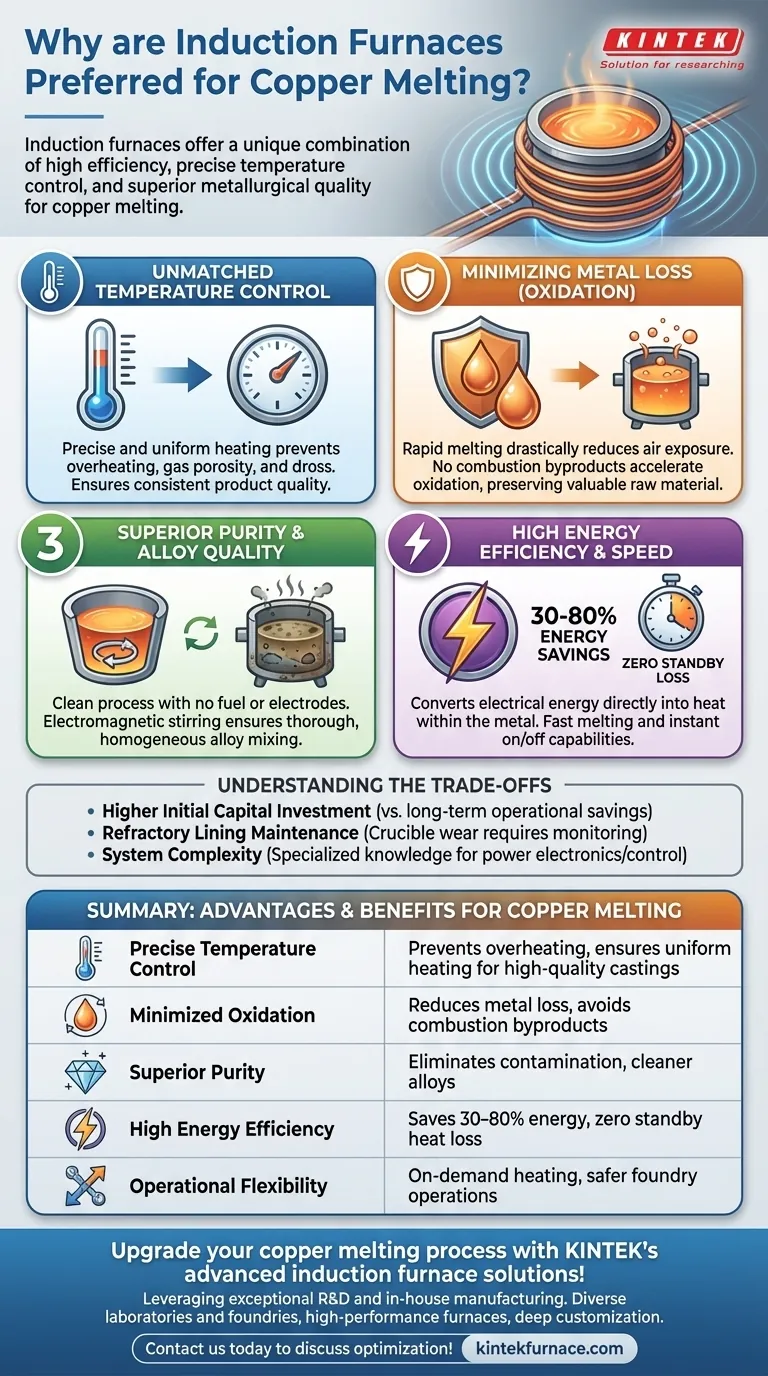

In essence, induction furnaces are preferred for melting copper because they offer a unique combination of high efficiency, precise temperature control, and superior metallurgical quality. This method generates heat directly within the copper itself, minimizing energy waste, reducing the loss of valuable metal to oxidation, and preventing contamination from external fuel sources.

Melting a high-value and highly conductive metal like copper presents a distinct set of challenges. The superiority of induction furnaces lies not in a single feature, but in how their fundamental operating principle directly solves these challenges, leading to significant financial, operational, and quality advantages.

