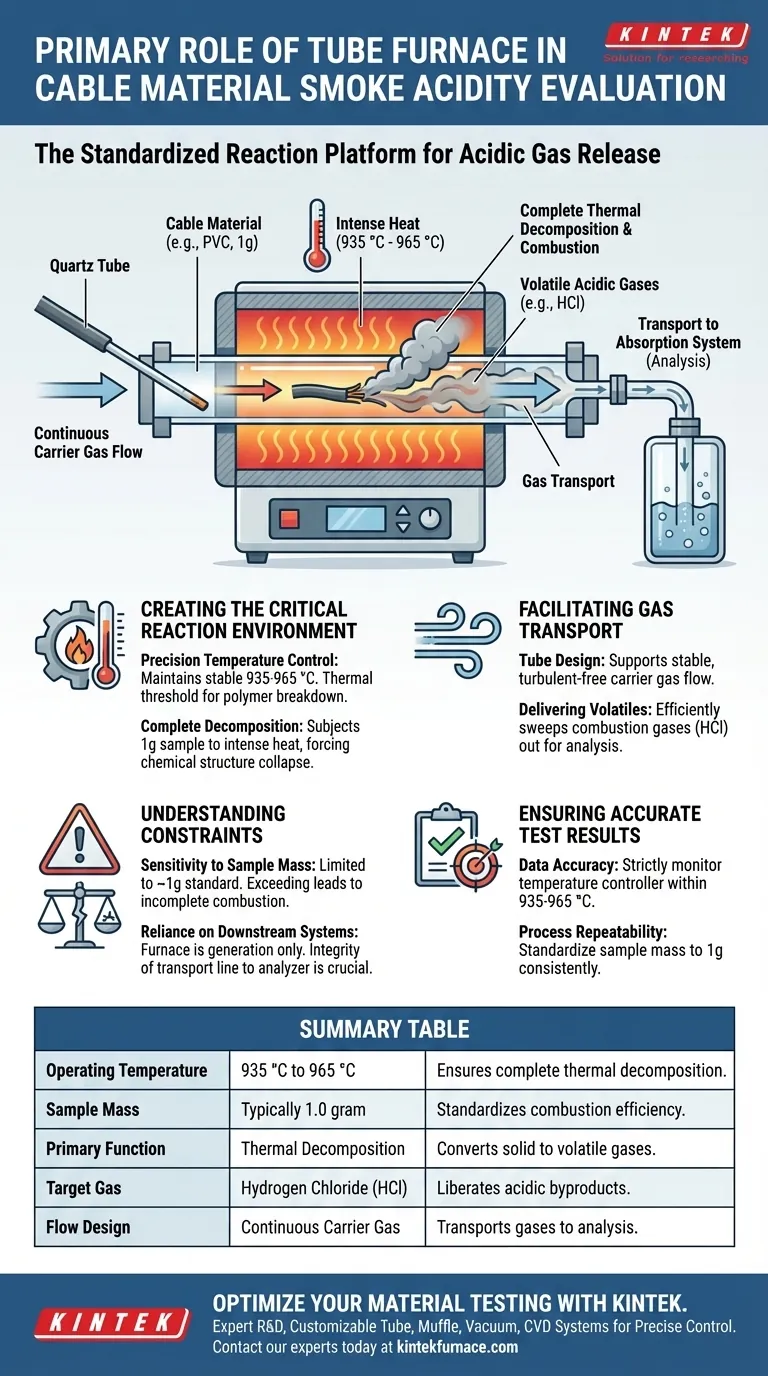

The tube furnace serves as the standardized reaction platform critical for releasing acidic gases from cable materials for testing. Its primary function is to create a precisely controlled high-temperature environment, specifically between 935 °C and 965 °C, which forces the complete thermal decomposition and combustion of a material sample. By maintaining this intense heat, the furnace ensures that volatile components are fully liberated and transported to an absorption system for analysis.

The tube furnace does not measure acidity itself; rather, it acts as the engine of liberation. It ensures that solid materials are converted entirely into combustion gases, allowing for a complete and accurate capture of potential acidic byproducts like hydrogen chloride.

Creating the Critical Reaction Environment

Precision Temperature Control

The furnace provides a highly stable thermal zone that must operate within a strict window of 935 °C to 965 °C.

This range is not arbitrary; it is the thermal threshold required to break down complex polymers used in cabling.

If the temperature drops below this range, the material may only partially degrade, failing to release all acidic compounds.

Complete Thermal Decomposition

The primary goal of this apparatus is to process a specific sample mass, typically 1 gram of material such as a PVC compound.

The furnace subjects this sample to intense heat, ensuring complete combustion rather than simple melting or charring.

This forces the chemical structure of the material to collapse, releasing all bound elements into the gas phase.

Facilitating Gas Transport

The Role of Tube Design

The physical geometry of the furnace tube is designed to support a continuous flow of a carrier gas.

This design creates a stable aerodynamic environment that moves gases away from the combustion zone without turbulence.

Delivering Volatiles for Analysis

As the material decomposes, it releases volatile components, most notably hydrogen chloride (HCl).

The furnace ensures these combustion gases are efficiently swept out of the heated zone.

They are then transported downstream to an absorption system, where the actual acidity quantification takes place.

Understanding the Constraints

Sensitivity to Sample Mass

The tube furnace is calibrated for small, precise quantities, generally limited to the 1-gram standard.

Exceeding this mass can overwhelm the thermal capacity of the specific zone or disrupt the carrier gas flow.

This leads to incomplete combustion ("sooting") and results that under-report the true acidity of the material.

Reliance on Downstream Systems

It is important to recognize that the furnace is only the generation point, not the detection point.

If the connection between the furnace and the absorption system is compromised, gases generated by the furnace will be lost.

Therefore, the furnace's effectiveness is entirely dependent on the integrity of the transport line to the analyzer.

Ensuring Accurate Test Results

To maximize the reliability of your smoke acidity evaluation, focus on the operational parameters of the furnace.

- If your primary focus is Data Accuracy: Strictly monitor the temperature controller to ensure it never drifts outside the 935–965 °C window during the burn.

- If your primary focus is Process Repeatability: Standardize your sample preparation to ensure the mass is consistently 1 gram to prevent fluctuations in combustion efficiency.

Reliable acidity data begins with the complete, controlled destruction of the sample within the tube furnace.

Summary Table:

| Feature | Specification/Requirement | Role in Testing |

|---|---|---|

| Operating Temperature | 935 °C to 965 °C | Ensures complete thermal decomposition of polymers. |

| Sample Mass | Typically 1.0 gram | Standardizes combustion efficiency and gas volume. |

| Primary Function | Thermal Decomposition | Converts solid cable materials into volatile combustion gases. |

| Target Gas | Hydrogen Chloride (HCl) | Liberates acidic byproducts for downstream absorption. |

| Flow Design | Continuous Carrier Gas | Transports gases from the heat zone to the analysis system. |

Optimize Your Material Testing with KINTEK

Precise acidity evaluation starts with a high-performance reaction environment. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Muffle, Vacuum, and CVD systems—all customizable for your unique lab requirements. Our high-temperature furnaces ensure the thermal stability and precise control necessary for standardized cable material testing and polymer decomposition.

Ready to enhance your lab’s accuracy and repeatability?

Contact our experts today to find the perfect furnace solution for your specific needs!

Visual Guide

References

- Iacopo Bassi, Gianluca Sarti. A New Perspective on Hydrogen Chloride Scavenging at High Temperatures for Reducing the Smoke Acidity of PVC in Fires—III: EN 60754-2 and the Species in Solution Affecting pH and Conductivity. DOI: 10.3390/fire8010018

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a vacuum tube furnace? Essential for High-Purity Material Processing

- What is a high temperature tube furnace? Achieve Precise Heat and Atmosphere Control

- What is the purpose of using a high-temperature tube furnace with an argon atmosphere during carbonization?

- How is an electric tubular furnace defined and what are its main functions? Unlock Precision Heating for Your Lab

- What critical physical environment does a tube furnace provide for iron ore? Master Precision Reduction Control

- What is the specific role of a Tube Furnace in the synthesis of sodium cobalt borate (NCBO)? Achieve Pure Crystals

- Why are sealed quartz tubes required for TMD synthesis? Ensure Pure MoS2 & WS2 Growth

- What technical advantages do three-zone tube furnaces offer? Superior Temperature Control and Flexibility