At its core, induction heating is a method of generating heat within an electrically conductive object without any physical contact. It accomplishes this by using a powerful, high-frequency alternating current flowing through a coil. This creates a rapidly changing magnetic field that induces electrical currents directly within the material, and the material's own resistance to these currents is what generates precise and instantaneous heat.

The technology operates on a simple but powerful two-step principle: an external magnetic field first induces electrical currents inside a material, and then the material's own resistance converts those currents into targeted, controllable heat. Understanding this two-stage process is the key to mastering its application.

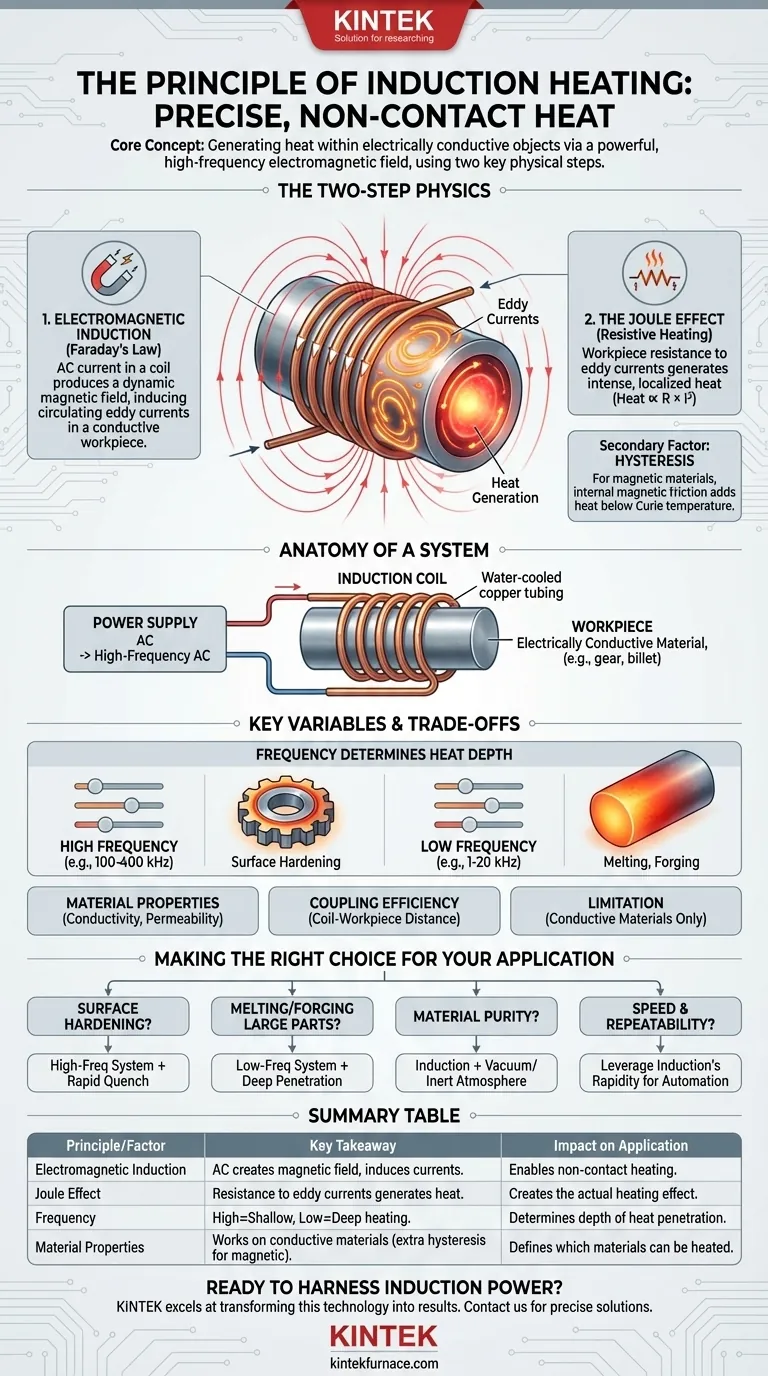

The Two-Step Physics of Induction

Induction heating is not a single phenomenon but the result of two distinct physical principles working in sequence: electromagnetic induction and the Joule effect.

Step 1: Electromagnetic Induction

An induction system begins with an alternating current (AC) passed through an induction coil, typically made of copper. Based on Faraday's Law of Induction, this current produces a dynamic and intense magnetic field in the space around and within the coil.

When an electrically conductive workpiece is placed within this magnetic field, the field induces circulating electrical currents inside the material. These are known as eddy currents.

Step 2: The Joule Effect

Once the eddy currents are flowing within the workpiece, the second principle comes into play. The Joule effect, also known as resistive heating, describes how heat is generated when electricity passes through a conductor.

Every conductive material has some electrical resistance. As the induced eddy currents swirl through the material, they overcome this resistance, and this friction generates intense, localized heat. The heat produced is directly proportional to the material's resistance and the square of the current.

A Secondary Factor: Hysteresis

For magnetic materials like iron, steel, and nickel, there is a secondary source of heat. The rapidly changing magnetic field causes these materials' magnetic domains to quickly flip their orientation. This internal friction generates additional heat, known as hysteresis loss, which contributes to the overall heating effect below the material's Curie temperature.

Anatomy of a Typical System

While the principle is elegant, a practical induction system requires a few key components working in concert.

The Power Supply

This unit converts mains electricity into the high-frequency alternating current required to drive the process. The frequency is a critical variable that dictates the depth of heat penetration.

The Induction Coil

Often made of water-cooled copper tubing, the induction coil (or inductor) is shaped to create a specific magnetic field. Its design—including the number of turns, its diameter, and its proximity to the workpiece—is critical for efficiency and creating the desired heating pattern.

The Workpiece

This is simply the electrically conductive part or material intended for heating. It can be a solid metal billet for forging, a gear for surface hardening, or metal powder in a crucible for melting.

Understanding the Trade-offs and Key Variables

The effectiveness of induction heating is not universal; it depends entirely on manipulating a few key variables. Misunderstanding these can lead to inefficient or ineffective results.

Frequency Determines Heat Depth

This is the most critical variable to control. High frequencies (e.g., 100 kHz to 400 kHz) cause eddy currents to flow near the surface of the workpiece, a phenomenon known as the "skin effect." This is ideal for surface hardening or case hardening.

Conversely, low frequencies (e.g., 1 kHz to 20 kHz) penetrate deeper into the material, generating more uniform, through-and-through heat. This is used for applications like melting or pre-heating large billets before forging.

Material Properties Are Crucial

A material's electrical resistivity and magnetic permeability dictate how it responds to an induction field. Highly resistive materials can heat very quickly. Ferromagnetic materials benefit from the added effect of hysteresis heating, but only up to the point where they lose their magnetic properties (the Curie point).

Coupling Efficiency Matters

"Coupling" refers to the distance between the coil and the workpiece. A tight or close coupling results in a more efficient transfer of energy and a stronger magnetic field. A loose coupling is less efficient but may be required by the geometry of the part.

The Primary Limitation: Conductors Only

Induction heating's greatest strength is also its primary limitation: it only works directly on electrically conductive materials. It cannot heat non-conductors like glass, most ceramics, or plastics. In some cases, a conductive graphite crucible is used as an intermediary to heat non-conductive materials contained within it.

Making the Right Choice for Your Application

You must tailor the induction setup to your specific thermal processing goal.

- If your primary focus is surface hardening or case hardening: Use a high-frequency system to concentrate heat precisely on the outer layer, followed by a rapid quench.

- If your primary focus is melting or forging large parts: Use a lower-frequency system to ensure deep and uniform heat penetration throughout the entire mass.

- If your primary focus is material purity and cleanliness: Pair your induction system with a vacuum or inert gas atmosphere to prevent oxidation and contamination during heating.

- If your primary focus is process speed and repeatability: Leverage induction's rapid, controllable nature, which is perfectly suited for high-volume automated production lines.

By understanding these core principles, you can effectively harness induction heating as a precise and powerful tool for your specific thermal processing needs.

Summary Table:

| Principle/Factor | Key Takeaway | Impact on Application |

|---|---|---|

| Electromagnetic Induction | AC current in a coil creates a magnetic field, inducing eddy currents in a conductive workpiece. | Enables non-contact heating. |

| Joule Effect (Resistive Heating) | The workpiece's resistance to eddy currents generates intense, localized heat. | Creates the actual heating effect. |

| Frequency | High frequency = shallow heating (surface hardening). Low frequency = deep heating (melting). | Determines the depth of heat penetration. |

| Material Properties | Works best on electrically conductive materials; magnetic materials get extra hysteresis heating. | Defines which materials can be heated effectively. |

Ready to Harness the Power of Induction Heating?

Understanding the principle is the first step. Implementing the right solution for your unique thermal processing challenge is the next. KINTEK excels at transforming this advanced technology into real-world results for your laboratory or production line.

Why choose KINTEK? Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Induction Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Let's discuss how we can apply precise, efficient induction heating to your specific application.

Contact our experts today to explore a tailored solution that boosts your efficiency, purity, and repeatability.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing