The function of a cold tube furnace for magnesium extraction is to facilitate the evaporation and subsequent condensation of magnesium within a strictly controlled, high-purity environment. Its operation hinges on an integrated vacuum pump system that evacuates the chamber to pressures below 5 Pa, ensuring the process occurs without the interference of atmospheric gases.

The device separates magnesium from raw materials by creating an ultra-clean vacuum loop. Its core value lies in preventing oxidation before it begins, ensuring the final magnesium product remains pure during the transition from solid to vapor and back to solid.

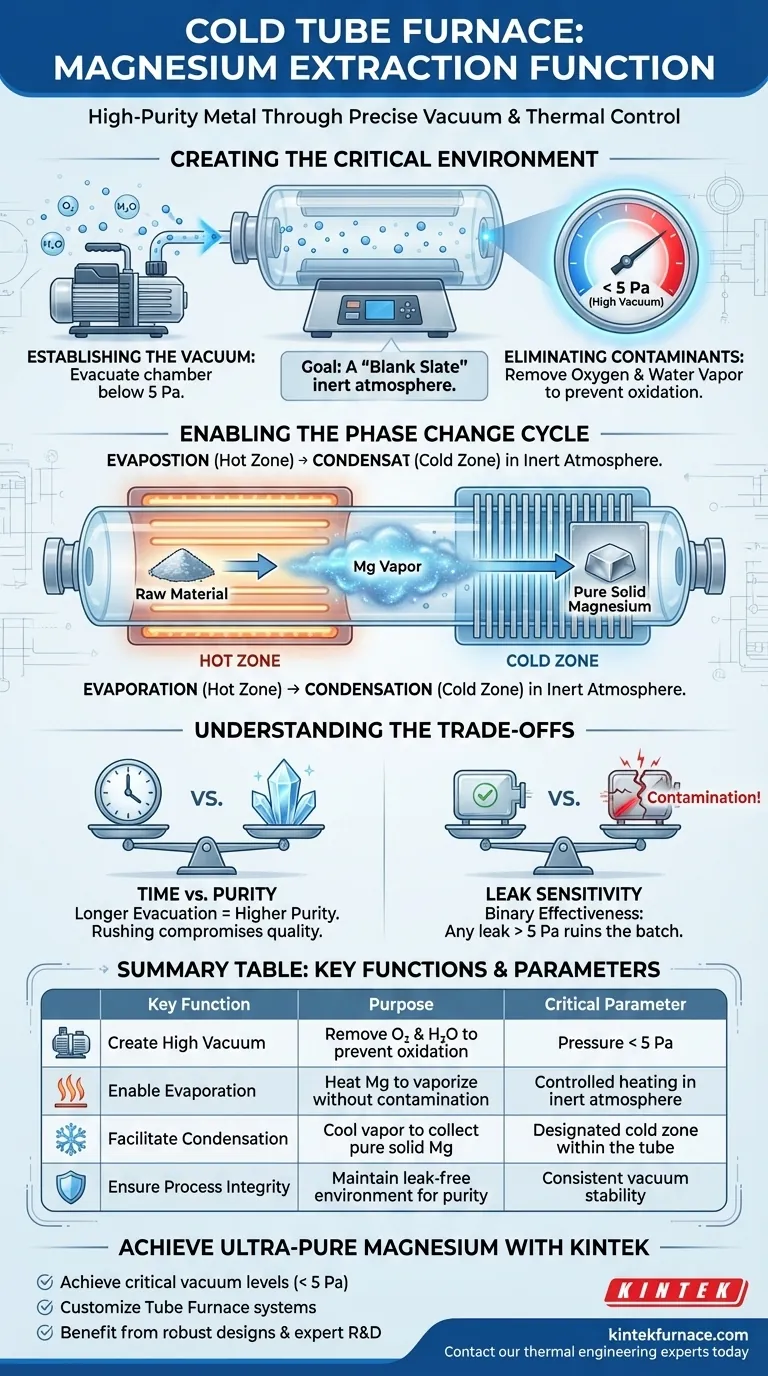

Creating the Critical Process Environment

To understand the furnace's function, one must look beyond the heating element and focus on the atmospheric control system. This is the mechanism that determines the success of the extraction.

Establishing the Vacuum

The initial phase of operation is the most critical. Before any heating occurs, the system utilizes a high-performance vacuum pump to evacuate the internal chamber.

The goal is to reach a vacuum level below 5 Pa. This is not merely about lowering pressure; it is about physically removing the medium in which chemical reactions typically occur.

Eliminating Contaminants

The primary adversaries in magnesium extraction are oxygen and water vapor. If these are present when the temperature rises, the magnesium will oxidize immediately rather than evaporate purely.

The furnace functions as a decontamination chamber. By removing residual air, it ensures the raw materials are processed in a "blank slate" environment, stripping away the potential for immediate chemical degradation.

Enabling the Phase Change Cycle

Once the environment is secured, the furnace facilitates an evaporation-condensation process.

Because the chamber is an inert atmosphere, magnesium can evaporate from the raw material without reacting with the air. It then travels to the "cold" zone of the tube, where it condenses back into a solid, purified metal.

Understanding the Trade-offs

While the cold tube furnace offers high purity, reliance on a vacuum system introduces specific operational constraints that must be managed.

Sensitivity to Leaks

The system's effectiveness is binary: it either holds the vacuum, or it fails. Even a microscopic leak that raises the pressure above 5 Pa introduces oxygen, which will contaminate the entire batch of magnesium.

Processing Time vs. Purity

Achieving a deep vacuum (below 5 Pa) requires time before the heating cycle can even begin.

Operators must trade production speed for quality. Rushing the evacuation phase to start heating sooner will leave residual water vapor in the chamber, compromising the integrity of the extraction.

Making the Right Choice for Your Goal

When utilizing a cold tube furnace, your operational parameters should be dictated by your specific requirements for the final material.

- If your primary focus is Maximum Purity: Prioritize the pre-heating evacuation phase, ensuring the vacuum stabilizes well below 5 Pa to eliminate all traces of water vapor.

- If your primary focus is Process Efficiency: Invest in high-capacity vacuum pumps that can reach the target pressure rapidly, reducing the downtime between the loading and heating phases.

A cold tube furnace is not just a heating device; it is a vacuum chamber that uses heat to isolate and purify metal at the molecular level.

Summary Table:

| Key Function | Purpose | Critical Parameter |

|---|---|---|

| Create High Vacuum | Remove oxygen & water vapor to prevent oxidation | Pressure < 5 Pa |

| Enable Evaporation | Heat magnesium to vaporize it without contamination | Controlled heating in inert atmosphere |

| Facilitate Condensation | Cool vapor to collect pure, solid magnesium | Designated cold zone within the tube |

| Ensure Process Integrity | Maintain a leak-free environment for batch purity | Consistent vacuum stability |

Need ultra-pure magnesium for your research or production?

The precise vacuum control and contamination-free environment of a cold tube furnace are essential for successful high-purity metal extraction. At KINTEK, we specialize in advanced thermal solutions for demanding applications.

Our expertise can help you:

- Achieve the critical vacuum levels (< 5 Pa) necessary for oxidation-free processing.

- Customize a Tube Furnace system tailored to your specific magnesium extraction parameters and throughput needs.

- Benefit from robust designs backed by expert R&D and manufacturing.

Let's discuss your project requirements. Contact our thermal engineering experts today to explore how a KINTEK solution can enhance your lab's capabilities and ensure the purity of your materials.

Visual Guide

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What factors should be considered when selecting between a tube furnace and a box furnace? Optimize Your Lab's Thermal Processing

- What conditions does a tube furnace provide for post-ion-implantation? Achieve Precise Microstructural Repair

- What is the difference between a vacuum tube furnace and a standard tube furnace? Choose the Right Furnace for Your Lab

- What is the mechanism of the drive-in process in a tube furnace? Master Dopant Redistribution with Nitrogen Shielding

- Why is the iodine source placed at the upstream end of the tube furnace? Optimizing I-NC Chemical Vapor Deposition

- How does a dual-zone tube furnace facilitate monolayer synthesis? Precision Growth for MoS2 & WS2

- What additional features can tube furnaces have? Enhance Your Lab with Advanced Control and Customization

- What certifications are associated with three-zone split tube furnaces? Key Marks for Quality and Safety