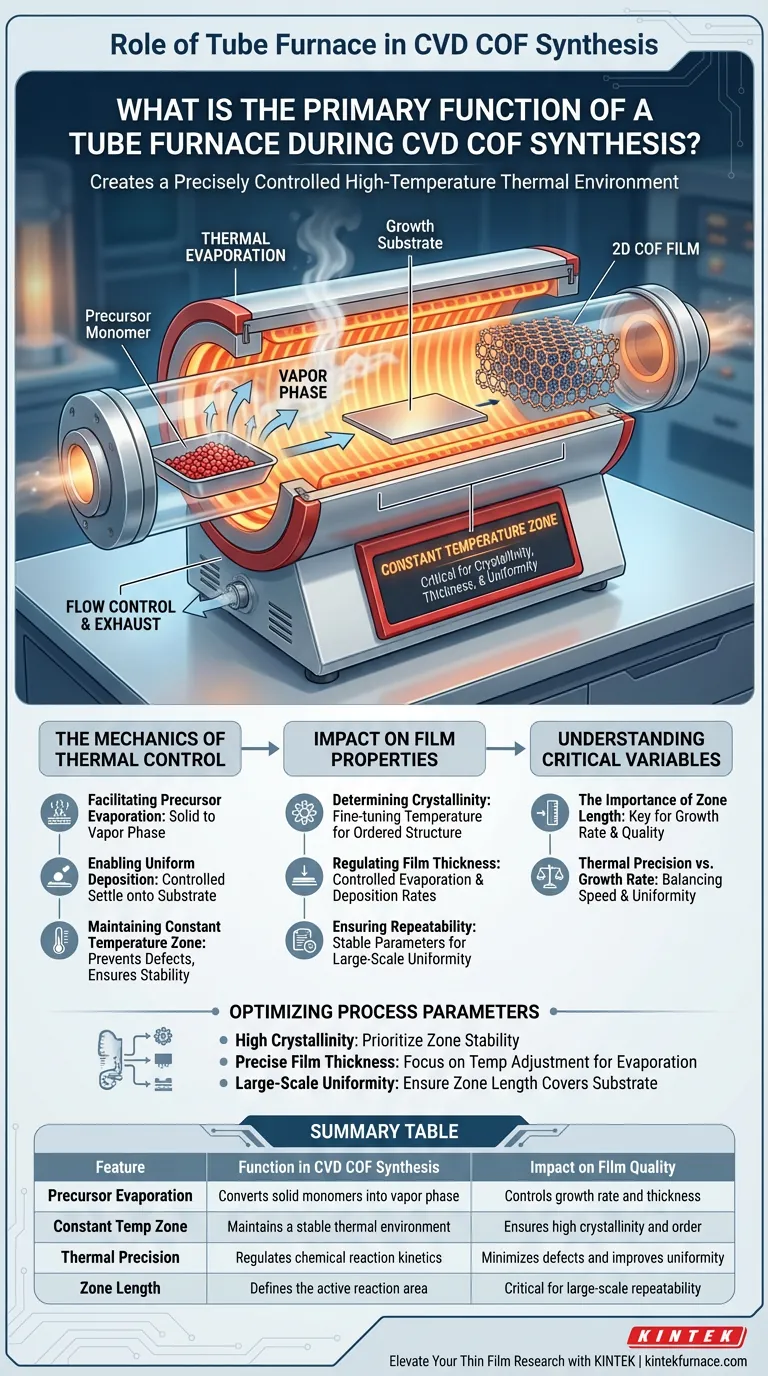

The primary function of a tube furnace during the Chemical Vapor Deposition (CVD) synthesis of 2D Covalent Organic Framework (COF) films is to create a precisely controlled high-temperature thermal environment. This environment is essential to thermally evaporate precursor monomers and ensure they deposit uniformly onto a growth substrate. By strictly regulating this thermal profile, the furnace facilitates the chemical reactions required to form high-quality films.

Core Takeaway The tube furnace acts as the engine of the CVD process, transforming solid precursors into gas through thermal evaporation. Its value lies in its ability to maintain a specific "constant temperature zone," which directly dictates the crystallinity, thickness, and uniformity of the final COF film.

The Mechanics of Thermal Control

Facilitating Precursor Evaporation

The initial role of the tube furnace is to provide the energy required to change the state of the raw materials. It heats the precursor monomers to a specific point where they undergo thermal evaporation, transitioning from a solid phase into a vapor phase.

