For small and medium-sized enterprises (SMEs), the primary advantages of an IGBT induction melting furnace are significant reductions in energy consumption, faster and more consistent melting cycles, and superior operational reliability. Unlike older technologies, these modern furnaces provide precise control over the melting process while minimizing maintenance and avoiding costly electrical interference with other factory equipment.

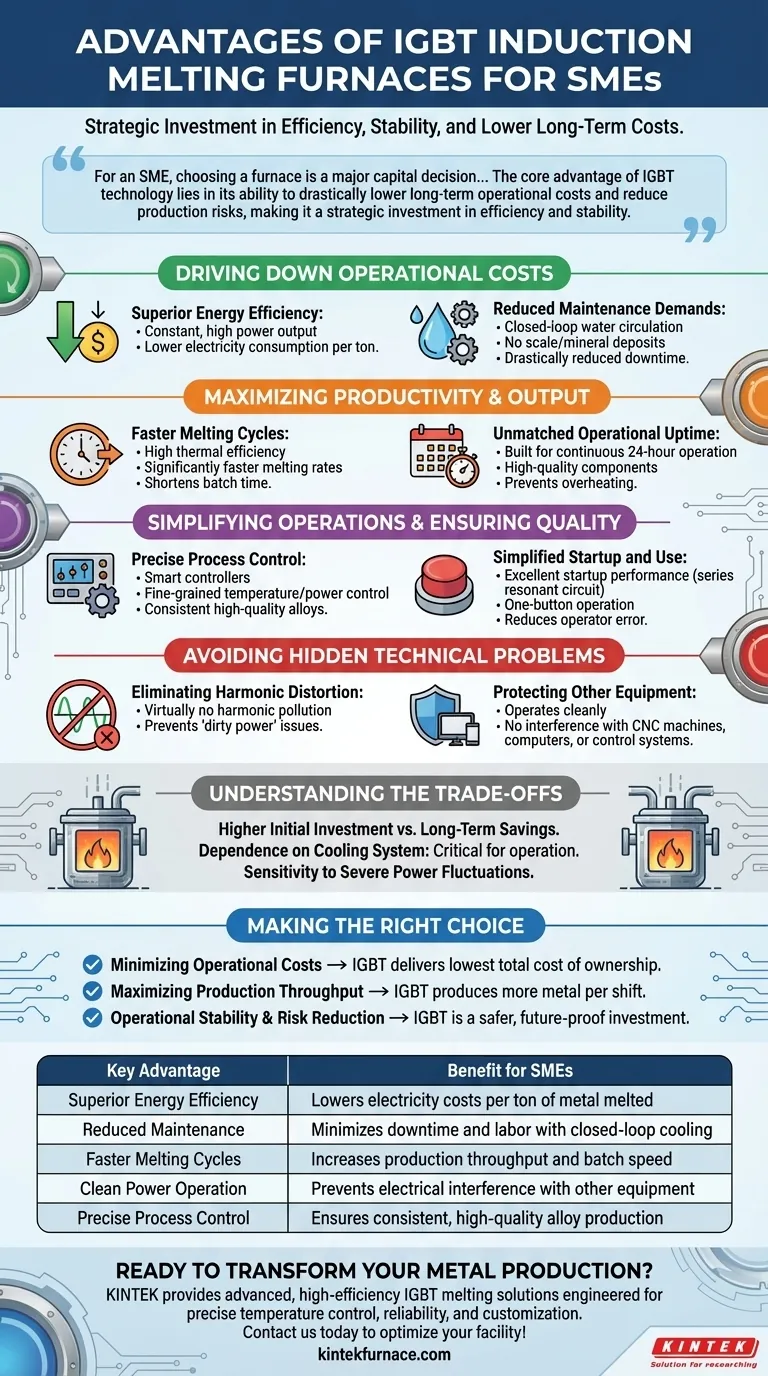

For an SME, choosing a furnace is a major capital decision that extends beyond the initial purchase price. The core advantage of IGBT technology lies in its ability to drastically lower long-term operational costs and reduce production risks, making it a strategic investment in efficiency and stability.

Driving Down Operational Costs

For any SME, managing operational expenditure (OpEx) is critical for profitability. IGBT furnaces are engineered specifically to minimize these ongoing costs through superior design and efficiency.

Superior Energy Efficiency

IGBT (Insulated Gate Bipolar Transistor) technology allows the furnace to maintain a constant, high level of power output throughout the entire melting process. This means it doesn't lose efficiency as the furnace lining wears or the load changes, translating directly into lower electricity consumption per ton of metal melted.

