The primary purpose of performing multiple argon gas flushing cycles is to systematically purge residual oxygen and moisture from the furnace chamber before the melting process begins. By alternating between high-vacuum pumping and backfilling with ultra-pure argon, you establish a pristine inert atmosphere that prevents the reactive elements in the Sm-Co-Fe alloy from oxidizing.

The core objective is metallurgical integrity: this process eliminates contaminants that would otherwise react with Samarium, thereby preserving the alloy's intended chemical composition and critical magnetic phase structure.

The Chemistry of Contamination

Protecting Reactive Rare Earths

Samarium (Sm), a key component in Sm-Co-Fe alloys, is classified as a highly active metal. It has a strong affinity for oxygen and will react rapidly at high melting temperatures if the atmosphere is not controlled.

The Role of Inert Argon

Argon acts as a protective shield. By filling the chamber with this inert gas, you create a barrier that physically separates the molten metal from any remaining trace contaminants on the furnace walls or in the atmosphere.

Removing Stubborn Moisture

Simple vacuuming is often insufficient to remove water vapor adsorbed onto chamber walls. The flushing cycle—introducing dry argon and then pumping it out again—helps to desorb and carry away this moisture effectively.

Preserving Alloy Performance

preventing Phase Degradation

The formation of oxides, such as Samarium Oxide, is detrimental to the alloy. These oxides are non-magnetic inclusions that disrupt the magnetic phase structure, significantly lowering the final performance of the material.

Ensuring Chemical Accuracy

Precise alloy design relies on specific ratios of Sm, Co, and Fe. If the Samarium is consumed by oxidation (turning into slag rather than staying in the alloy), the final chemical composition will deviate from the design, leading to unpredictable properties.

Common Pitfalls to Avoid

The "Single Cycle" Mistake

A single flush is rarely sufficient to reach the low partial pressures of oxygen required for high-quality magnetic alloys. You must rely on multiple dilution cycles to statistically reduce contaminants to acceptable trace levels.

Argon Purity Levels

The effectiveness of this process is entirely dependent on the quality of the gas used. Using industrial-grade argon rather than ultra-pure argon can inadvertently introduce the very moisture and impurities you are trying to remove.

Making the Right Choice for Your Goal

To ensure the highest quality Sm-Co-Fe production, apply the flushing process with the following goals in mind:

- If your primary focus is Maximum Magnetic Performance: Prioritize the removal of all oxygen to prevent the formation of rare earth oxides that degrade the magnetic phase.

- If your primary focus is Chemical Consistency: Use rigorous flushing to prevent the loss of active elements like Samarium, ensuring your final alloy matches your initial calculations perfectly.

Control the atmosphere, and you control the quality of the alloy.

Summary Table:

| Key Factor | Impact on Sm-Co-Fe Alloys | Role of Argon Flushing |

|---|---|---|

| Oxygen Presence | Forms Sm-oxides, degrading magnetic phase | Displaces oxygen to prevent oxidation |

| Moisture/Water Vapor | Causes contamination and porosity | Desorbs moisture from chamber walls |

| Reactive Elements | Loss of Samarium (Sm) via slag formation | Maintains chemical composition integrity |

| Inclusions | Creates non-magnetic impurities | Ensures a clean, high-purity melt environment |

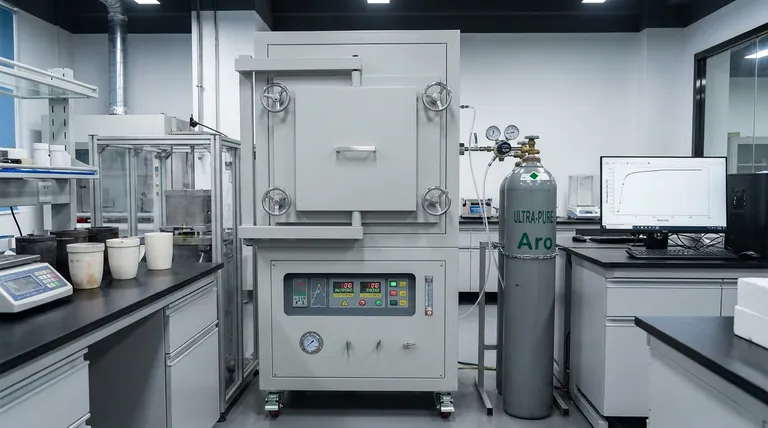

Elevate Your Alloy Quality with KINTEK Precision

Don't let oxidation compromise your magnetic materials. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Tube, and Muffle furnaces specifically designed for sensitive processes like Sm-Co-Fe alloy melting.

Our systems provide the precise atmosphere control needed for rigorous argon flushing cycles, ensuring your alloys maintain their intended chemical accuracy and magnetic performance. Whether you need a standard setup or a customizable system for unique metallurgical needs, KINTEK is your partner in laboratory excellence.

Contact KINTEK today to optimize your melting process!

References

- Zhi Hong Zhu, Jiashuo Zhang. Effect of Fe Content on Phase Behavior of Sm–Co–Fe Alloys During Solidification and Aging. DOI: 10.3390/ma18081854

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in the preparation of medium-manganese hull steel?

- What are the advantages of using medium-frequency induction heating for Ir/HfO2? Boost Coating Purity & Efficiency

- What is the principle of induction heating? Master the Physics of Non-Contact Heating

- What are the raw materials for induction furnace? The Essential Guide to Charge & Construction Materials

- What are the main advantages of using induction heating over other methods? Unlock Speed, Precision & Efficiency

- What are the advantages of an IGBT induction melting furnace for SMEs? Boost Efficiency & Slash Costs

- What are the components and working principle of a coreless induction furnace? Discover Efficient Metal Melting Solutions

- What role do induction furnaces play in IMC-B tests? Precision Melting for High-Purity Steel Simulations