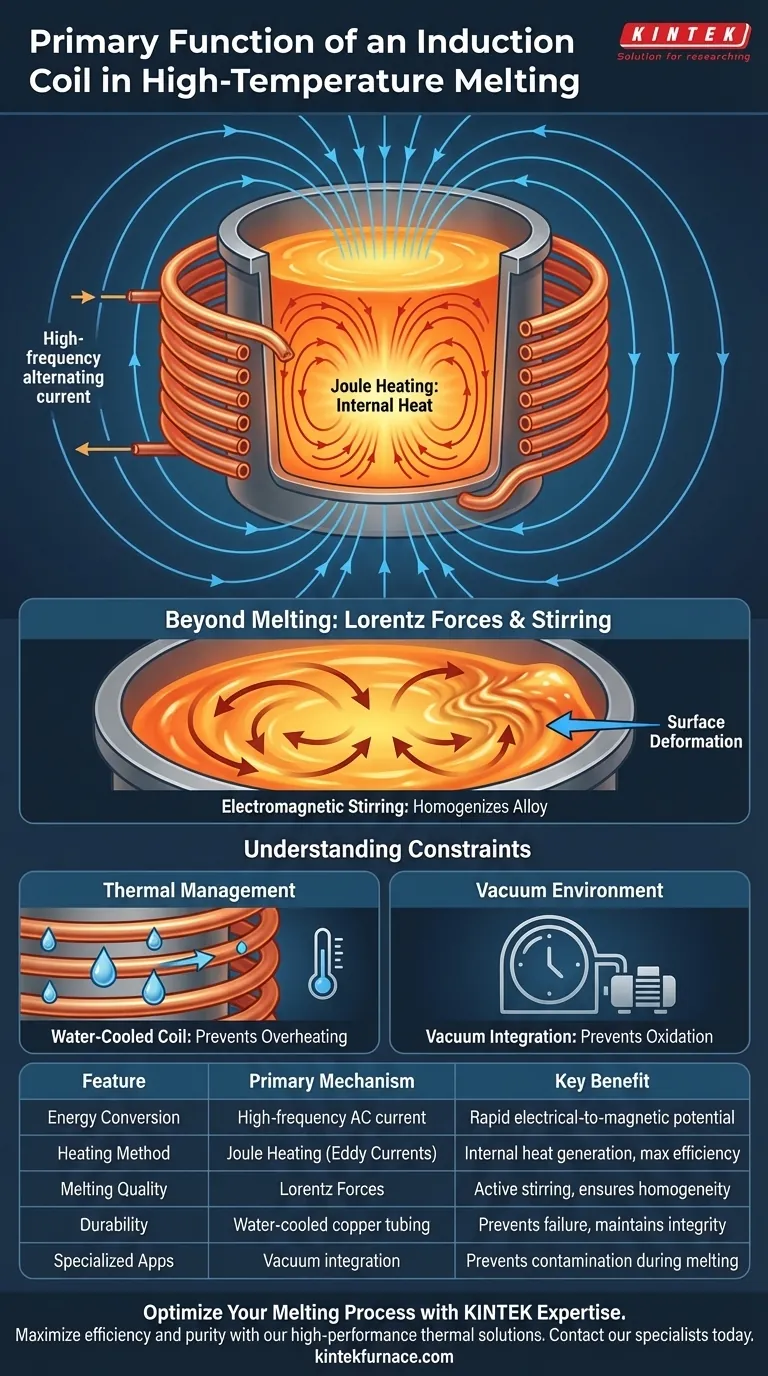

The induction coil functions as the primary engine for electromagnetic energy conversion. It carries high-frequency alternating current to generate an intense alternating magnetic field. This field induces electric currents directly within the metal, driving rapid melting through Joule heating while simultaneously creating Lorentz forces that stir the molten material.

The induction coil is not a heating element in the traditional sense; it is a magnetic field generator. Its defining value lies in its ability to heat metal internally without physical contact while actively agitating the melt to ensure uniformity.

The Mechanics of Energy Conversion

Generating the Magnetic Field

The physical structure of the component is typically a multi-turn coaxial coil, often constructed from copper tubing.

When high-frequency alternating current flows through these turns, it creates a fluctuating magnetic environment. This is the catalyst for the entire melting process, converting electrical energy into magnetic potential.

The Joule Heating Effect

The magnetic field permeates the metallic charge placed within the furnace.

This induction triggers the flow of internal electric currents (eddy currents) within the metal itself. Because the metal resists this current flow, energy is dissipated as heat—a phenomenon known as Joule heating.

Consequently, the metal generates its own heat from the inside out, rather than absorbing it from an external source like a flame.

Beyond Melting: The Role of Lorentz Forces

Electromagnetic Stirring

The function of the coil extends beyond simple temperature elevation.

The interaction between the magnetic field and the induced currents generates Lorentz forces. These forces exert physical pressure on the molten pool, driving a continuous stirring motion.

Surface Deformation

These same electromagnetic forces cause observable changes to the melt's geometry.

The primary reference notes that Lorentz forces are responsible for surface deformation of the melt. This dynamic movement is critical for homogenizing the alloy and ensuring consistent chemical composition throughout the batch.

Understanding the Constraints

Thermal Management Requirements

While the coil generates heat within the metal, the coil itself must not melt.

The supplementary data indicates the coil is usually part of a broader cooling system, often involving water-cooled copper tubing. The trade-off for high-power induction is the absolute necessity of regulating the coil's temperature to prevent system failure or overheating.

Vacuum Environment Dependency

In specific applications, such as vacuum induction melting, the coil's function is isolated from the atmosphere.

It must generate its field through a vacuum chamber designed to prevent oxidation. This adds complexity, as the coil must perform its electromagnetic duties while maintaining strict environmental separation to avoid contaminating the melt.

Making the Right Choice for Your Goal

To maximize the efficiency of your induction furnace, consider how the coil's dual functions align with your specific processing needs:

- If your primary focus is rapid melting: Prioritize high-frequency current delivery to maximize the Joule heating effect for faster cycle times.

- If your primary focus is alloy homogeneity: Focus on the coil's ability to generate strong Lorentz forces, ensuring vigorous electromagnetic stirring for a uniform mix.

The induction coil is the heartbeat of the furnace, simultaneously providing the energy to melt and the force to mix.

Summary Table:

| Feature | Primary Mechanism | Key Benefit |

|---|---|---|

| Energy Conversion | High-frequency AC current | Rapidly transforms electrical energy into magnetic potential. |

| Heating Method | Joule Heating (Eddy Currents) | Heat is generated internally within the metal for maximum efficiency. |

| Melting Quality | Lorentz Forces | Active electromagnetic stirring ensures chemical and thermal homogeneity. |

| Durability | Water-cooled copper tubing | Prevents coil failure and maintains system integrity under high power. |

| Specialized Apps | Vacuum integration | Prevents oxidation and contamination during the melting process. |

Optimize Your Melting Process with KINTEK Expertise

Maximize your laboratory's efficiency and material purity with KINTEK’s high-performance thermal solutions. Backed by expert R&D and world-class manufacturing, we provide a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as advanced induction heating technology tailored to your specific research or production goals. Whether you require rapid melting cycles or precise alloy homogenization, our systems are fully customizable to meet your unique high-temperature needs.

Ready to elevate your material processing? Contact our specialists today to discover how KINTEK can design the perfect furnace solution for your lab.

Visual Guide

References

- Pablo Garcia-Michelena, Xabier Chamorro. Numerical Simulation of Free Surface Deformation and Melt Stirring in Induction Melting Using ALE and Level Set Methods. DOI: 10.3390/ma18010199

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the benefits of the compact and lightweight design of induction furnaces? Maximize Efficiency in Limited Space

- What are the advantages of induction heating over traditional heating methods? Faster, Cleaner, and More Efficient

- What is the role of the vacuum system in a vacuum casting furnace? Ensure Purity and Performance in Metal Casting

- Why is a vacuum electric arc furnace essential for Ti-Al alloys? Achieve Superior Metal Purity & Homogeneity

- Why are induction furnaces considered optimal for aluminum melting? Achieve High Efficiency and Purity

- What is vacuum casting and how does it differ from conventional casting? Ideal for Low-Volume, High-Detail Prototyping

- What is the function of a non-consumable vacuum arc furnace for CoCrFeNiZr0.3 alloys? High-Purity Melting Solutions

- Why are induction furnaces preferred for copper melting applications? Achieve High Efficiency and Superior Quality