Enabling Uniform Deposition

Once the precursors are in a vapor state, the furnace maintains the thermal conditions necessary for them to settle onto the growth substrate. This controlled environment ensures that the deposition process occurs evenly across the substrate surface.

Maintaining the Constant Temperature Zone

The furnace creates a "constant temperature zone" within the reaction tube. This stability is critical because fluctuations in temperature across the reaction area can lead to defects or uneven film growth.

Impact on Film Properties

Determining Crystallinity

The quality of the internal structure of the COF film—its crystallinity—is heavily dependent on thermal precision. By fine-tuning the furnace temperature, operators can ensure the molecular framework forms a highly ordered structure rather than an amorphous one.

Regulating Film Thickness

The thickness of the 2D COF film is not accidental; it is a result of controlled evaporation and deposition rates. Adjusting the heating temperature allows for precise management of how much material is deposited over a set period.

Ensuring Repeatability

For large-scale preparation, the ability to reproduce results is vital. The tube furnace provides the stable parameters needed to achieve high uniformity and repeatability, ensuring that the same process yields the same high-quality film every time.

Understanding the Critical Variables

The Importance of Zone Length

It is not enough to simply reach a high temperature; the length of the constant temperature zone matters. The primary reference highlights that adjusting this length is a key variable in controlling the growth rate and quality of the film.

Thermal Precision vs. Growth Rate

There is a direct correlation between the heating temperature and the rate of film growth. However, aggressive heating to speed up growth can compromise uniformity, meaning operators must balance speed with the need for a stable thermal environment.

Optimizing Process Parameters

To achieve the best results in 2D COF film synthesis, you must align the furnace settings with your specific material goals.

- If your primary focus is high crystallinity: Prioritize the stability of the constant temperature zone to ensure an ordered molecular structure.

- If your primary focus is precise film thickness: Focus on the fine adjustment of the heating temperature to strictly regulate the evaporation rate of the monomers.

- If your primary focus is large-scale uniformity: Ensure the length of the constant temperature zone covers the entire substrate area to prevent edge defects.

Ultimately, the tube furnace is not just a heating element; it is the control instrument that translates chemical potential into structural reality.

Summary Table:

| Feature | Function in CVD COF Synthesis | Impact on Film Quality |

|---|---|---|

| Precursor Evaporation | Converts solid monomers into vapor phase | Controls growth rate and thickness |

| Constant Temp Zone | Maintains a stable thermal environment | Ensures high crystallinity and order |

| Thermal Precision | Regulates chemical reaction kinetics | Minimizes defects and improves uniformity |

| Zone Length | Defines the active reaction area | Critical for large-scale repeatability |

Elevate Your Thin Film Research with KINTEK

Maximize the precision of your 2D Covalent Organic Framework (COF) synthesis with KINTEK’s high-performance tube furnaces. Backed by expert R&D and world-class manufacturing, we provide advanced Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for your laboratory's most demanding high-temperature applications.

Whether you need custom temperature zones or specialized gas flow controls, our systems are fully customizable to your unique research needs. Contact us today to optimize your CVD process and see how KINTEK can deliver the thermal stability and repeatability your materials science requires.

Visual Guide

References

- Jin Hyuk Cho, Soo Young Kim. Advancements in two-dimensional covalent organic framework nanosheets for electrocatalytic energy conversion: current and future prospects. DOI: 10.20517/energymater.2023.72

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does a high-temperature tube furnace contribute to the synthesis of nitrogen-doped graphene? Boost Your Lab Results

- What is the core function of a tube furnace in EN-LCNF synthesis? Unlock Precision Nanosheet Frameworks

- How do laboratory-scale Tube Furnaces facilitate coal gasification? Precise Simulation for Industrial Success

- Why is an atmosphere-controlled tube furnace required for NC substrate preparation? Essential for carbonization.

- What role does a tube annealing furnace play in the preparation of nanoporous NiPt catalysts? Vital Catalyst Activation

- How does the working temperature range affect the choice of a vertical tube furnace? Optimize Your Lab's Performance and Budget

- How does the sealing mechanism in Quartz Tube Furnaces differ from traditional systems? Discover Advanced Sealing for Reliable Results

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety