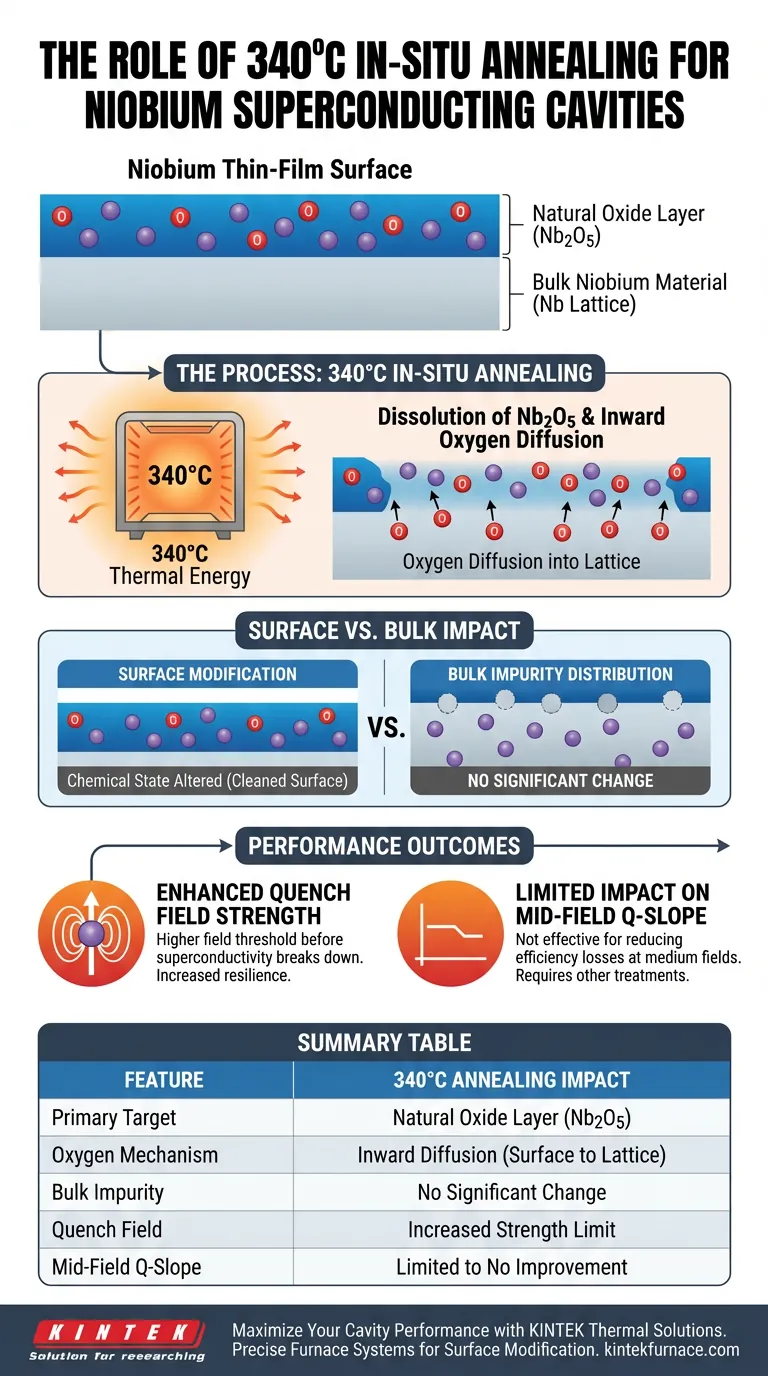

The primary purpose of 340°C in-situ annealing is to actively dissolve the natural oxide layer, specifically Nb2O5, residing on the surface of niobium thin films. This thermal treatment provides sufficient energy to facilitate the diffusion of oxygen atoms from the surface into the material's interior, fundamentally altering the surface chemical state.

By targeting surface oxides without altering the bulk impurity distribution, this specific annealing process serves as a method to increase the initial quench field strength of the cavity.

The Mechanism of Surface Modification

Dissolution of Nb2O5

The critical function of the 340°C set point is the breakdown of the natural oxide layer.

Niobium forms a stable oxide, Nb2O5, when exposed to air. This annealing process effectively "cleans" the surface by dissolving this specific compound.

Oxygen Diffusion Dynamics

Rather than removing the oxygen from the system entirely, the heat drives it inward.

The thermal energy allows oxygen atoms to migrate from the surface skin into the deeper lattice of the film. This redistribution changes the chemical composition of the surface layer.

Surface vs. Bulk Impact

It is vital to distinguish between surface treatment and bulk restructuring.

At 340°C, the thermal energy is insufficient to alter the bulk impurity distribution of the film. The changes are strictly confined to surface chemistry and near-surface diffusion.

Performance Outcomes

Enhancing Quench Field Strength

The direct benefit of dissolving the oxide layer is an improvement in the cavity's electromagnetic resilience.

The process contributes to an initial increase in the quench field strength. This allows the cavity to sustain higher accelerating fields before losing its superconducting state.

Understanding the Limitations

Limited Impact on Mid-Field Q-Slope

While effective for surface oxides, this technique is not a comprehensive solution for all performance metrics.

The primary reference indicates that 340°C annealing has a limited impact on reducing the mid-field Q-slope.

If your objective is to mitigate efficiency losses at medium field strengths, this specific thermal treatment may not yield significant results.

Making the Right Choice for Your Goal

When deciding whether to implement 340°C in-situ annealing, consider your specific performance targets:

- If your primary focus is increasing Quench Field Strength: Utilize this annealing temperature to dissolve surface oxides and improve the field threshold at which superconductivity breaks down.

- If your primary focus is reducing Mid-Field Q-Slope: Recognize that this method has limited efficacy for this specific metric and may need to be combined with or replaced by other treatments.

Understanding the distinction between surface oxide dissolution and bulk property modification is the key to predicting cavity performance.

Summary Table:

| Feature | 340°C In-Situ Annealing Impact |

|---|---|

| Primary Target | Natural oxide layer (Nb2O5) dissolution |

| Oxygen Mechanism | Inward diffusion from surface to lattice |

| Bulk Impurity | No significant change in distribution |

| Quench Field | Increased field strength limit |

| Mid-Field Q-Slope | Limited to no improvement |

Maximize Your Cavity Performance with KINTEK

Are you looking to optimize the electromagnetic resilience of your superconducting components? KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Whether you need precise Muffle, Tube, or Vacuum furnace systems, our technology is customizable to meet the exacting 340°C requirements for niobium thin-film surface modification.

Don't let surface oxides limit your acceleration thresholds. Contact us today to discuss your unique lab high-temp furnace needs and see how our specialized equipment can enhance your material science outcomes!

Visual Guide

References

- Bektur Abdisatarov, Anna Grassellino. Optimizing superconducting Nb film cavities by mitigating medium-field <i>Q</i>-slope through annealing. DOI: 10.1088/1361-6668/ade635

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What gas is used in graphite furnace? Argon vs. Nitrogen for Optimal GF-AAS Performance

- Why is high-purity argon used to fill a vacuum furnace during diffusion coating? Prevent High-Temperature Oxidation

- What are the key steps in a typical vacuum brazing treatment? Master the Process for Strong, Clean Joints

- Why must a vacuum system maintain a high vacuum during Al2O3-TiC sintering? Ensure Material Integrity & Density

- How does vacuum degree affect the sintering atmosphere? Optimize Material Purity and Performance

- Why Must SiC Sintering Use Vacuum or Argon? Prevent Oxidation and Ensure Maximum Ceramic Density

- Why is it necessary to maintain a high vacuum for PrVSb3 single crystal preparation? Ensure Purity and Stoichiometry

- Why is a water cooling system necessary in a vacuum furnace? Ensure Safety and Performance in High-Temp Processes