At its core, an induction furnace is considered optimal for melting aluminum due to its unique combination of high energy efficiency, precise temperature control, and its ability to preserve the metal's purity. Unlike fuel-fired methods, induction generates heat directly within the aluminum itself, minimizing energy waste and preventing contamination from combustion byproducts, which is critical for producing high-quality alloys.

The true advantage of induction technology for aluminum is not just its efficiency, but its capacity for precise control. This control directly combats aluminum's natural tendency to oxidize, ensuring higher metal yield and superior final product quality.

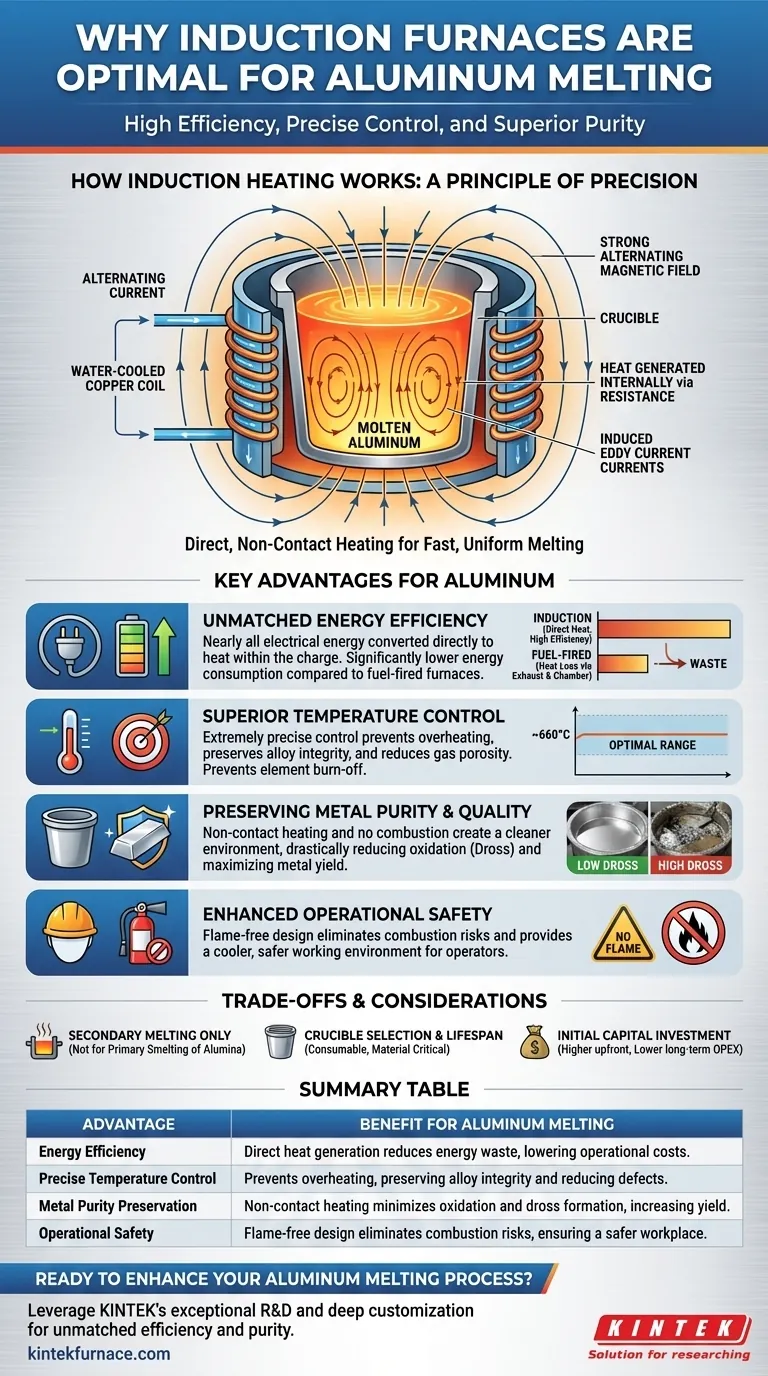

How Induction Heating Works: A Principle of Precision

An induction furnace does not use an external flame or heating element to melt metal. Instead, it relies on a fundamental principle of physics to generate heat from within the material.

The Core Mechanism: Electromagnetic Induction

The furnace consists of a crucible, which holds the aluminum charge, surrounded by a water-cooled copper coil. When a powerful alternating current is passed through this coil, it creates a strong, rapidly changing magnetic field. This magnetic field penetrates the conductive aluminum inside the crucible, inducing powerful electrical currents (known as eddy currents). The aluminum's natural resistance to these currents generates immense heat, causing it to melt quickly and efficiently.

Why This Matters for Aluminum

This method of non-contact heating is exceptionally well-suited for aluminum. Because the heat is generated inside the metal, the melting process is incredibly fast and uniform. This avoids hotspots that can damage the metal and ensures the entire charge reaches the target temperature consistently.

The Key Advantages for Aluminum Melting

Several characteristics of aluminum make induction an ideal technological pairing. The benefits go far beyond simple melting and have a direct impact on operational cost and final product integrity.

Unmatched Energy Efficiency

Induction is one of the most energy-efficient melting methods available. Nearly all the electrical energy is converted directly into heat within the aluminum charge. In contrast, fuel-fired furnaces lose a significant amount of energy heating the furnace chamber, the surrounding air, and through exhaust gases. This direct efficiency translates to lower energy consumption and reduced operational costs.

Superior Temperature Control

Aluminum has a relatively low melting point (~660°C), but its quality degrades quickly if overheated. Excessive temperatures can burn off expensive alloying elements and increase gas porosity in the final casting. Induction systems allow for extremely precise temperature control, ensuring the molten bath is held at the optimal temperature without fluctuation.

Preserving Metal Purity and Quality

Aluminum is highly reactive with oxygen, especially in its molten state. This reaction forms aluminum oxide, or dross, which represents a direct loss of usable metal and can introduce impurities into the melt. Because induction heating does not involve combustion, it creates a much cleaner melting environment with lower oxygen levels, drastically reducing dross formation and maximizing metal yield.

Enhanced Operational Safety

Induction furnaces eliminate the need for storing combustible fuels on-site. The absence of an open flame and hot exhaust gases creates a safer and cooler working environment for operators.

Understanding the Trade-offs and Considerations

While highly effective, induction technology is not without its specific operational requirements and trade-offs. A clear understanding of these points is crucial for a successful implementation.

A Critical Distinction: Melting vs. Smelting

It is important to clarify that induction furnaces are used for secondary melting—melting existing aluminum ingots, scrap, and returns to create alloys or cast parts. They are not used for primary production, which is the process of smelting alumina (aluminum oxide) into pure aluminum. That process, known as the Hall–Héroult process, relies on electrolysis.

Crucible Selection and Lifespan

The crucible is a critical component that contains the molten aluminum. It must be made from a material, such as graphite or a specialized ceramic composite, that can withstand high temperatures and is non-reactive with the aluminum alloy. The crucible is a consumable item, and its selection and lifespan are a key factor in maintenance schedules and operating costs.

Initial Capital Investment

The upfront cost of an induction furnace system can be higher than that of a conventional fuel-fired furnace. However, this initial investment is often offset by lower long-term operating costs due to higher energy efficiency, greater metal yield, and reduced maintenance.

Making the Right Choice for Your Operation

Choosing the right melting technology depends on your specific production goals. An induction furnace is a strategic choice when process control and material quality are paramount.

- If your primary focus is high-purity alloys and maximum yield: The precise temperature control and low-oxidation environment of an induction furnace are unparalleled.

- If your primary focus is energy efficiency and lower operational costs: Induction's direct heating method offers significant long-term savings over most fuel-fired alternatives.

- If your primary focus is operational flexibility and a clean work environment: The compact, flame-free nature of induction systems simplifies installation and significantly improves workplace safety.

Ultimately, choosing an induction furnace is an investment in the control, quality, and long-term efficiency of your aluminum melting process.

Summary Table:

| Advantage | Benefit for Aluminum Melting |

|---|---|

| Energy Efficiency | Direct heat generation reduces energy waste, lowering operational costs. |

| Precise Temperature Control | Prevents overheating, preserving alloy integrity and reducing defects. |

| Metal Purity Preservation | Non-contact heating minimizes oxidation and dross formation, increasing yield. |

| Operational Safety | Flame-free design eliminates combustion risks, ensuring a safer workplace. |

Ready to enhance your aluminum melting process? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today via our contact form to discuss how our induction furnaces can deliver unmatched efficiency and purity for your operations!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More