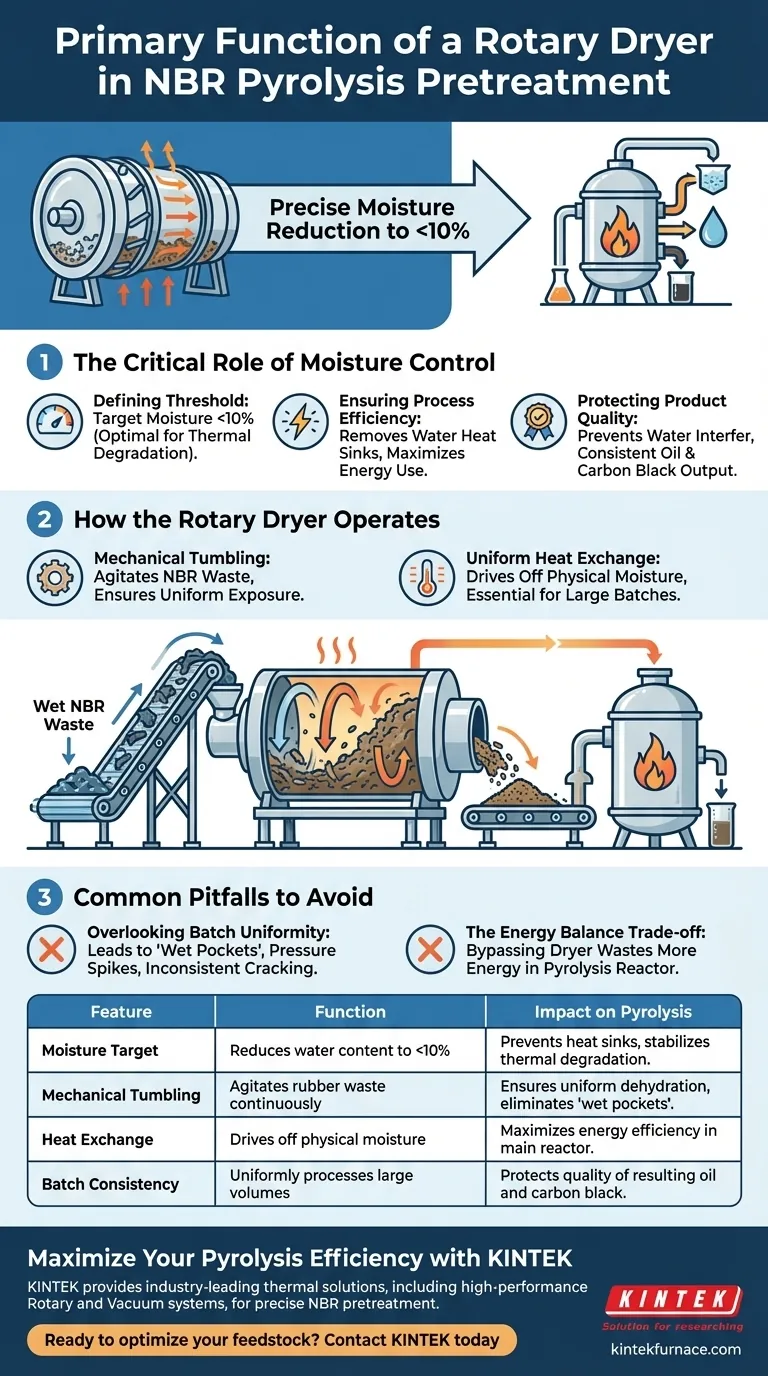

The primary function of a rotary dryer in the NBR pyrolysis workflow is precise moisture reduction. Specifically, it is designed to lower the water content of raw Nitrile Butadiene Rubber waste to a level below 10%. This is achieved through a continuous process of mechanical tumbling and heat exchange to ensure uniform dehydration across large batches.

Effective pyrolysis requires a stable, dry feedstock. Reducing moisture content to less than 10% is the critical baseline for ensuring thermal efficiency and maintaining the high quality of your final pyrolysis products.

The Critical Role of Moisture Control

Defining the Threshold

The specific goal of the pretreatment phase is to bring the moisture content of the NBR waste down to a strict target.

For optimal pyrolysis performance, this level must be maintained below 10%. Exceeding this threshold introduces variables that can destabilize the subsequent thermal degradation process.