The Core Advantages of Induction for Copper Melting

Induction technology's approach to heating is fundamentally different from traditional fuel-fired or resistance furnaces, and this difference is key to its success with copper.

Unmatched Temperature Control and Consistency

The process works by using an electromagnetic field to induce an electric current directly within the copper, causing it to heat from the inside out. This allows for extremely precise and uniform temperature control, which is critical for preventing overheating, gas porosity, and the formation of unwanted oxides (dross).

This level of control ensures the final cast product meets exact specifications, whether it's a small, custom part or a large bronze structure.

Minimizing Metal Loss (Oxidation)

In conventional furnaces, molten copper is exposed to heat and atmospheric oxygen for extended periods, leading to significant metal loss through oxidation.

Induction furnaces melt copper very rapidly, drastically reducing the time the molten metal is exposed to air. Because the heat is generated internally, there are no combustion byproducts to accelerate oxidation, preserving more of your valuable raw material.

Superior Purity and Alloy Quality

Traditional furnaces introduce the risk of contamination from fuel, combustion gases, or degrading electrodes.

Induction melting is an exceptionally clean process. With no fuel or electrodes involved, there are no external elements to contaminate the melt. The electromagnetic field also creates a natural stirring action, ensuring that alloys are mixed thoroughly and homogeneously for consistent quality.

High Energy Efficiency and Speed

Fuel-fired furnaces lose a tremendous amount of heat to the surrounding environment and require significant time to reach temperature.

Induction furnaces are highly efficient, converting a large percentage of electrical energy directly into heat within the metal. They offer energy savings of 30% to 80% over traditional methods and feature zero standby heat loss, as they can be powered on and off almost instantly.

Understanding the Trade-offs

While induction melting is highly advantageous, it is important to consider the complete picture for a balanced technical assessment.

High Initial Capital Investment

The upfront cost of an induction furnace system, including the power supply, coils, and cooling system, is typically higher than that of a simple fuel-fired furnace. This is a classic trade-off of higher capital expenditure for significantly lower long-term operational expenditure.

Refractory Lining and Maintenance

The crucible (or refractory lining) that holds the molten metal is a critical component that wears over time and requires careful monitoring and periodic replacement. The condition of the lining is paramount for both safety and operational efficiency.

System Complexity

The power electronics and control systems of an induction furnace are more complex than a simple gas burner. This may require more specialized knowledge for troubleshooting and maintenance compared to older, more mechanically straightforward furnace types.

Making the Right Choice for Your Application

Your specific goals will determine how you weigh the benefits of induction melting.

- If your primary focus is cost efficiency and high throughput: The rapid melting rates and substantial energy savings make induction a superior long-term financial investment.

- If your primary focus is high-purity alloys and casting quality: The precise temperature control and contaminant-free nature of induction melting are non-negotiable for meeting strict metallurgical standards.

- If your primary focus is operational flexibility and workplace safety: The on-demand heating and complete elimination of combustible fuel hazards make induction the ideal choice for a modern, adaptable foundry.

Ultimately, choosing an induction furnace is a strategic decision to invest in a process that yields a cleaner, more consistent, and more profitable final product.

Summary Table:

| Advantage | Benefit for Copper Melting |

|---|---|

| Precise Temperature Control | Prevents overheating and ensures uniform heating for high-quality castings |

| Minimized Oxidation | Reduces metal loss by melting rapidly and avoiding combustion byproducts |

| Superior Purity | Eliminates contamination from external sources for cleaner alloys |

| High Energy Efficiency | Saves 30-80% energy with zero standby heat loss and fast melting |

| Operational Flexibility | Enables on-demand heating and safer, adaptable foundry operations |

Upgrade your copper melting process with KINTEK's advanced induction furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and foundries with high-performance furnaces tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Experience enhanced efficiency, purity, and cost savings—contact us today to discuss how we can optimize your operations!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting