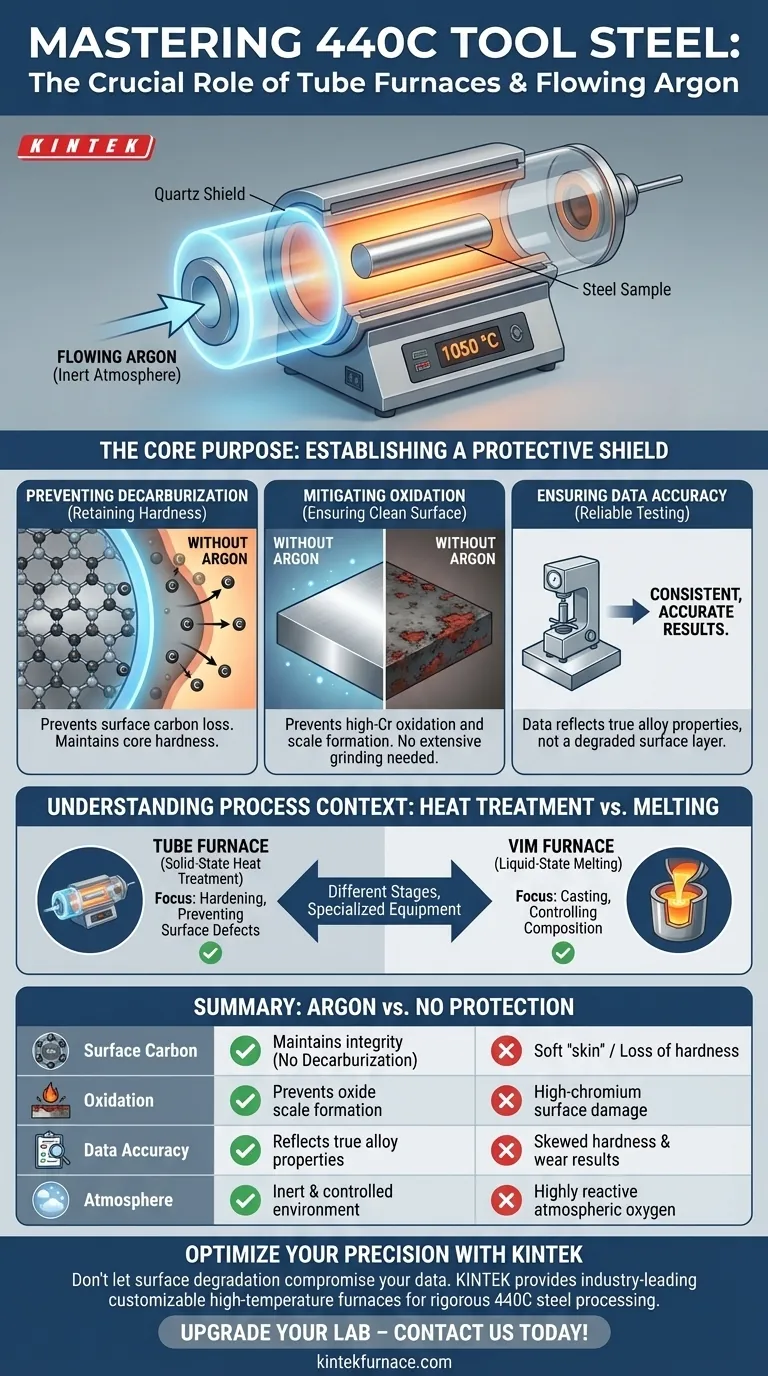

The primary purpose of using a tube furnace with flowing argon is to establish a strictly controlled, inert atmosphere during the high-temperature austenitizing process at 1050 °C. This protection is critical for preventing chemical interactions between the steel surface and the surrounding air, which would otherwise compromise the material's integrity.

Core Takeaway High-chromium steels like 440C are highly reactive at heat treatment temperatures. Flowing argon acts as a protective shield, preventing surface carbon loss (decarburization) and oxidation to ensure that subsequent hardness and wear tests measure the true properties of the alloy, not a degraded surface layer.

Preserving Chemical Integrity at High Heat

The Threat of High Temperatures

Heat treating 440C tool steel requires an austenitizing temperature of approximately 1050 °C.

At this extreme heat, the alloy becomes highly reactive. Without protection, the surface elements—specifically carbon and chromium—will react rapidly with atmospheric oxygen.

Preventing Decarburization

The most critical risk during this phase is decarburization.

This occurs when carbon atoms diffuse out of the steel surface to react with oxygen. Since carbon is the primary element responsible for hardness in 440C steel, losing it results in a soft "skin" on the material. Flowing argon creates a barrier that stops this diffusion, maintaining the correct carbon content right up to the surface.

Mitigating High-Temperature Oxidation

Simultaneously, the argon atmosphere prevents the formation of oxide scales.

440C is a high-chromium steel. While chromium provides corrosion resistance at room temperature, it can oxidize rapidly at 1050 °C if exposed to air. Argon protection ensures the sample emerges from the furnace clean, avoiding surface damage that would require extensive grinding to remove.

Ensuring Accurate Research Data

Consistency for Testing

The ultimate goal of using this setup is to ensure data validity.

For researchers and metallurgists to accurately measure hardness and wear resistance, the surface microstructural state must be consistent with the core material.

Eliminating Surface Variables

If a sample suffers from oxidation or decarburization, test results will be skewed.

By maintaining the surface chemical composition before and after heat treatment, the tube furnace setup guarantees that any performance data reflects the inherent properties of the heat-treated microstructure, not a compromised surface defect.

Understanding the Process Context

Heat Treatment vs. Melting

It is important to distinguish this heat treatment step from the initial material preparation.

While a Vacuum Induction Melting (VIM) furnace is used to prevent oxidation during the melting and casting phase (often at low pressures like 0.133 Pa), the tube furnace is specifically for the solid-state heat treatment phase.

Operational Trade-offs

While flowing argon provides excellent protection, it requires a continuous supply of gas.

Furthermore, the system relies entirely on the integrity of the tube seals. Even a minor leak can introduce enough oxygen to taint the sample surface at 1050 °C, rendering the protection ineffective.

Making the Right Choice for Your Goal

To maximize the reliability of your 440C tool steel processing, align your equipment with your specific processing stage:

- If your primary focus is Heat Treatment (Hardening): Use a tube furnace with flowing argon to prevent surface decarburization and ensure accurate hardness testing results.

- If your primary focus is Material Preparation (Casting): Use a Vacuum Induction Melting (VIM) furnace to control chemical composition and prevent inclusions during the liquid alloy phase.

By strictly controlling the atmosphere during heat treatment, you transform a variable process into a precise scientific standard.

Summary Table:

| Feature | Effect of Argon Protection | Impact Without Protection |

|---|---|---|

| Surface Carbon | Maintains integrity (No Decarburization) | Soft "skin" / Loss of hardness |

| Oxidation | Prevents oxide scale formation | High-chromium surface damage |

| Data Accuracy | Reflects true alloy properties | Skewed hardness & wear results |

| Atmosphere | Inert & controlled environment | Highly reactive atmospheric oxygen |

Optimize Your Heat Treatment Precision with KINTEK

Don't let surface degradation compromise your metallurgical data. KINTEK provides industry-leading Tube, Muffle, and Vacuum systems backed by expert R&D and manufacturing. Our high-temperature furnaces are fully customizable to meet the rigorous demands of 440C steel processing and beyond. Ensure consistent, high-purity results for your lab by partnering with thermal processing experts.

Upgrade your lab’s capabilities—Contact us today!

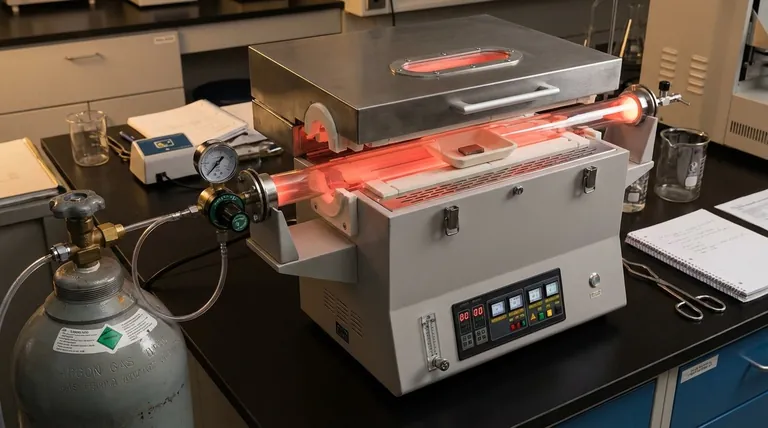

Visual Guide

References

- Vania Rodríguez Herrejon, Venkata Karthik Nadimpalli. Comparative Analysis of Wear Properties of 440C Tool Steel Fabricated by Spray Forming and Conventional Casting. DOI: 10.1007/s11665-025-11860-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of using a high-temperature tube furnace with a steam generator for LOCA simulation?

- How does the hydrogen reduction process in a laboratory tube furnace facilitate the exsolution of nickel species?

- Why is a controlled nitrogen atmosphere essential during the high-temperature processing of biomass in a tube furnace?

- What role does a tube furnace play in the conversion of sludge into biochar? Master Precise Thermal Pyrolysis

- What is the technical significance of the high-temperature environment provided by a tube furnace in the synthesis of Fe3O4@Fe-AC?

- What are the three main types of tube furnaces? Choose the Right One for Your Lab

- What are the disadvantages of tube furnace cracking when processing heavy raw materials? Avoid Costly Downtime and Inefficiency

- What is the function of a multi-zone tube furnace in CVD synthesis? Master 2D In2Se3 Nanosheet Precision