Ensuring Process Efficiency

Water content acts as a significant heat sink in a pyrolysis reactor.

By removing this moisture beforehand, the rotary dryer ensures that thermal energy in the main reactor is utilized for breaking down chemical bonds in the rubber, rather than evaporating excess water. This maximizes the energy efficiency of the entire system.

Protecting Product Quality

The presence of excess moisture does not just affect energy consumption; it impacts the chemical composition of the output.

Proper dehydration prevents water from interfering with the reaction, ensuring the resulting oil and carbon black maintain consistent quality standards.

How the Rotary Dryer Operates

Mechanical Tumbling

To achieve the 10% target, the dryer cannot simply apply heat to the surface of a pile of waste.

The rotary dryer utilizes mechanical tumbling to agitate the NBR waste. This ensures that every piece of rubber is exposed to the drying environment, preventing "wet pockets" deep within the batch.

Uniform Heat Exchange

Tumbling is combined with a heat exchange mechanism to drive off physical moisture.

This combination allows for the uniform dehydration of large batches, which is essential for industrial-scale operations where consistency is key.

Common Pitfalls to Avoid

Overlooking Batch Uniformity

A common error in pretreatment is assuming that an average moisture reading applies to the whole batch.

If the dryer does not tumble the material effectively, you may have an average moisture of 10%, but specific pockets of high humidity. These wet spots can cause pressure spikes or inconsistent cracking during pyrolysis.

The Energy Balance Trade-off

Running a rotary dryer consumes energy, representing an upfront operational cost.

However, attempting to bypass this step to save energy is a false economy. The energy required to boil off water inside the pyrolysis reactor is often significantly higher and more disruptive than the energy used by the rotary dryer during pretreatment.

Making the Right Choice for Your Goal

To optimize your NBR pyrolysis project, align your drying parameters with your specific operational targets:

- If your primary focus is Process Efficiency: Ensure your dryer is calibrated to consistently hit the <10% moisture mark to prevent energy waste in the main reactor.

- If your primary focus is Product Consistency: Prioritize the mechanical tumbling aspect of the dryer to guarantee that the feedstock is uniform before reaction.

A well-calibrated rotary dryer is not just a preparation tool; it is the foundation of a stable and profitable pyrolysis operation.

Summary Table:

| Feature | Function in NBR Pretreatment | Impact on Pyrolysis |

|---|---|---|

| Moisture Target | Reduces water content to <10% | Prevents heat sinks and stabilizes thermal degradation |

| Mechanical Tumbling | Agitates rubber waste continuously | Ensures uniform dehydration and eliminates 'wet pockets' |

| Heat Exchange | Drives off physical moisture | Maximizes energy efficiency in the main reactor |

| Batch Consistency | Uniformly processes large volumes | Protects the quality of resulting oil and carbon black |

Maximize Your Pyrolysis Efficiency with KINTEK

Don't let moisture compromise your chemical output or drain your energy resources. KINTEK provides industry-leading thermal solutions, including high-performance Rotary and Vacuum systems, engineered for the precise pretreatment of materials like Nitrile Butadiene Rubber.

Backed by expert R&D and world-class manufacturing, our lab and industrial furnaces are fully customizable to meet your unique moisture reduction and heat treatment needs. Ensure a stable and profitable operation by choosing equipment that delivers consistency.

Ready to optimize your feedstock? Contact KINTEK today to discuss your custom pyrolysis solution!

Visual Guide

References

- Kasun Pathiraja, Kaveenga Rasika Koswattage. Sustainable Management of Nitrile Butadiene Rubber Waste Through Pyrolysis. DOI: 10.3390/su17030846

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What materials are rotary tube furnaces typically constructed from? Choose the Right Tube for Your Process

- Why is high-precision temperature control essential for studying reduction kinetics in suspension reduction furnaces?

- How does the rotating design of the rotary tube sintering furnace improve heating uniformity? Achieve Consistent Results

- What are the key technical specifications of a Rotary Tube Tilt Furnace? Optimize Your Thermal Processing

- What are the main advantages of rotary furnaces in industrial applications? Boost Efficiency and Uniformity

- How do indirect-fired rotary kilns contribute to metallurgical processes? Unlock High-Purity Material Processing

- What are the primary heat treatment processes performed using rotary furnaces? Achieve Uniform Bulk Material Processing

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing