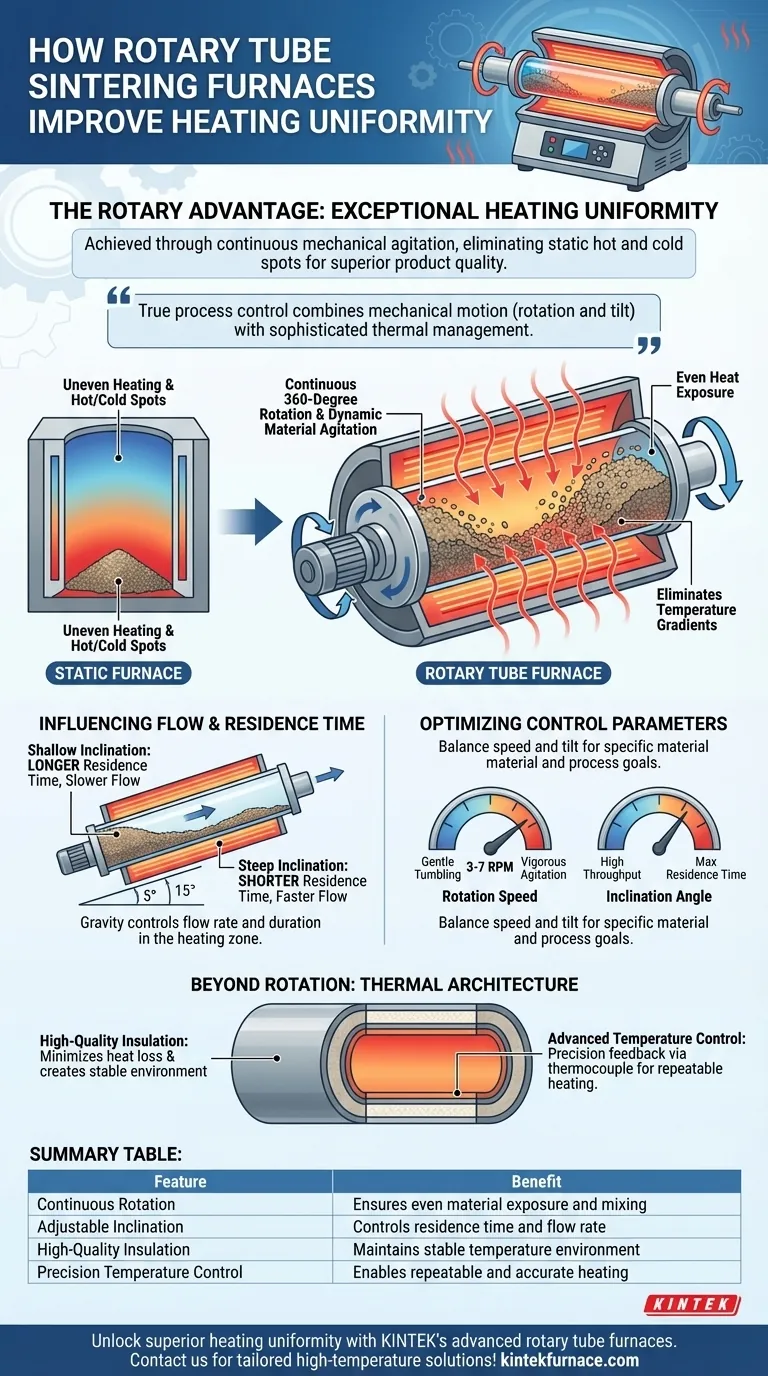

The primary advantage of a rotary tube sintering furnace is its ability to achieve exceptional heating uniformity through continuous mechanical agitation. As the furnace tube rotates, the material inside constantly tumbles and mixes, ensuring every particle is evenly exposed to the heat source. This dynamic process eliminates the static hot and cold spots common in stationary furnaces, preventing local overheating or incomplete reactions and dramatically improving final product quality.

While the rotating tube is the most visible feature for ensuring uniformity, true process control comes from a combination of mechanical motion (rotation and tilt) and sophisticated thermal management, including high-quality insulation and precision temperature control.

The Core Mechanism: Dynamic Material Agitation

The fundamental design principle of a rotary tube furnace is to keep the material in motion throughout the entire heating cycle. This contrasts sharply with static furnaces where material at the bottom and edges receives heat differently than material in the center.

Continuous 360-Degree Rotation

A motor drives the central furnace tube, causing it to rotate continuously. This action forces the powder or granular material inside to cascade, flip, and mix.

This constant tumbling is the key to uniform heating. It prevents any single portion of the material from remaining in one position, ensuring all surfaces are cyclically exposed to the radiant heat from the furnace walls.

Eliminating Hot and Cold Spots

In a static furnace, material touching the tube floor gets hotter, while the top layer remains cooler. This temperature gradient leads to uneven sintering, incomplete reactions, or thermal damage.

By keeping the material in motion, the rotary design averages out these temperature differences. This prevents local overheating and ensures the entire batch experiences a near-identical thermal history, which is critical for process consistency.

Influencing Flow and Residence Time

Beyond simple rotation, advanced rotary furnaces add another layer of control through tilting. This feature is crucial for managing how long the material spends in the heating zone.

The Role of Inclination (Tilting)

Many rotary tube furnaces can be tilted at a specific angle. This inclination uses gravity to control the flow rate of material through the tube in a continuous or semi-continuous process.

A steeper angle results in a faster transit time, while a shallower angle increases the time the material spends inside the furnace.

Optimizing Residence Time

Residence time—the duration the material is exposed to the target temperature—is a critical process parameter. By adjusting the furnace's inclination angle in coordination with its rotation speed, you can precisely control this variable.

This control ensures that the material is heated for the exact duration required for the desired chemical or physical transformation to complete.

Understanding the Trade-offs and Control Parameters

Achieving perfect uniformity requires balancing several interconnected variables. Simply turning on the rotation is not enough; the settings must be optimized for your specific material and process goals.

Adjusting Rotation Speed

The speed of rotation, typically between 3 and 7 RPM, affects the intensity of the mixing. A slower speed provides gentle tumbling, while a faster speed creates more vigorous agitation.

The ideal speed depends on the material's characteristics. You must find a balance that ensures good mixing without causing excessive particle degradation or dust generation.

Setting the Inclination Angle

The tilt angle directly dictates material throughput versus residence time. A steep angle prioritizes high throughput but may not allow enough time for reactions to complete. A shallow angle maximizes residence time but slows down the process.

This parameter must be carefully tuned based on experimental results to achieve the desired outcome efficiently.

Beyond Rotation: The Furnace's Thermal Architecture

The mechanical design is only half of the equation. The furnace's underlying thermal construction plays a vital role in creating a stable and uniform environment.

High-Quality Insulation

Modern furnaces use multi-layer, high-purity insulation materials. This minimizes heat loss and, more importantly, ensures that the temperature field around the rotating tube is as uniform as possible.

Advanced Temperature Control

A high-precision temperature controller, using feedback from a thermocouple, is the brain of the system. It constantly adjusts power to the heating elements to maintain the set temperature profile with minimal deviation.

This intelligent control ensures the process is not only uniform but also highly repeatable from one batch to the next.

Making the Right Choice for Your Process

To achieve optimal uniformity, you must consider how each control parameter interacts to meet your specific goal.

- If your primary focus is a complete chemical reaction: Prioritize a longer residence time by using a shallower inclination angle, ensuring the material is exposed to heat long enough for full conversion.

- If your primary focus is high throughput: Utilize a steeper inclination angle for faster material flow, but compensate with a precise temperature profile and sufficient rotation speed to complete the process in the shorter time frame.

- If your primary focus is consistent product quality: Conduct trials to find the ideal balance between rotation speed and tube angle that delivers the most uniform results for your specific material.

By mastering these interconnected variables, you can leverage the rotary tube furnace to achieve highly consistent and reproducible results for your application.

Summary Table:

| Feature | Benefit |

|---|---|

| Continuous Rotation | Ensures even material exposure and mixing |

| Adjustable Inclination | Controls residence time and flow rate |

| High-Quality Insulation | Maintains stable temperature environment |

| Precision Temperature Control | Enables repeatable and accurate heating |

Unlock superior heating uniformity for your lab with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our furnaces can optimize your sintering processes and deliver consistent, high-quality results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How are rotary tube furnaces utilized in industrial production? Boost Efficiency with Uniform Thermal Processing

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the key advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency for Your Materials

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results