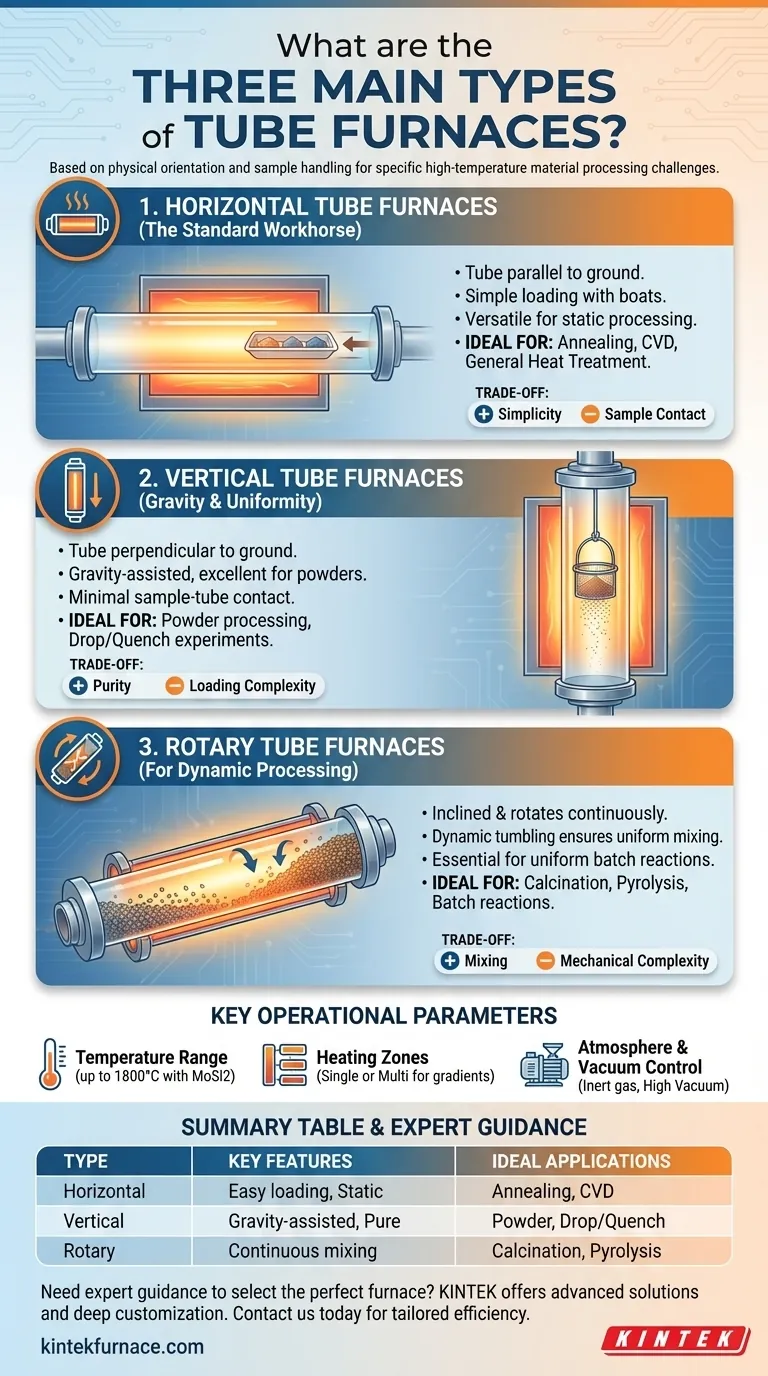

In the world of high-temperature material processing, tube furnaces are primarily categorized into three main types based on their physical orientation and sample handling. The three main types are horizontal, vertical, and rotary tube furnaces. Each design is engineered to solve a specific set of challenges related to sample form, heat transfer, and atmospheric control.

The choice between a horizontal, vertical, or rotary tube furnace is not about superior technology but about aligning the furnace's physical design with the specific requirements of your material and process. Orientation dictates sample containment, atmospheric flow, and heat transfer dynamics.

Understanding the Core Designs

While many features overlap, the fundamental orientation of the process tube is the most critical differentiator. This choice impacts everything from how a sample is loaded to how it interacts with heat and the surrounding atmosphere.

Horizontal Tube Furnaces: The Standard Workhorse

A horizontal tube furnace is the most common configuration. It features a process tube oriented parallel to the ground, with heating elements surrounding it.

Samples, typically held in a ceramic or quartz boat, are slid into the center of the heated zone. This design is straightforward, easy to load and unload, and exceptionally versatile for a wide range of static applications.

Vertical Tube Furnaces: Gravity and Uniformity

In a vertical tube furnace, the process tube is oriented perpendicularly to the ground. Samples can be suspended in the hot zone or loaded from the top to rest on a support.

This orientation uses gravity to its advantage, making it ideal for processing loose powders or granules that need to be contained. It is also the design of choice for experiments involving dropping or quenching samples from a high temperature.

Rotary Tube Furnaces: For Dynamic Processing

A rotary tube furnace is a specialized design where the tube is slightly inclined and rotates during operation. This is also known as a rotary kiln.

The continuous rotation tumbles the material, ensuring every particle is uniformly exposed to the heat and process atmosphere. This dynamic mixing is essential for processes like calcination or pyrolysis where uniform reaction throughout a batch of powder is critical.

Key Operational Parameters to Consider

Beyond the core orientation, several technical parameters define a furnace's capabilities. Understanding these is crucial for matching a furnace to a specific research or production goal.

Temperature Range and Heating Elements

The maximum achievable temperature is determined by the heating element material.

- Kanthal (FeCrAl) alloys are used for temperatures up to 1200°C.

- Silicon Carbide (SiC) elements are common for temperatures up to 1500°C.

- Molybdenum Disilicide (MoSi2) elements are required for the highest temperatures, reaching up to 1800°C.

Heating Zones (Single vs. Multi-Zone)

A single-zone furnace aims to create one uniform area of heat, which is suitable for most standard heat treatments.

A multi-zone furnace (with two, three, or more zones) has independent controllers for different sections of the tube. This allows you to create a precise temperature gradient, which is critical for processes like chemical vapor deposition (CVD) and crystal growth.

Atmosphere and Vacuum Control

Most tube furnaces are designed to operate with controlled atmospheres. Sealing flanges or end caps allow for the introduction of inert gases (like Argon) to prevent oxidation or reactive gases for specific chemical processes.

They can also be connected to a vacuum pump to achieve low (rough vacuum) or high vacuum (down to 10⁻⁵ torr), which is essential for removing atmospheric contaminants.

Understanding the Trade-offs

Each design has inherent strengths and weaknesses. Being aware of them is key to avoiding process failures and making an informed investment.

Horizontal: Simplicity vs. Sample Contact

The primary advantage is simplicity and ease of use. However, the sample rests on the bottom surface of the tube, which can cause it to stick or react with the tube material at high temperatures and may lead to a slight temperature gradient through the sample itself.

Vertical: Purity vs. Loading Complexity

The vertical design is excellent for preventing sample contact with the tube walls and for processing powders that shouldn't be disturbed. The main drawback is that loading and unloading can be more awkward, and the furnace requires more vertical lab space.

Rotary: Mixing vs. Mechanical Complexity

This design offers unparalleled mixing for batch processes. The trade-off is mechanical complexity. The rotating seals required for atmosphere and vacuum control are a potential point of failure and can be more challenging to maintain than a static system.

Making the Right Choice for Your Process

Your final decision must be driven by the physics of your material and the goals of your thermal process.

- If your primary focus is static heat treatment of solid samples or wafers (e.g., annealing, CVD): A horizontal tube furnace offers the simplest and most cost-effective solution.

- If your primary focus is processing powders, preventing sample-tube contact, or performing drop/quench experiments: A vertical tube furnace provides superior control over sample placement and thermal dynamics.

- If your primary focus is achieving uniform reactions throughout a batch of granular material (e.g., calcination): A rotary tube furnace is the only design that provides the necessary continuous mixing.

Ultimately, selecting the correct tube furnace begins with a clear definition of your material's form and your desired processing outcome.

Summary Table:

| Type | Key Features | Ideal Applications |

|---|---|---|

| Horizontal | Easy loading, versatile, static processing | Annealing, CVD, general heat treatment |

| Vertical | Gravity-assisted, minimal sample contact | Powder processing, drop/quench experiments |

| Rotary | Continuous rotation, uniform mixing | Calcination, pyrolysis, batch reactions |

Need expert guidance to select the perfect tube furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your material processing efficiency and outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab