In metallurgy, indirect-fired rotary kilns are essential for high-purity thermal processing. They create a highly controlled environment to induce specific chemical and physical changes in materials without the risk of contamination from combustion gases. This makes them indispensable for processes like calcination, roasting, and agglomerating sensitive ores, concentrates, and recycled metals where final product quality is paramount.

The core value of an indirect-fired kiln lies in its design: it completely isolates the process material from the heat source. This separation provides unparalleled control over the processing atmosphere, enabling high-purity results that are impossible to achieve in direct-fired systems, albeit at a higher operational cost.

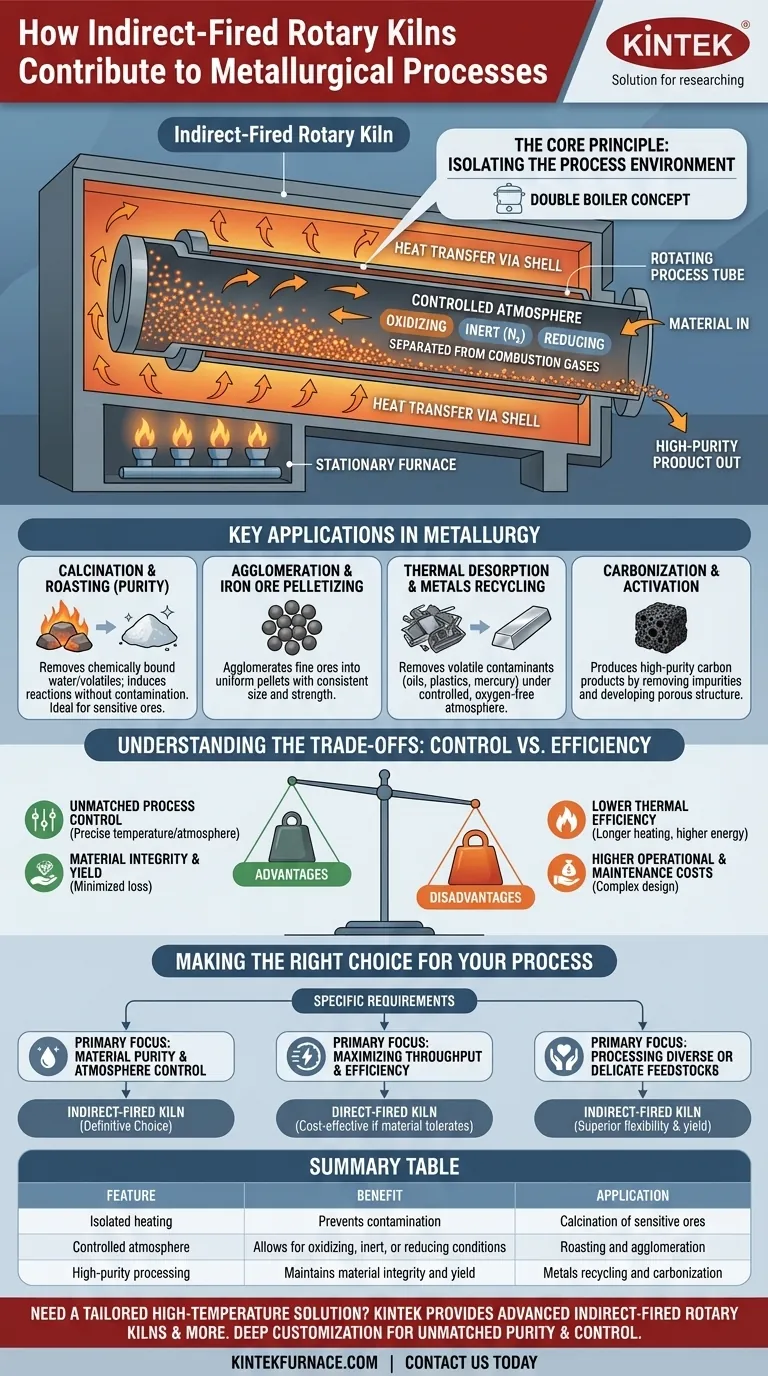

The Core Principle: Isolating the Process Environment

The unique capabilities of an indirect-fired kiln stem directly from its fundamental design, which prioritizes control and purity above all else.

The Double Boiler Concept

Think of an indirect kiln like a double boiler in a kitchen. Instead of applying direct flame to a delicate material like chocolate, you heat a surrounding medium (water) to provide gentle, uniform heat.

An indirect kiln works the same way. The rotating process tube containing the material is enclosed within a larger, stationary furnace. Burners heat the furnace, and that heat is transferred through the shell of the rotating tube to the material inside.

Material and Atmosphere Separation

This design is the key. The combustion gases from the burners never come into contact with the process material.

This separation allows for a completely independent and controlled atmosphere inside the kiln. The internal environment can be oxidizing, inert (using nitrogen, for example), or reducing, depending entirely on the specific metallurgical reaction required.

Key Applications in Metallurgy

This precise control makes indirect kilns uniquely suited for several critical metallurgical processes where product integrity is non-negotiable.

Calcination and Roasting for Purity

Calcination uses heat to remove chemically bound water or volatiles, while roasting induces specific chemical reactions. In an indirect kiln, these processes can occur without introducing impurities from fuel combustion.

This is critical when processing materials like bauxite or other sensitive mineral ores where even trace contaminants can compromise the final metal's quality.

Agglomeration and Iron Ore Pelletizing

Indirect kilns are used to agglomerate finely ground ore into uniform pellets. The controlled temperature profile ensures the pellets have consistent size and strength, which is vital for efficient handling, transport, and downstream processing in a blast furnace.

Thermal Desorption and Metals Recycling

When recycling materials, indirect kilns excel at using heat to drive off volatile contaminants like oils, plastics, or mercury from metal scrap. The controlled, oxygen-free atmosphere prevents the metals from oxidizing while ensuring the contaminants are removed safely and effectively.

Carbonization and Activation

These kilns are also used to produce high-purity carbon products, such as activated carbon. By carefully controlling the temperature and inert atmosphere, carbonaceous materials are processed to remove impurities and develop a highly porous structure, crucial for applications in purification and chemical processing.

Understanding the Trade-offs: Control vs. Efficiency

Choosing an indirect kiln involves a clear trade-off. You gain superior control and purity at the expense of thermal efficiency and cost.

Advantage: Unmatched Process Control

The ability to dictate the exact temperature and atmospheric composition inside the kiln is its single greatest advantage. This allows for the production of highly specialized, high-purity materials that meet stringent specifications.

Advantage: Material Integrity and Yield

Because the material is not in contact with high-velocity combustion gases, product loss is minimized. Delicate or fine materials are not carried away by the exhaust stream, ensuring a higher process yield.

Disadvantage: Lower Thermal Efficiency

Heating the material indirectly—through the kiln shell—is inherently less efficient than direct heat transfer. This results in longer heating times and higher energy consumption compared to a direct-fired kiln of similar size.

Disadvantage: Higher Operational and Maintenance Costs

The "kiln-within-a-furnace" design is more mechanically complex. It involves additional components like the outer furnace, specialized seals, and burner systems, leading to higher initial investment and ongoing maintenance requirements.

Making the Right Choice for Your Process

The decision to use an indirect-fired kiln should be driven by the specific requirements of your end product.

- If your primary focus is material purity and precise atmosphere control: The indirect-fired kiln is the definitive choice for sensitive materials where contamination is unacceptable.

- If your primary focus is maximizing throughput and energy efficiency: A direct-fired kiln is often more cost-effective, provided the material can tolerate direct contact with combustion gases.

- If your primary focus is processing diverse or delicate feedstocks: The gentle heating and contained environment of an indirect kiln offer superior flexibility and material yield.

Ultimately, the indirect-fired rotary kiln is a specialized tool chosen when the precision of the process environment is more critical than the raw cost of energy.

Summary Table:

| Feature | Benefit | Application |

|---|---|---|

| Isolated heating | Prevents contamination from combustion gases | Calcination of sensitive ores |

| Controlled atmosphere | Allows for oxidizing, inert, or reducing conditions | Roasting and agglomeration |

| High-purity processing | Maintains material integrity and yield | Metals recycling and carbonization |

| Lower thermal efficiency | Higher energy use but superior control | Specialized metallurgical processes |

Need a tailored high-temperature solution for your metallurgical processes? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced indirect-fired rotary kilns and other furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD. Our deep customization capabilities ensure precise handling of unique experimental requirements, delivering unmatched purity and control. Contact us today to discuss how we can optimize your thermal processing for superior results!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation