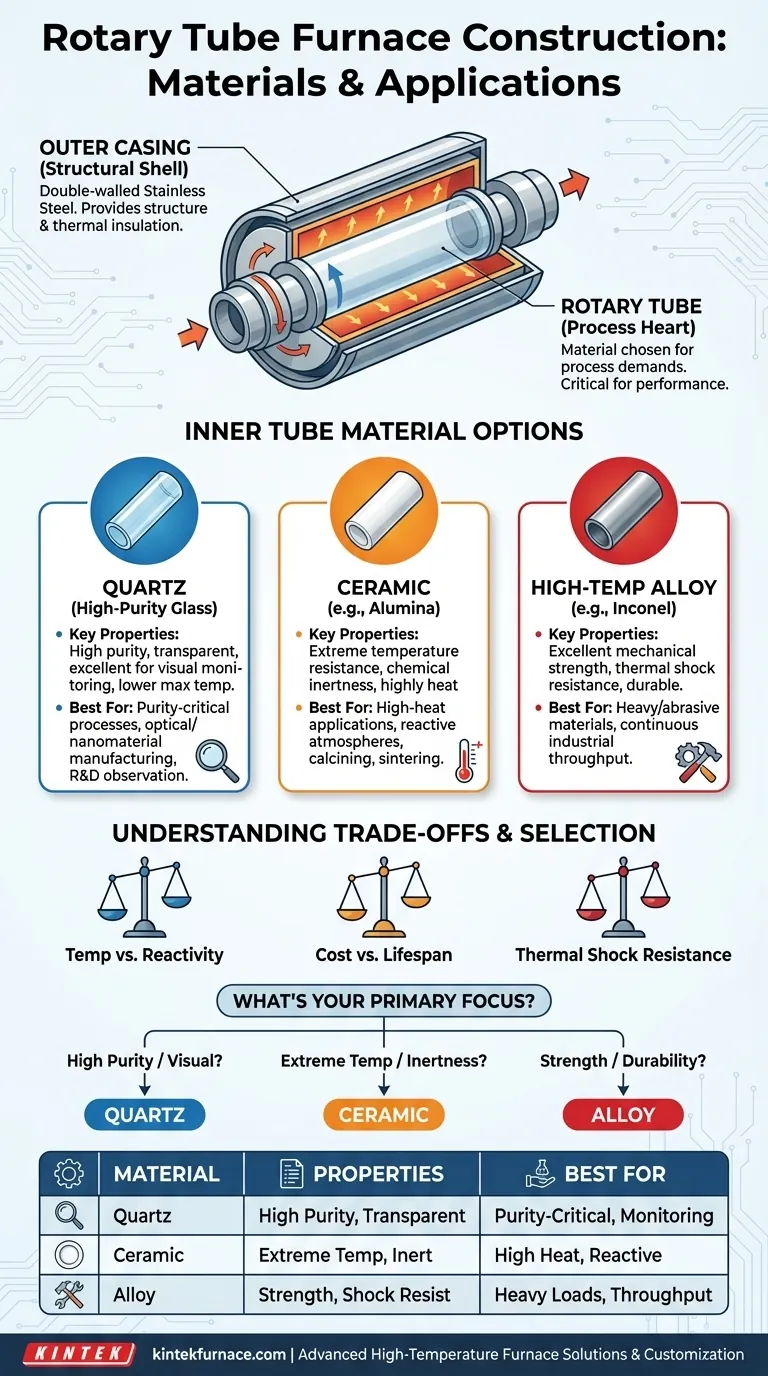

At their core, rotary tube furnaces are built from two primary material groups. The outer furnace body is almost always constructed from double-walled stainless steel for structural integrity and insulation. The critical inner rotary tube, however, is made from a material chosen specifically for the process: typically quartz, ceramic, or a high-temperature metal alloy.

The choice of material for the inner rotary tube is the single most important factor determining a furnace's performance. This decision is not about finding the "best" material overall, but about precisely matching the tube's properties to the temperature, chemical reactivity, and purity requirements of your specific application.

The Anatomy of a Rotary Tube Furnace

A rotary tube furnace is not a single entity but a system of components. Understanding the role of each part clarifies why different materials are used.

The Outer Casing: The Structural Shell

The external body of the furnace is typically made from double-walled stainless steel. This construction provides the durable frame that houses the heating elements and insulation.

This design creates an air gap between the inner and outer walls, which significantly improves thermal insulation. It keeps the exterior cool and safe while ensuring heat is directed uniformly toward the central rotary tube.

The Rotary Tube: The Process Heart

This is the rotating cylinder where your material is actually processed. The material for this tube is chosen based on the demands of the thermal treatment.

The selection of quartz, ceramic, or a high-temperature alloy directly dictates the furnace's maximum temperature, its resistance to chemical reactions, and the purity of the final product.

Why the Rotary Tube Material is Critical

The function of the furnace—whether for calcining, material synthesis, or oxidation—imposes different stresses on the tube. The material must be able to withstand the thermal and chemical environment of your process.

Quartz Tubes for Purity and Observation

Quartz is a form of high-purity glass. It is often chosen when preventing contamination is the highest priority, such as in the manufacturing of optical materials or nanomaterials.

Its transparency also allows for direct visual monitoring of the process, which can be invaluable for research and development applications. However, quartz generally has a lower maximum operating temperature compared to ceramics.

Ceramic Tubes for Extreme Temperatures

When a process requires extremely high temperatures, ceramic tubes (often made of high-purity alumina) are the standard choice.

Ceramics are highly resistant to heat and are chemically inert in most atmospheres, making them ideal for aggressive processes like calcining refractory materials or sintering metal powders at temperatures that would compromise quartz or most alloys.

High-Temperature Alloy Tubes for Durability

Tubes made from high-temperature metal alloys (like Inconel) offer excellent mechanical strength and resistance to thermal shock.

Their durability makes them suitable for processing heavy or abrasive materials, such as iron ore pellets or cement clinker, in a continuous throughput environment. They also provide excellent thermal conductivity for uniform heating.

Understanding the Trade-offs

Selecting a furnace involves balancing competing factors. An ideal material for one goal may be a poor choice for another.

Temperature vs. Reactivity

A material's ability to withstand high temperatures does not guarantee it will work for your process. Some metal alloys, while strong at high heat, may react with your process materials or gases, introducing impurities. A chemically inert ceramic tube avoids this but may have different thermal properties.

Cost vs. Lifespan

High-performance materials come at a premium. An advanced ceramic or a specialized alloy tube will be more expensive upfront than a standard quartz tube. This cost must be weighed against the potential for longer service life, especially under harsh chemical or thermal conditions.

Thermal Shock Resistance

Materials respond differently to rapid temperature changes. Quartz, for example, can be susceptible to cracking (thermal shock) if heated or cooled too quickly. Process parameters must be designed around the material's physical limitations to prevent damage and ensure a long lifespan.

Selecting the Right Material for Your Process

Your specific goal dictates the correct material choice. To make an informed decision, prioritize what matters most for your application.

- If your primary focus is high-purity processing or visual monitoring: A quartz tube is the most logical choice, provided your temperature requirements are within its operational limits.

- If your primary focus is achieving the highest possible temperatures or chemical inertness: A ceramic tube, such as one made from alumina, is necessary for extreme heat and reactive environments.

- If your primary focus is mechanical strength for heavy or abrasive materials: A high-temperature metal alloy tube provides the durability and thermal conductivity needed for industrial-scale throughput.

By understanding how each material serves the furnace's function, you can select a system that is perfectly suited to your technical requirements.

Summary Table:

| Material Type | Key Properties | Best For |

|---|---|---|

| Quartz | High purity, transparent, lower temperature | Purity-critical processes, visual monitoring |

| Ceramic | Extreme temperature resistance, chemical inertness | High-heat applications, reactive atmospheres |

| High-Temperature Alloy | Mechanical strength, thermal shock resistance | Heavy/abrasive materials, industrial throughput |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need quartz for purity, ceramic for extreme heat, or alloys for durability, we can tailor a solution to enhance your process efficiency and results. Contact us today to discuss your specific needs and discover how KINTEK can support your laboratory goals!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What is the role of rotary tube furnaces in the energy sector? Boost Efficiency in Biomass and Battery Material Processing

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing

- How do rotary tube furnaces enhance efficiency in materials processing? Boost Throughput and Quality

- What makes rotary tube furnaces user-friendly? Achieve Superior Process Uniformity and Efficiency