At their core, rotary furnaces excel due to their unique ability to combine continuous material processing with exceptionally uniform heat transfer. This is achieved by tumbling the material within a rotating, inclined cylinder, ensuring every particle is consistently exposed to the heat source. This dynamic process makes them a superior choice for high-volume industrial applications where product consistency is paramount.

The true advantage of a rotary furnace is not just heating, but creating a dynamic processing environment. Its constant rotation ensures uniform temperature while simultaneously enhancing gas-solid reactions, making it an indispensable tool for producing consistent, high-quality materials at an industrial scale.

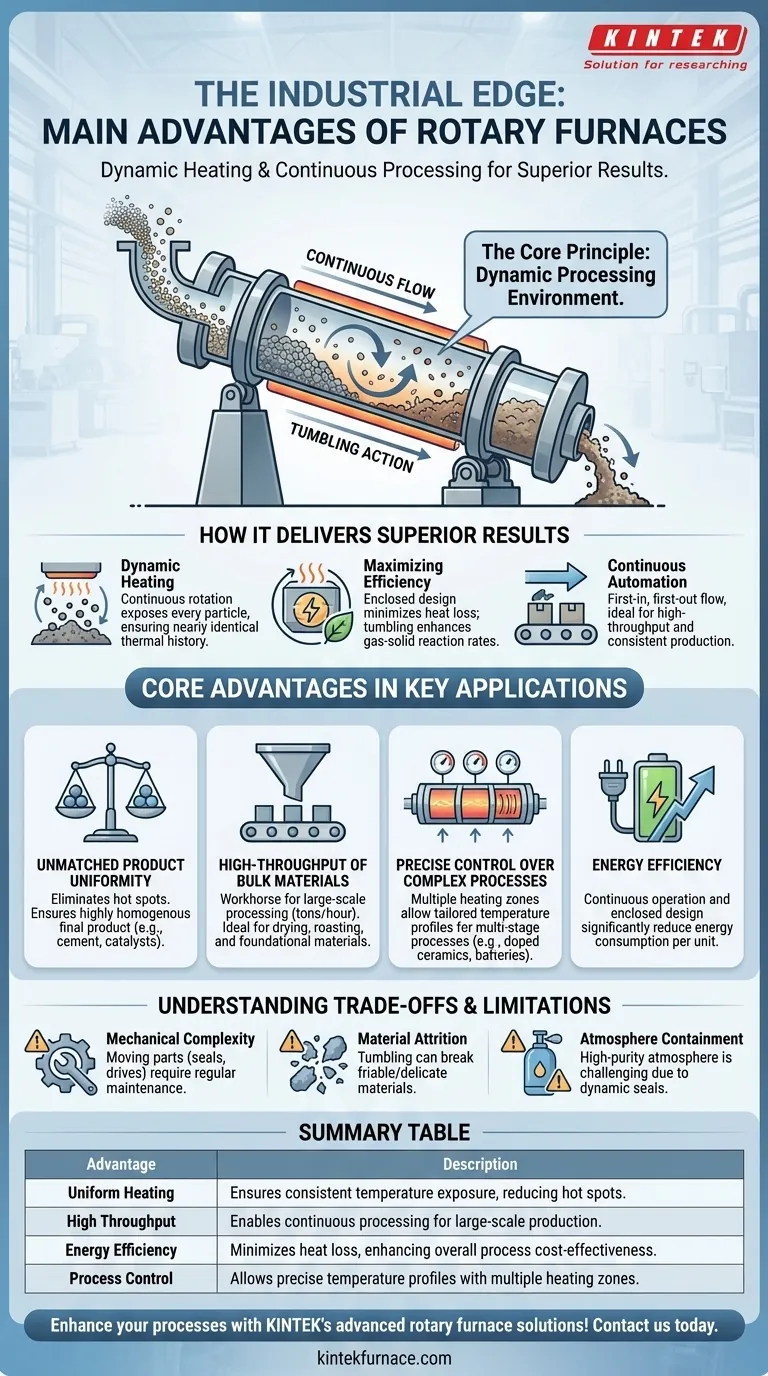

How a Rotary Furnace Delivers Superior Results

The design of a rotary furnace is simple in principle but powerful in execution. It consists of a long, cylindrical tube or barrel, slightly inclined, that rotates slowly. This fundamental design is the source of its primary benefits.

The Principle of Dynamic Heating

Material fed into the higher end of the furnace travels downward through a combination of rotation and gravity. This constant tumbling action is the key.

Unlike a static furnace where material at the bottom may be shielded, the rotation continuously exposes new surfaces to the indirect heat from the furnace walls. This guarantees that every particle experiences a nearly identical thermal history.

Maximizing Energy and Process Efficiency

The enclosed, continuous nature of a rotary furnace is inherently energy-efficient. Heat loss is minimized because there is no need to open the furnace for batch loading and unloading.

Furthermore, the tumbling action significantly increases the surface area of the material exposed to the process atmosphere. This enhances the rate of gas diffusion, making reactions like oxidation, roasting, and chemical synthesis far more efficient.

Enabling Continuous, Automated Processing

Rotary furnaces are ideal for high-throughput production lines. The "first-in, first-out" flow of material allows for a predictable, continuous output that can be integrated directly into a larger manufacturing process.

This design is particularly effective for processing powders, granules, and other bulk solids, as it minimizes the need for manual material handling and ensures a consistent production rate.

Core Advantages in Key Applications

These design principles translate into tangible benefits across a wide range of industries, from mineral processing to advanced materials manufacturing.

Unmatched Product Uniformity

The primary benefit is consistency. By eliminating hot spots and ensuring uniform heat exposure, rotary furnaces produce a highly homogenous final product.

This is critical in applications like manufacturing cement clinker, calcining alumina, producing iron ore pellets, or synthesizing catalysts, where slight temperature variations can drastically alter material properties and performance.

High-Throughput of Bulk Materials

The ability to operate continuously makes rotary furnaces the go-to solution for large-scale thermal processing. They are workhorses in industries that need to process tons of material per hour.

Applications include drying bulk chemicals, roasting ores, and preparing foundational materials like vermiculite.

Precise Control Over Complex Processes

Modern rotary furnaces can be designed with multiple, independently controlled heating zones. This allows for a precisely tailored temperature profile along the length of the furnace.

This level of control is essential for complex, multi-stage processes such as creating doped ceramics, performing specific phase transitions in materials, or manufacturing components for lithium batteries.

Understanding the Trade-offs and Limitations

While powerful, a rotary furnace is not a universal solution. Understanding its limitations is crucial for making a sound technical decision.

Mechanical Complexity and Maintenance

The rotating design introduces moving parts, including drive systems, support rollers, and, most critically, seals at the inlet and outlet. These components require regular maintenance and can be points of failure not present in simpler static furnaces.

Potential for Material Attrition

The tumbling action that provides such uniform heating can also be a drawback. Friable or delicate materials can be broken down into smaller particles or dust, which may be undesirable for the final product.

Process Atmosphere Containment

While the enclosed system is efficient, achieving a perfectly controlled, high-purity inert or reactive atmosphere can be more challenging than in a sealed batch furnace due to the dynamic seals at either end of the rotating tube.

Making the Right Choice for Your Application

Selecting the correct thermal technology depends entirely on your primary processing goal.

- If your primary focus is high-volume production of bulk materials: The continuous processing and automation capabilities of a rotary furnace are unmatched for applications like cement, minerals, and basic chemicals.

- If your primary focus is achieving perfect product consistency: The dynamic heating mechanism is ideal for sensitive chemical reactions or material synthesis where uniform temperature is non-negotiable.

- If your primary focus is processing fragile crystals or delicate parts: You must carefully evaluate the potential for material attrition and consider alternative technologies like a static bed or belt furnace.

By understanding its core principles of dynamic heat transfer and continuous flow, you can determine if a rotary furnace is the optimal tool for achieving both scale and precision in your process.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Heating | Ensures consistent temperature exposure for all particles, reducing hot spots and improving product quality. |

| High Throughput | Enables continuous processing of bulk materials like powders and granules, ideal for large-scale production. |

| Energy Efficiency | Minimizes heat loss with enclosed design, enhancing overall process efficiency and reducing costs. |

| Process Control | Allows precise temperature profiles with multiple heating zones for complex reactions and material synthesis. |

Enhance your industrial processes with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by deep customization to meet unique experimental requirements. Whether you're in mineral processing, materials synthesis, or high-volume production, KINTEK delivers reliable, efficient solutions for superior results. Contact us today to discuss how we can optimize your thermal processing!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules