At its core, an induction heater needs a cooling system because the very process of generating a powerful magnetic field creates significant waste heat within its own electronic components and work coil. This internal heat, if not actively removed, will quickly lead to component damage, system failure, and potential safety hazards.

Induction heating is often perceived as a "cool" technology because it heats a target without flame. However, the immense electrical currents flowing inside the heater itself make it a significant source of internal heat. A cooling system is not an optional add-on; it is a fundamental design requirement for stability, longevity, and safe operation.

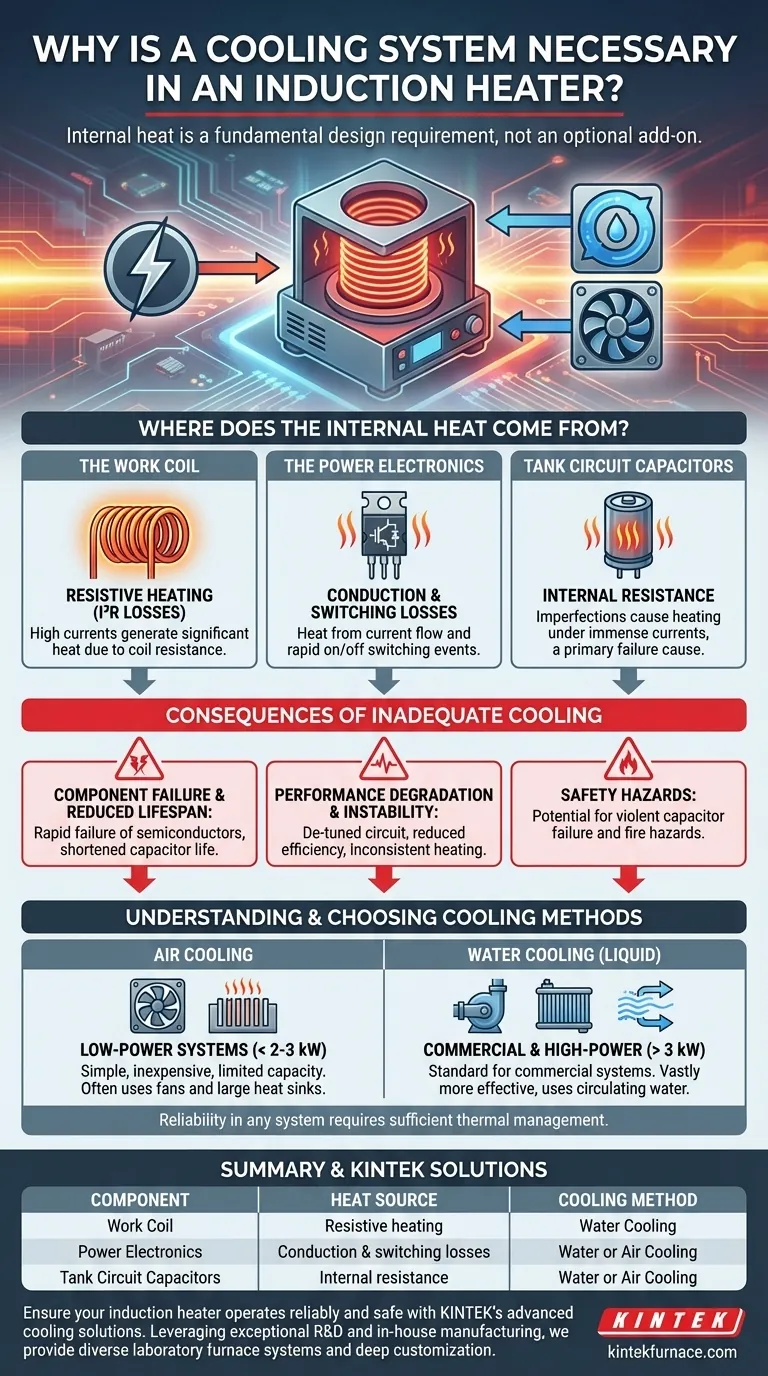

Where Does the Internal Heat Come From?

To understand the need for cooling, you must first understand where this unwanted heat originates. It's a byproduct of electrical resistance and switching inefficiencies in three key areas.

The Work Coil

The work coil, typically made of copper tubing, carries extremely high-frequency, high-amperage currents. While copper is an excellent conductor, it still has some electrical resistance.

This resistance causes resistive heating (also known as I²R losses). The massive current flowing through the coil's small resistance generates a substantial amount of heat, often enough to make the coil glow red if not cooled.

The Power Electronics

The "brain" of the induction heater is its inverter, which uses powerful semiconductor switches (like IGBTs or MOSFETs) to create the high-frequency alternating current.

These switches are not perfectly efficient. They generate heat in two ways:

- Conduction Losses: Heat generated while the switch is on and current is flowing through it.

- Switching Losses: A burst of heat generated each time the switch turns on or off.

At frequencies of tens or hundreds of kilohertz, these switching events happen so rapidly that they create a continuous and intense heat load that must be managed.

The Tank Circuit Capacitors

Capacitors work alongside the coil to create a resonant "tank circuit." These components also handle immense currents.

Internal resistance and imperfections within the capacitor's materials cause them to heat up during operation. Overheating is a primary cause of capacitor failure, which can disable the entire heater.

The Consequences of Inadequate Cooling

Failing to remove this waste heat has immediate and severe consequences for the induction heater's performance and reliability.

Component Failure and Reduced Lifespan

Heat is the primary enemy of all electronic components. For semiconductor switches like IGBTs, exceeding their maximum operating temperature leads to rapid, catastrophic failure.

Even at temperatures below the absolute maximum, sustained heat drastically shortens the lifespan of capacitors, circuit boards, and solder joints, leading to premature and unexpected system failure.

Performance Degradation and Instability

As components get hotter, their electrical properties change. The resistance of the work coil increases, and the capacitance of the capacitors can drift.

This shift can "de-tune" the resonant circuit, reducing the heater's efficiency and power output. The system becomes unstable, delivering inconsistent heating to the workpiece.

Safety Hazards

In a severe overheating scenario, the risks go beyond simple equipment failure. Capacitors can fail violently, and overheated components or wiring can become a serious fire hazard. A robust cooling system is a critical safety feature.

Understanding the Cooling Methods

The choice of cooling system is directly tied to the power and duty cycle of the induction heater.

Air Cooling (Fans and Heat Sinks)

For very low-power systems, typically under 2-3 kilowatts, large heat sinks combined with high-flow fans can sometimes be sufficient.

This approach is simple and inexpensive. However, its ability to remove heat is limited, making it unsuitable for more powerful industrial or continuous-use applications.

Water Cooling (Liquid Cooling)

For nearly all commercial and high-power induction heaters, liquid cooling is the standard. Water is circulated directly through the hollow copper work coil and through "cold plates" mounted to the power electronics.

Water is vastly more effective at absorbing and transferring heat than air. This allows for a much more compact, powerful, and reliable design, as it can efficiently remove the intense heat generated by the system. The trade-off is increased complexity, involving a pump, radiator, and reservoir.

Making the Right Choice for Your System

The cooling strategy must match the system's power level and intended use.

- If your primary focus is a low-power DIY heater (under 2 kW): You can often manage with large, well-ventilated heat sinks and a powerful fan, but you must monitor component temperatures carefully.

- If your primary focus is a high-power or commercial system (>3 kW): A closed-loop water cooling system is non-negotiable for achieving reliable power output and ensuring long-term safety.

- If your primary focus is reliability in any system: Never underestimate your cooling needs; insufficient thermal management is the single most common point of failure in induction heating circuits.

Ultimately, proper cooling is as fundamental to an induction heater's function as the very electronics that power it.

Summary Table:

| Component | Heat Source | Cooling Method |

|---|---|---|

| Work Coil | Resistive heating (I²R losses) | Water cooling (liquid) |

| Power Electronics | Conduction and switching losses | Water cooling (cold plates) or air cooling (fans/heat sinks) |

| Tank Circuit Capacitors | Internal resistance and imperfections | Water cooling or air cooling |

| Consequences of Inadequate Cooling | Component failure, reduced lifespan, performance degradation, safety hazards | Requires robust cooling for stability |

Ensure your induction heater operates reliably and safely with KINTEK's advanced cooling solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your setup with tailored cooling and heating solutions!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Induction Melting Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the principle of a vacuum induction melting furnace based on? Achieve High-Purity Metal Melting

- How does a high-frequency heat induction furnace contribute to the sintering of Titanium-Zirconium alloys?

- How do channel induction furnaces minimize oxidation and decarburization? Achieve Superior Metallurgical Control

- What are the productivity benefits of induction melting furnaces? Transform Your Metal Production Workflow

- Why is a graphite crucible used for melting Ti50Ni47Fe3? Optimize Heat & Efficiency in Vacuum Induction

- How does frequency affect the heating efficiency in an induction furnace? Optimize Your Process with the Right Frequency

- What are the advantages of vacuum induction furnace melting for superalloys? Achieve Purity and Performance

- What are the applications of induction melting? Unlock Precision & Efficiency for Your Metal Processes