output is the material that has been melted. However, the quality and characteristics of this material are what distinguish the induction furnace process.

What Materials Can Be Melted?

Induction furnaces are versatile and can be used to melt a wide range of conductive metals.

Common outputs include steel, stainless steel, copper, aluminum, gold, silver, and other specialized alloys. The choice of material depends on the application, from foundries casting parts to facilities producing high-purity ingots.

The Importance of Purity and Control

Unlike fuel-fired furnaces, an induction furnace does not involve combustion. This means no byproducts of burning fuel can contaminate the melt.

This clean melting process can be further enhanced by operating the furnace under a vacuum or in an inert atmosphere (like argon or nitrogen), preventing oxidation and ensuring the highest possible material purity.

Inherent Alloying and Mixing

The powerful, fluctuating magnetic field does more than just heat the metal. It also creates a strong electromagnetic stirring action within the molten bath.

This natural stirring ensures that the temperature is uniform throughout the melt and that any added alloys are mixed in completely, resulting in a homogenous final product without requiring mechanical stirrers.

The Process Output: Understanding the Energy Dynamics

Beyond the molten metal, the process itself has key technical outputs and characteristics that define its operation and efficiency.

How Electromagnetic Induction Creates Heat

The furnace's operation is based on a fundamental electrical principle. Alternating current (AC) flows through a water-cooled copper coil, generating a powerful magnetic field.

This magnetic field induces strong electrical currents, known as eddy currents, directly within the metal charge. The metal's natural resistance to the flow of these currents generates intense, precise heat, causing it to melt.

The Role of Power and Frequency

The key technical outputs that govern this process are power and frequency.

Modern furnaces operate at power levels from a few kilowatts to over 16 megawatts, with frequencies ranging from 50 Hz to 10 kHz. The chosen frequency is critical, as it influences the stirring intensity and how deeply the heating effect penetrates the metal.

The Byproduct: Waste Heat

The process is highly efficient but not perfect. Significant waste heat is generated, primarily in the power supply electronics (like IGBTs or SCRs) and the induction coil itself.

This heat is a critical process byproduct that must be managed. Consequently, both the power supply and the copper coil require robust water-cooling systems to operate safely and effectively.

Understanding the Trade-offs

While powerful, induction technology is not a universal solution. Understanding its limitations is key to using it effectively.

Crucible Selection is Critical

The charge is held in a container called a crucible, which must be made of a refractory material that can withstand extreme temperatures.

If the crucible is non-conductive (ceramic), only the metal is heated. If it is conductive (graphite), the crucible heats up along with the metal. The choice of crucible material is vital to prevent chemical reactions that could contaminate the melt.

Limited Slag Refining Capability

Induction furnaces excel at melting clean scrap and pre-refined materials. The stirring action is less effective for separating large volumes of impurities (slag) from a melt.

For processes that require extensive refining of low-quality, contaminated scrap, other furnace types like the Electric Arc Furnace (EAF) are often better suited.

Power Supply Complexity

The efficiency of an induction furnace relies on a sophisticated, solid-state power supply. These units precisely control the high-frequency current sent to the coil.

While reliable, this technology requires specialized knowledge for maintenance and troubleshooting, representing a different operational challenge compared to simpler combustion-based systems.

Making the Right Choice for Your Goal

The decision to use an induction furnace should be based on a clear understanding of your final product requirements.

- If your primary focus is high-purity melts and precise alloy chemistry: The clean, contained, and self-stirring nature of an induction furnace makes it the superior choice.

- If your primary focus is rapid melting of clean, sorted scrap: An induction furnace offers unmatched speed and energy efficiency for remelting operations.

- If your primary focus is large-scale refining of raw, dirty scrap: You should evaluate whether an Electric Arc Furnace is more appropriate due to its superior ability to manage slag.

Ultimately, understanding that an induction furnace produces a precisely controlled material—not just a generic liquid—is the key to leveraging its full potential.

Summary Table:

| Key Output Characteristic | Description |

|---|---|

| Primary Output | High-purity molten metal (steel, copper, aluminum, precious metals) |

| Key Process Benefit | Inherent electromagnetic stirring ensures uniform temperature and alloy mixing |

| Melting Environment | Clean, non-combustion process; can be vacuum or inert atmosphere for maximum purity |

| Crucial Parameters | Power (kW to MW) and frequency (50 Hz - 10 kHz) define heating and stirring |

| Main Byproduct | Waste heat, managed by robust water-cooling systems for the coil and power supply |

Ready to achieve superior purity and control in your melting process? KINTEK's advanced high-temperature furnace solutions, including our robust induction systems, are engineered for precision. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and foundries with the technology for clean, homogenous melts. Our strong deep customization capability allows us to tailor solutions to your unique material and production requirements.

Contact KINTEK today to discuss how our expertise can enhance your metal melting outcomes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab