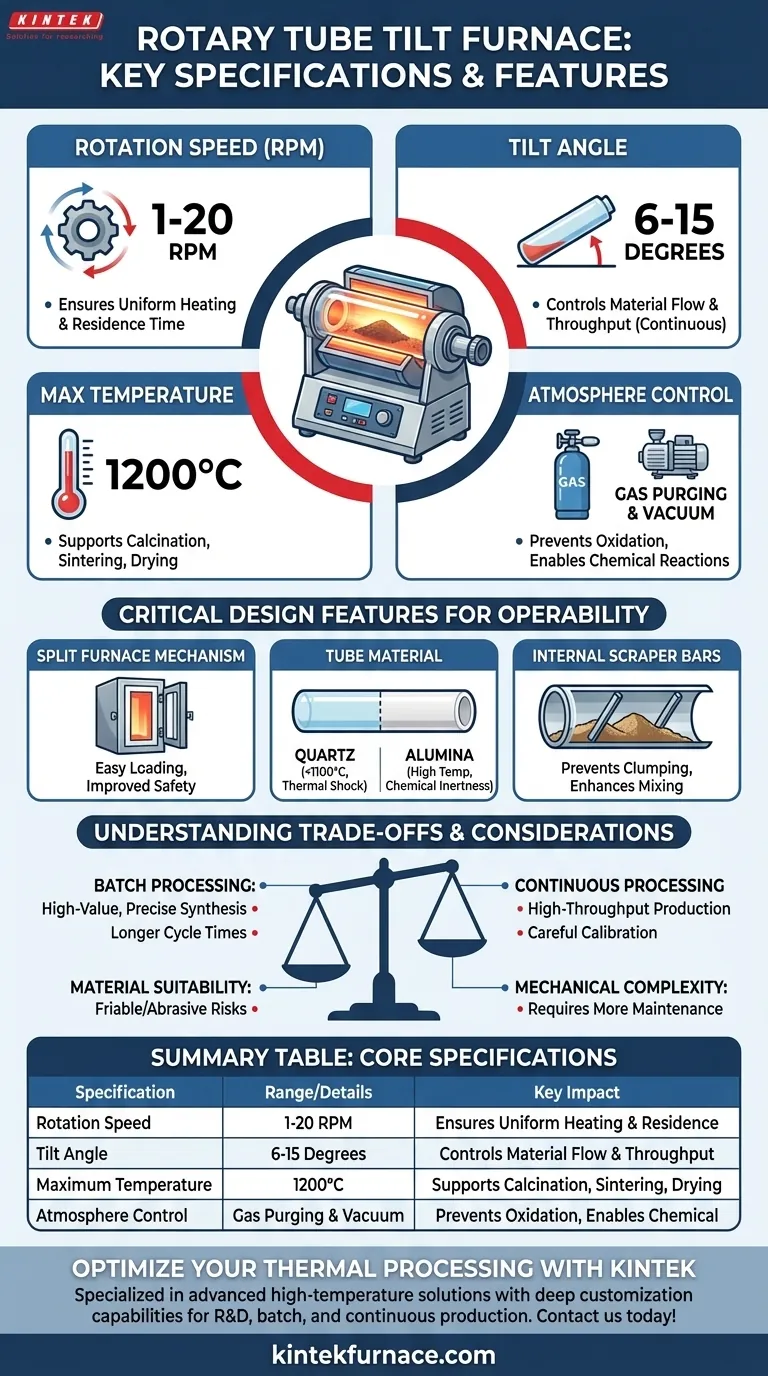

At its core, a Rotary Tube Tilt Furnace is defined by four key specifications: a rotation speed range of 1-20 RPM, a tilt angle of 6-15 degrees, a maximum operating temperature of 1200°C, and the capability for both gas purging and vacuum atmospheres. These parameters work in concert to provide precise control over the thermal processing of powders and granular materials.

A Rotary Tube Tilt Furnace is not merely a heating device; it is a dynamic processing instrument. Its specifications are designed to give you direct control over material transport, heat transfer efficiency, and the chemical environment, enabling highly consistent and repeatable results for both batch and continuous production.

Deconstructing the Core Specifications

To properly evaluate this equipment, you must understand how each specification directly impacts your process outcome. These are not just numbers on a data sheet; they are the levers you pull to control your material's transformation.

Rotation Speed (RPM): The Key to Uniformity

The specified low rotation speed, typically 1-20 RPM, is a critical feature. This gentle tumbling action continuously exposes new surfaces of the material to the heat source.

This prevents localized overheating or "hot spots" and ensures every particle receives a uniform thermal treatment. It also allows for precise control over the residence time of the material within the heated zone.

Tilt Angle: Controlling Material Flow

The ability to adjust the furnace's tilt angle, typically from 6 to 15 degrees, is what governs the flow rate of material through the tube in continuous operation.

A steeper angle results in faster material transport and lower residence time, increasing throughput. A shallower angle slows the material down, maximizing its exposure time for processes that require longer heating cycles.

Maximum Temperature: Enabling a Wide Range of Processes

A maximum temperature of 1200°C makes the furnace suitable for the vast majority of common thermal processing applications.

This includes processes like calcination, sintering of ceramics, drying, carbonization, and the thermal treatment of various chemical compounds and catalysts.

Atmosphere Control: Creating the Ideal Reaction Environment

The furnace's design allows for processing under a controlled atmosphere. This is achieved through gas purging, where an inert (like Argon or Nitrogen) or reactive gas is flowed through the tube.

This capability is essential for preventing oxidation of sensitive materials or for facilitating specific chemical reactions. Furthermore, some models offer vacuum capabilities for processes that require the removal of all atmospheric gases.

Critical Design Features for Operability

Beyond the primary process parameters, several mechanical features determine the furnace's usability, flexibility, and longevity.

Split Furnace Mechanism

Many designs feature a split mechanism, allowing the furnace body to open vertically or horizontally. This dramatically simplifies the loading and unloading of the processing tube, improving safety and reducing downtime between runs.

Tube Material: Matching the Process Chemistry

The choice of tube material is crucial. Quartz tubes are common for their thermal shock resistance and purity at temperatures typically below 1100°C.

For higher temperatures or when processing chemically aggressive materials, alumina tubes are used due to their superior refractory properties and chemical inertness.

Internal Scraper Bars

The inclusion of scraper bars or baffles inside the tube is a simple but effective feature. As the tube rotates, these bars lift and drop the material.

This action prevents clumping and ensures that the entire batch is properly mixed and agitated, further contributing to processing uniformity.

Understanding the Trade-offs

While highly versatile, a Rotary Tube Tilt Furnace has operational characteristics that present trade-offs you must consider.

Batch vs. Continuous Production

The furnace excels at both batch processing (for high-value, precise synthesis) and continuous processing (for high-throughput production). However, a system optimized for one mode may be less efficient in the other. Continuous flow requires careful calibration of tilt and rotation to achieve the desired residence time.

Material Suitability

The tumbling action, while excellent for mixing most powders and granules, may not be suitable for all materials. Extremely friable materials could be damaged or ground into finer particles, while highly abrasive materials could cause premature wear on the process tube.

Mechanical Complexity

Compared to a static box or tube furnace, the addition of rotation and tilting mechanisms introduces greater mechanical complexity. This necessitates a more rigorous preventative maintenance schedule to ensure the reliability of seals, bearings, and drive motors.

Making the Right Choice for Your Application

Your final decision should be guided by your primary processing goal.

- If your primary focus is high-throughput production (e.g., drying, bulk calcination): The adjustable tilt angle and continuous operation capability are your most critical features.

- If your primary focus is precise material synthesis (e.g., nanomaterials, catalysts): You should prioritize fine control over low RPM rotation and robust atmosphere control (gas/vacuum).

- If your primary focus is process development and R&D: A model with a wide range of adjustment in all key specifications—tilt, speed, and atmosphere—will provide the most flexibility.

Understanding these specifications empowers you to move from simply choosing a furnace to designing a truly optimized thermal process.

Summary Table:

| Specification | Range/Details | Key Impact |

|---|---|---|

| Rotation Speed | 1-20 RPM | Ensures uniform heating and precise residence time control |

| Tilt Angle | 6-15 degrees | Controls material flow rate and throughput in continuous operation |

| Maximum Temperature | 1200°C | Supports calcination, sintering, and other high-temperature processes |

| Atmosphere Control | Gas purging and vacuum capabilities | Prevents oxidation and enables specific chemical reactions |

Ready to enhance your thermal processing with precision and reliability? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Our Rotary Tube Tilt Furnaces, part of a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, are backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we ensure your equipment perfectly matches your experimental requirements—whether for R&D, batch, or continuous production. Contact us today to discuss how we can optimize your processes and deliver consistent, high-quality results!

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the advantages of a rotary tube furnace? Achieve Superior Uniformity and Efficiency in Material Processing

- What is the role of rotary tube furnaces in the energy sector? Boost Efficiency in Biomass and Battery Material Processing

- What optional features enhance the processing capabilities of rotary tube furnaces? Boost Efficiency with Advanced Customizations

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What materials are rotary tube furnaces typically constructed from? Choose the Right Tube for Your Process