This is a stark contrast to older SCR (Silicon Controlled Rectifier) systems, which can experience power drops and require more energy to complete the same task.

Reduced Maintenance Demands

Modern IGBT furnaces feature a closed-loop water circulation system that uses distilled water and a heat exchanger. This design completely prevents the buildup of scale and mineral deposits inside the critical cooling channels of the power supply and induction coil.

This eliminates a common and costly failure point, drastically reducing downtime, maintenance labor, and the need for periodic descaling procedures.

Maximizing Productivity and Output

An SME's ability to compete often depends on its production throughput. IGBT furnaces are designed to maximize the output from a single unit.

Faster Melting Cycles

The combination of high thermal efficiency and constant power output results in significantly faster melting rates. Whether you are melting iron, steel, copper, or aluminum, the furnace quickly reaches and maintains the target temperature, shortening the time required for each batch.

Unmatched Operational Uptime

These furnaces are built for continuous, 24-hour operation. High-quality components from reputable manufacturers, combined with robust self-protection functions, ensure high reliability. The advanced cooling system further contributes to this by preventing overheating, a common cause of failure in less advanced equipment.

Simplifying Operations and Ensuring Quality

Complex machinery can introduce operational risk and require highly specialized labor. IGBT furnaces are designed to be both powerful and user-friendly.

Precise Process Control

Equipped with smart controllers, IGBT furnaces give operators fine-grained control over melting temperature and power. This precision is essential for producing high-quality alloys and ensuring the final product meets exact metallurgical specifications with minimal variance.

Simplified Startup and Use

IGBT systems feature excellent startup performance, operating reliably on a series resonant circuit. This eliminates the notorious starting difficulties common with older SCR-based furnaces. Often featuring one-button operation, they simplify the process and reduce the potential for operator error.

Understanding the Trade-offs

No technology is without its considerations. An objective evaluation requires acknowledging the potential challenges.

Higher Initial Investment

An IGBT induction furnace typically represents a higher upfront capital cost compared to a traditional SCR-based furnace or a fossil fuel furnace. This investment must be weighed against the long-term savings in energy, maintenance, and productivity.

Dependence on the Cooling System

The highly effective closed-loop cooling system is also the furnace's most critical dependency. While reliable, any failure in this system (such as a pump malfunction or leak) will trigger safety shutdowns, halting production until it is repaired.

Sensitivity to Severe Power Fluctuations

While IGBT furnaces do not pollute the power grid, they can be sensitive to extremely poor incoming power quality. Facilities with highly unstable voltage should ensure adequate power conditioning to protect the furnace's sophisticated electronics.

Avoiding Hidden Technical Problems

A key advantage of IGBT technology is its ability to prevent electrical issues that can disrupt an entire facility.

Eliminating Harmonic Distortion

Older power supplies, particularly SCR units, are known for creating significant harmonic pollution on the electrical grid. This "dirty power" can cause other sensitive electronic equipment in the factory to malfunction, overheat, or fail prematurely. IGBT furnaces operate cleanly, creating virtually no harmonic distortion.

Protecting Other Equipment

By operating cleanly, an IGBT furnace does not interfere with CNC machines, computers, or other control systems. This electrical compatibility is a crucial but often overlooked benefit for a modern, interconnected manufacturing environment.

Making the Right Choice for Your SME

Your final decision should align directly with your company's most important operational goals.

- If your primary focus is minimizing long-term operational costs: The superior energy efficiency and drastically reduced maintenance needs of an IGBT furnace deliver the lowest total cost of ownership.

- If your primary focus is maximizing production throughput: The fast, consistent melting cycles and high uptime of an IGBT system will produce more metal per shift than any alternative.

- If your primary focus is operational stability and risk reduction: The clean power profile and user-friendly, reliable controls make the IGBT furnace a safer and more future-proof investment for your facility.

Ultimately, adopting an IGBT induction furnace is an investment in predictable, efficient, and high-quality metal production.

Summary Table:

| Key Advantage | Benefit for SMEs |

|---|---|

| Superior Energy Efficiency | Lowers electricity costs per ton of metal melted |

| Reduced Maintenance | Minimizes downtime and labor with closed-loop cooling |

| Faster Melting Cycles | Increases production throughput and batch speed |

| Clean Power Operation | Prevents electrical interference with other equipment |

| Precise Process Control | Ensures consistent, high-quality alloy production |

Ready to transform your metal production with an IGBT induction furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide SMEs with advanced, high-efficiency melting solutions. Our furnaces are engineered for precise temperature control, reliability, and deep customization to meet your unique production needs—helping you slash operational costs and maximize output. Contact us today to discuss how our IGBT technology can optimize your facility!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys