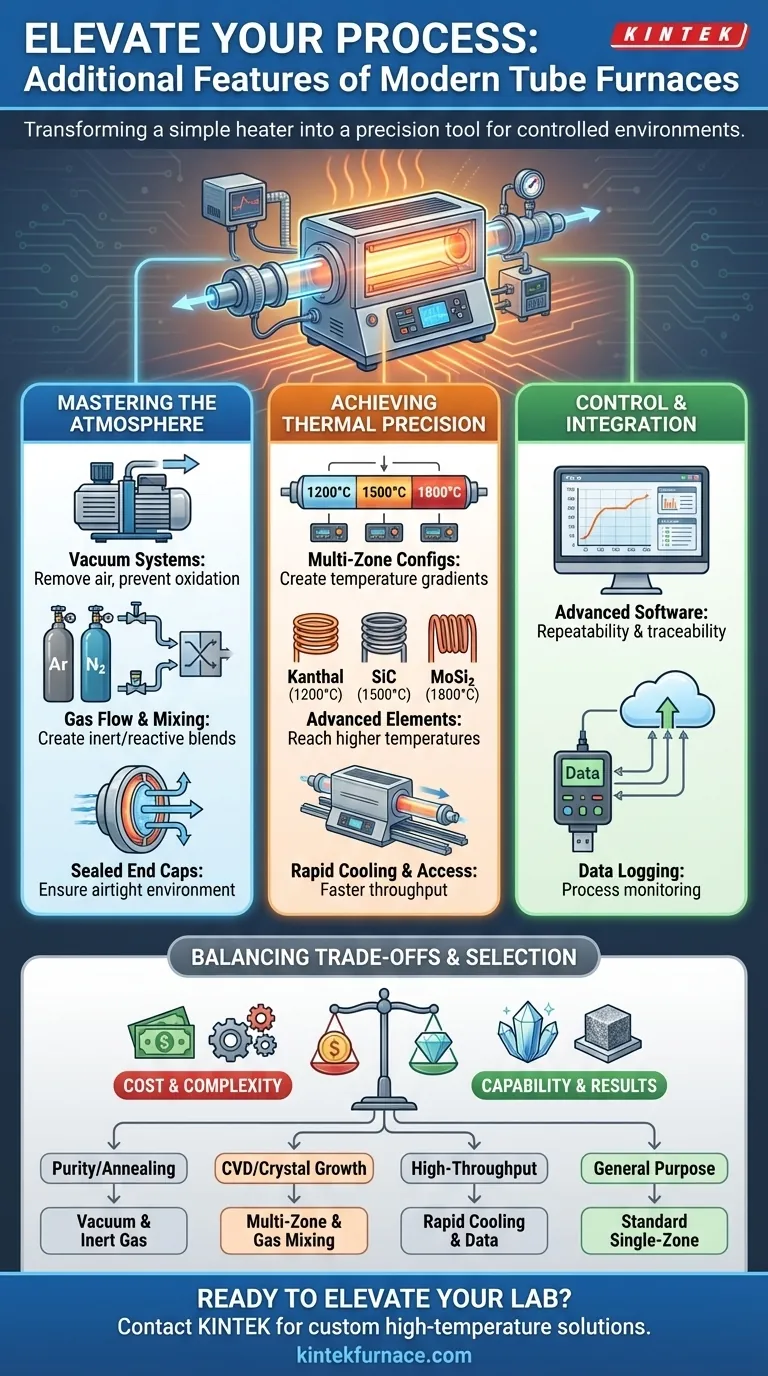

Beyond basic heating, a modern tube furnace can be transformed into a highly specialized instrument through a range of optional features. These enhancements are primarily designed to control the process atmosphere, create precise thermal profiles, and integrate sophisticated control and data logging. Key additions include vacuum systems, gas mixing capabilities, multi-zone heating configurations, and advanced software control.

A standard tube furnace provides heat. An advanced tube furnace provides a precisely controlled and repeatable environment. The additional features are not just accessories; they are tools that enable specific, demanding processes like chemical vapor deposition (CVD), material synthesis, and high-purity annealing.

Mastering the Process Environment: Atmosphere Control

The most critical enhancements for a tube furnace revolve around controlling the atmosphere inside the process tube. This is essential for preventing oxidation and enabling specific chemical reactions.

