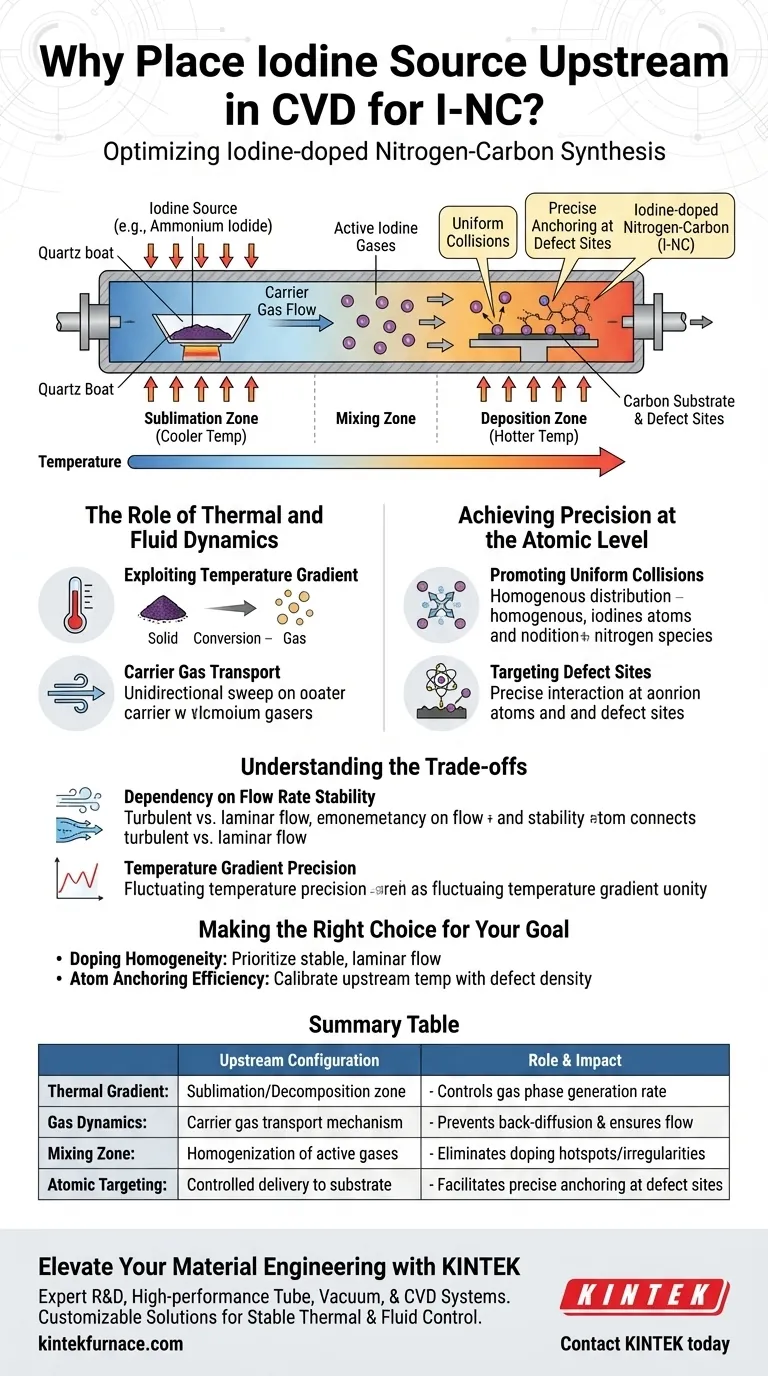

Placing the iodine source at the upstream end of the tube furnace is a critical configuration designed to optimize the transport and reaction mechanics of the Chemical Vapor Deposition (CVD) process. By positioning the source material—typically ammonium iodide—in this zone, you ensure it enters a phase of sublimation or decomposition to generate active gases. These gases are then effectively transported by the carrier gas to the carbon substrate located downstream.

This configuration utilizes the furnace's stable temperature gradient to decouple the vaporization of the source from the deposition process, ensuring iodine atoms are delivered uniformly to anchor precisely onto the carbon skeleton.

The Role of Thermal and Fluid Dynamics

Exploiting the Temperature Gradient

The tube furnace is not a uniform thermal environment; it is utilized to create a stable gradient temperature field.

Placing the iodine source upstream exposes it to a specific thermal zone designed to promote sublimation or decomposition. This ensures the solid source is efficiently converted into the active gaseous species required for doping.

Carrier Gas as a Transport Mechanism

Once the iodine source is vaporized, it requires a delivery vehicle to reach the target substrate.

The continuous flow of carrier gas sweeps these active iodine gases from the upstream section to the downstream center. This unidirectional flow prevents back-diffusion and ensures a constant supply of reactants to the carbon scaffold.

Achieving Precision at the Atomic Level

Promoting Uniform Collisions

The separation distance between the source and the substrate allows for the homogenization of the gas mixture.

As the active gases travel downstream, they mix thoroughly with the carrier gas. This ensures that when the iodine atoms finally reach the carbon substrate, they collide with it uniformly rather than creating concentrated "hotspots" of doping.

Targeting Defect Sites

The ultimate goal of this process is the synthesis of Iodine-doped Nitrogen-Carbon (I-NC) with high structural integrity.

The uniform delivery allows iodine atoms to interact effectively with defect sites on the carbon skeleton. This controlled interaction facilitates the precise anchoring of iodine single atoms, stabilizing them within the material structure.

Understanding the Trade-offs

Dependency on Flow Rate Stability

While this setup promotes uniformity, it makes the process highly sensitive to carrier gas fluid dynamics.

If the gas flow is too turbulent or too fast, the iodine species may pass the substrate without sufficient residence time to react. Conversely, if the flow is too slow, the transport may be inefficient, leading to premature deposition.

Temperature Gradient Precision

The success of this method relies heavily on maintaining a specific and stable difference between the upstream and downstream zones.

If the upstream temperature fluctuates, the rate of sublimation will vary, leading to inconsistent doping levels. Precise thermal control is required to keep the generation of active gases constant throughout the deposition window.

Making the Right Choice for Your Goal

To maximize the efficacy of this CVD configuration, align your process parameters with your specific synthesis targets:

- If your primary focus is Doping Homogeneity: Prioritize a stable, laminar carrier gas flow to ensure the iodine species are evenly distributed across the entire carbon substrate.

- If your primary focus is Atom Anchoring Efficiency: Calibrate the upstream temperature carefully to ensure the sublimation rate matches the density of defect sites available downstream.

By leveraging the physics of the tube furnace, you transform a simple heating process into a tool for precise atomic engineering.

Summary Table:

| Factor | Upstream Configuration Role | Impact on I-NC Quality |

|---|---|---|

| Thermal Gradient | Sublimation/Decomposition zone | Controls gas phase generation rate |

| Gas Dynamics | Carrier gas transport mechanism | Prevents back-diffusion & ensures flow |

| Mixing Zone | Homogenization of active gases | Eliminates doping hotspots/irregularities |

| Atomic Targeting | Controlled delivery to substrate | Facilitates precise anchoring at defect sites |

Elevate Your Material Engineering with KINTEK

Precision in Iodine-doped Nitrogen-Carbon (I-NC) synthesis requires more than just a setup—it requires absolute thermal and fluid control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Vacuum, and CVD systems designed to maintain the stable temperature gradients and laminar flow patterns critical for atomic-level doping.

Whether you need a standard solution or a customizable system tailored to your unique research needs, our lab high-temp furnaces provide the stability your materials demand.

Ready to optimize your CVD process? Contact KINTEK today to discuss your project and see how our expert systems can enhance your lab's efficiency.

Visual Guide

References

- Junjun Pei, Jinming Luo. Non-metallic iodine single-atom catalysts with optimized electronic structures for efficient Fenton-like reactions. DOI: 10.1038/s41467-025-56246-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- What are the key features of an alumina tube furnace? Achieve Precise High-Temp Processing

- Why is a high-temperature tube furnace required for the synthesis of Fe-N-C catalysts? Key for Atomic Engineering

- What environmental conditions does a vacuum tube furnace provide for sawdust biochar? Achieve Precise Pyrolysis Control

- What are the primary functions of a tube furnace for ZIF-derived materials? Optimize Carbonization & Porosity

- What is a high temperature tube furnace? Achieve Precise Heat and Atmosphere Control

- What role does a Drop Tube Furnace (DTF) play? Expert Insights into Industrial Combustion Simulation

- How does gas flow control in a tube furnace influence the quality of NMC811? Master Stable Calcination Environments