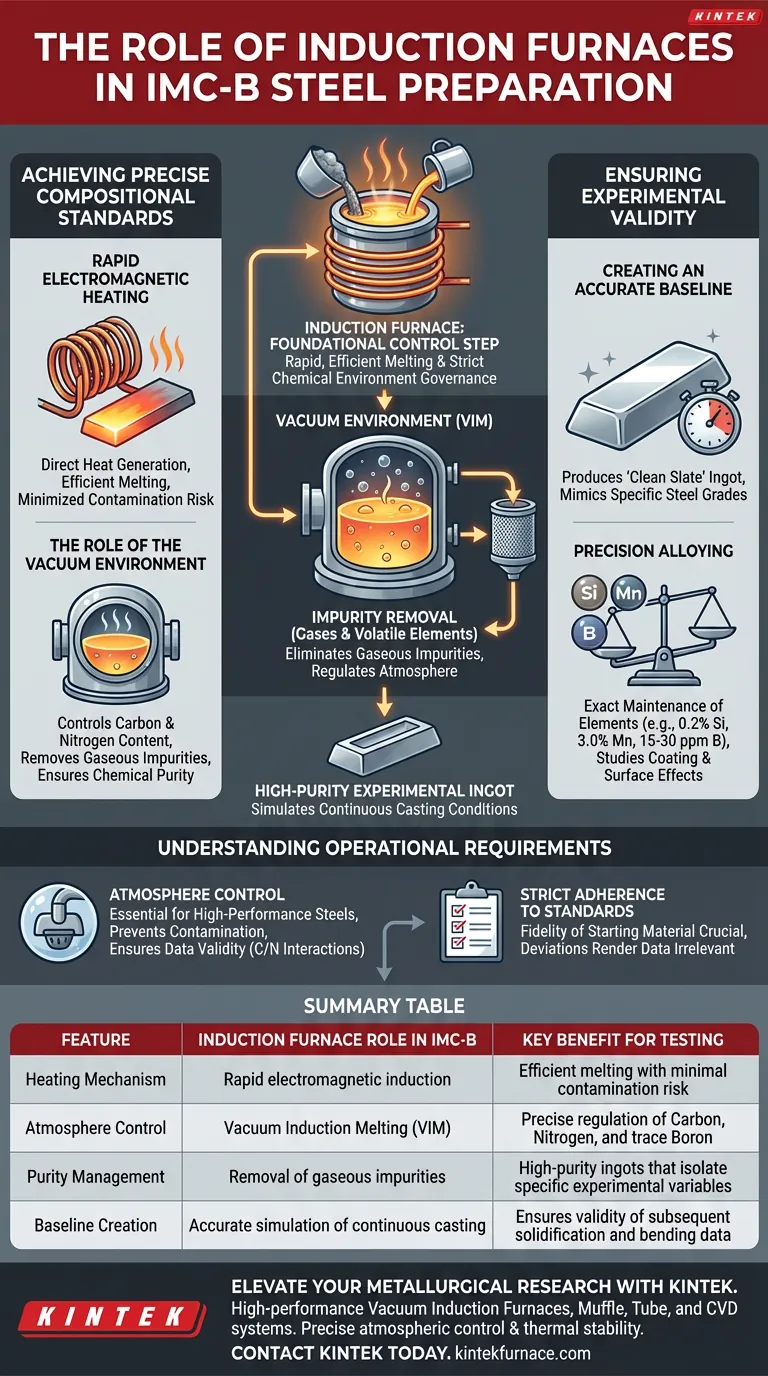

Induction furnaces serve as the foundational control step in preparing steel for In-Situ Melting and Solidification Bending (IMC-B) tests. They are responsible for the rapid, efficient melting of raw materials while strictly governing the chemical environment to ensure the resulting steel meets exact preset standards.

By utilizing a vacuum environment to eliminate gaseous impurities and precisely regulate atmospheric conditions, these furnaces transform raw materials into high-purity experimental ingots that accurately simulate the initial conditions of continuous casting.

Achieving Precise Compositional Standards

Rapid Electromagnetic Heating

Standard induction furnaces utilize electromagnetic induction to generate heat directly within the metal. This mechanism facilitates rapid melting, ensuring the steel reaches the necessary liquid state efficiently without prolonged exposure to potential contaminants.

The Role of the Vacuum Environment

In Vacuum Induction Melting (VIM) furnaces, the melting process occurs within a controlled vacuum. This environment is critical for managing the precise content of gases and volatile elements. It allows researchers to specifically dictate the Carbon and Nitrogen content required for the test logic.

Removal of Impurities

The vacuum environment actively aids in the removal of gaseous impurities from the molten matrix. By lowering the pressure, the system ensures that the final ingot maintains a high level of chemical purity, which is essential for isolating specific variables during testing.

Ensuring Experimental Validity

Creating an Accurate Baseline

The ultimate goal of using these furnaces is to produce a "clean slate" for the IMC-B test. The process ensures that the chemical composition constitutes a highly pure, accurate baseline that mimics the specific grade of steel intended for continuous casting.

Precision Alloying

Beyond basic purity, these furnaces allow for the exact maintenance of alloying elements. For example, researchers can precisely stabilize compositions such as 0.2 mass% Silicon, 3.0 mass% Manganese, and trace Boron additions (15–30 ppm) to study their specific effects on coating properties and surface segregation.

Understanding the Operational Requirements

The Necessity of Atmosphere Control

While standard induction heating provides speed, it is the vacuum capability that provides scientific validity for high-performance steels. Without the vacuum environment, it is nearly impossible to prevent atmospheric contamination that would skew the data regarding Carbon and Nitrogen interactions.

Strict Adherence to Standards

The effectiveness of the IMC-B test is entirely dependent on the fidelity of the starting material. Any deviation in the furnace stage—such as a failure to maintain the vacuum or temperature—will result in an ingot that does not meet preset standards, rendering the subsequent solidification and bending data irrelevant.

Making the Right Choice for Your Goal

To maximize the reliability of your IMC-B data, consider the following requirements regarding furnace selection:

- If your primary focus is Compositional Precision: Prioritize Vacuum Induction Furnaces to strictly control Carbon, Nitrogen, and trace elements like Boron while removing gaseous impurities.

- If your primary focus is Process Efficiency: Rely on the electromagnetic induction mechanism for its ability to rapidly reach melting temperatures and homogenize the melt.

The integrity of your simulation relies entirely on the purity and compositional accuracy achieved during this initial melting stage.

Summary Table:

| Feature | Induction Furnace Role in IMC-B | Key Benefit for Testing |

|---|---|---|

| Heating Mechanism | Rapid electromagnetic induction | Efficient melting with minimal contamination risk |

| Atmosphere Control | Vacuum Induction Melting (VIM) | Precise regulation of Carbon, Nitrogen, and trace Boron |

| Purity Management | Removal of gaseous impurities | High-purity ingots that isolate specific experimental variables |

| Baseline Creation | Accurate simulation of continuous casting | Ensures validity of subsequent solidification and bending data |

Elevate Your Metallurgical Research with KINTEK

Precise IMC-B testing starts with high-purity material preparation. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Vacuum Induction Furnaces, Muffle, Tube, and CVD systems tailored for the most demanding lab environments.

Whether you are simulating continuous casting or developing advanced alloys, our customizable high-temp furnaces deliver the exact atmospheric control and thermal stability your research requires. Contact KINTEK today to discuss your unique furnace needs and discover how our precision engineering can enhance your laboratory's efficiency.

Visual Guide

References

- Investigation on the Susceptibility to Surface Crack Formation in Continuous Casting by a New In Situ Bending Test. DOI: 10.1007/s11663-025-03649-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How does an induction heating furnace compare to a resistance heating furnace in the production of ultrafine magnesium powder? Unlock 20X Higher Yield

- Why Use an Argon Arc Melting Furnace for MnCoNiCuGe5 Alloys? Ensuring Purity in High-Entropy Brazing

- What is the primary function of an induction coil? Mastering Electromagnetic Energy Conversion for Rapid Metal Melting

- Why is precise temperature control in an electric melting furnace essential for AZ91D/Si3N4/WGP composites?

- What are the key components of an IGBT-based induction heater circuit? Unlock Efficient High-Frequency Heating

- What is the primary function of a Vacuum Arc Melting Furnace in the synthesis of Al25CoCrFeNiNd? Ensure Alloy Purity

- Why is a cooling system necessary in an induction heater? Prevent Overheating and Ensure Safe Operation

- What are the major challenges faced by the IGBT induction melting furnace market? Navigating High Costs and Complexity