Vacuum Systems

A vacuum system is used to evacuate the ambient air—primarily oxygen and moisture—from the process tube before heating or introducing a specific gas. This is critical for working with oxygen-sensitive materials. High-end systems can achieve vacuum levels down to 10⁻⁵ torr, creating a near-perfectly clean environment.

Gas Flow and Inert Atmospheres

Once a vacuum is established, an inert gas like argon or nitrogen can be introduced to create a protective, oxygen-free atmosphere. This gas flow is managed by controllers to maintain a slight positive pressure, preventing any air from leaking back into the tube during operation.

Gas Mixing Systems

For advanced processes like CVD, simply flowing one gas is not enough. Gas mixing systems allow for the precise blending of multiple reactive or carrier gases. Systems like SIMGAS4 offer programmable control over gas ratios, enabling complex material deposition and synthesis protocols.

Sealed End Caps

None of the above is possible without effective end caps that create an airtight seal on the tube. These are often made of stainless steel and can include features like water-cooling jackets to protect the seals and gaskets during high-temperature operation.

Achieving Precision Thermal Profiles

Controlling the temperature profile along the length of the furnace is just as important as controlling the atmosphere for many applications.

Multi-Zone Configurations

While a standard furnace has a single heating zone, a multi-zone furnace has two, three, or more independently controlled heating sections. This allows the user to create a specific temperature gradient along the tube or to create a much longer, exceptionally uniform hot zone.

Advanced Heating Elements

The maximum achievable temperature of a furnace is determined by its heating elements. Furnaces are equipped with different materials to meet specific needs:

- Kanthal (A-1): Typically for temperatures up to 1200°C.

- Silicon Carbide (SiC): Used for temperatures up to 1500°C.

- Molybdenum Disilicide (MoSi₂): Required for the highest temperatures, reaching up to 1800°C.

Rapid Cooling and Access

Designs that incorporate a sliding or splitting mechanism allow the furnace body to be moved away from the process tube. This enables rapid cooling of the sample and provides easy access for loading and unloading, significantly improving throughput and user safety.

Understanding the Trade-offs and Limitations

While advanced features add immense capability, they also introduce complexity and cost. It's crucial to weigh the benefits against the practical requirements.

Cost vs. Capability

Every feature, from a vacuum pump to a multi-zone controller, adds significant cost. Over-specifying a furnace with capabilities that will never be used is a common and expensive mistake. A thorough analysis of your process requirements is essential.

Operational Complexity

A simple single-zone furnace is straightforward to operate. A multi-zone furnace with an integrated vacuum and gas mixing system requires significant operator training to use correctly and safely. The setup, programming, and leak-checking procedures are more involved.

Maintenance and Consumables

Advanced systems require more maintenance. Vacuum pumps need oil changes, seals and gaskets on end caps wear out and need replacement, and mass flow controllers may require periodic recalibration. These ongoing operational costs should be factored into the initial purchase decision.

Selecting the Right Features for Your Application

Choose features based on the specific outcome you need to achieve. The goal is to build an instrument that perfectly matches your process.

- If your primary focus is material purity and simple annealing: Prioritize a high-quality vacuum system and an inert gas flow controller.

- If your primary focus is crystal growth or Chemical Vapor Deposition (CVD): A multi-zone furnace with a sophisticated gas mixing system is essential for controlling gradients and reactant delivery.

- If your primary focus is high-throughput testing or quality control: Look for features like a sliding design for rapid cooling and advanced data acquisition software for process traceability.

- If your primary focus is general-purpose heating on a budget: A standard single-zone furnace with a reliable digital controller is a robust and cost-effective solution.

By matching these advanced features to your specific scientific or industrial goal, you transform the tube furnace from a simple heater into a precision processing tool.

Summary Table:

| Feature Category | Key Options | Primary Benefits |

|---|---|---|

| Atmosphere Control | Vacuum systems, Gas flow controllers, Gas mixing systems, Sealed end caps | Prevents oxidation, enables specific reactions, ensures purity |

| Thermal Precision | Multi-zone configurations, Advanced heating elements, Rapid cooling mechanisms | Creates gradients, uniform heating, faster throughput |

| Control & Integration | Advanced software, Data logging | Repeatability, traceability, ease of operation |

Ready to elevate your laboratory's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in materials science, chemistry, or industrial research, we can help you achieve superior process control and efficiency. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency