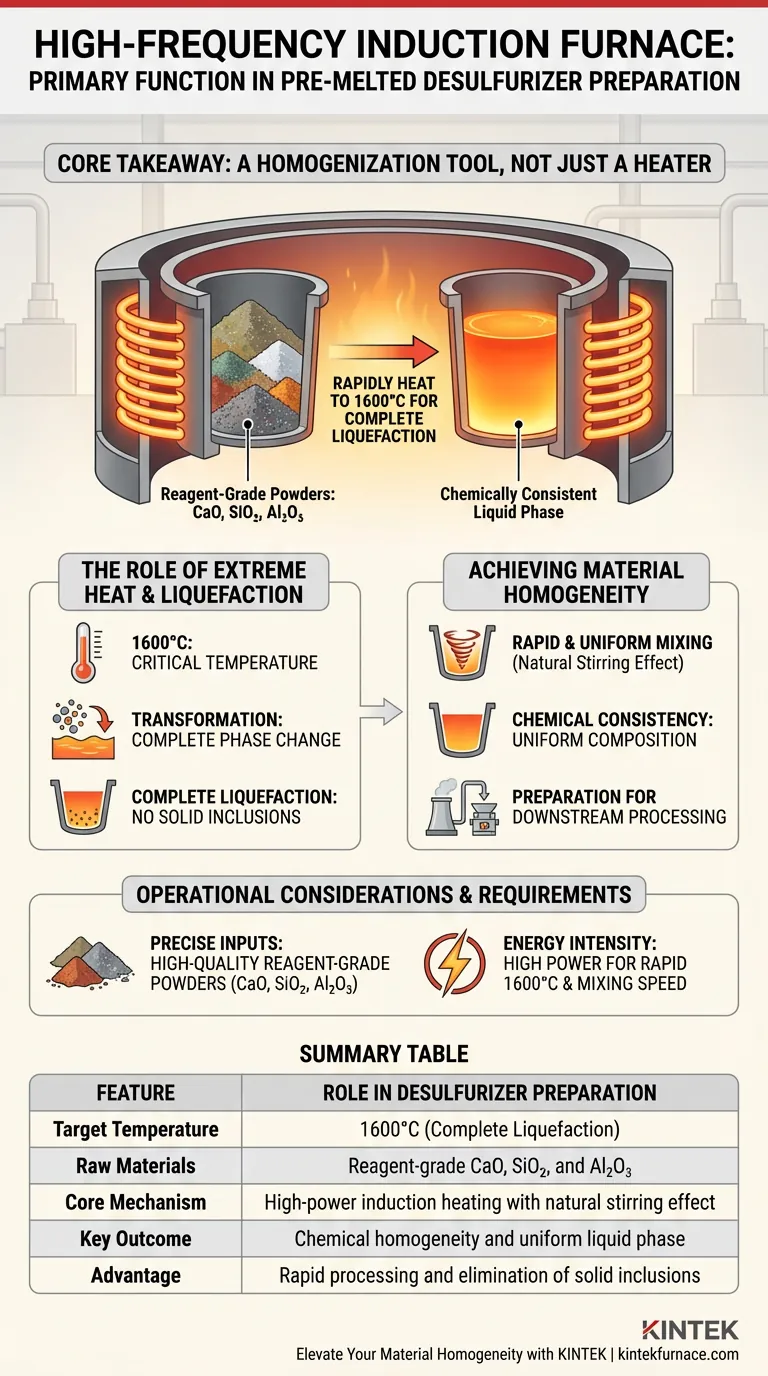

The primary function of a high-frequency induction furnace in this context is to rapidly heat mixed reagent-grade powders to 1600°C to achieve complete liquefaction. By utilizing high-power induction heating, the furnace ensures the raw materials—specifically calcium oxide, silicon dioxide, and aluminum oxide—are thoroughly melted and uniformly mixed before they are cooled and processed further.

Core Takeaway The induction furnace is not merely a heating element; it is a homogenization tool. Its ability to generate intense heat rapidly transforms heterogeneous powders into a chemically consistent liquid phase, which is the defining requirement for producing high-quality pre-melted desulfurizers.

The Role of Extreme Heat and Liquefaction

Reaching Critical Temperatures

To prepare effective pre-melted desulfurizers, the system must reach extremely high temperatures. The high-frequency induction furnace is specifically calibrated to heat the material mixture to 1600°C.

Transformation of Raw Materials

At this temperature, the solid raw materials undergo a complete phase change. The furnace converts the mixed powders of reagent-grade calcium oxide, silicon dioxide, and aluminum oxide into a molten state.

Ensuring Complete Liquefaction

Partial melting is insufficient for this application. The induction furnace provides the sustained high power necessary to ensure every particle within the batch is fully liquefied, eliminating solid inclusions that could compromise the final product.

Achieving Material Homogeneity

Rapid and Uniform Mixing

The mechanism of induction heating promotes vigorous movement within the melt. This natural stirring effect facilitates rapid and uniform mixing of the different chemical components while they are in the liquid phase.

Establishing Chemical Consistency

The ultimate goal of this pre-melting stage is consistency. By thoroughly mixing the liquefied oxides, the furnace ensures that the resulting material has a uniform chemical composition throughout the entire batch.

Preparation for Downstream Processing

This uniformity is critical for the steps that follow. The high-quality initial material produced by the furnace ensures that the subsequent cooling, crushing, and screening phases yield a reliable and effective desulfurizer.

Operational Considerations and Requirements

Requirement for Precise Inputs

The process relies heavily on the quality of the input materials. Using reagent-grade powders (CaO, SiO₂, Al₂O₃) is essential to prevent impurities from degrading the melt during the high-temperature induction process.

Energy Intensity

Reaching and maintaining 1600°C requires significant energy input. This high-power requirement is a necessary trade-off to achieve the rapid liquefaction and mixing speeds that other furnace types may not support efficiently.

Making the Right Choice for Your Goal

To ensure you are selecting the correct processing method for your materials, consider your specific purity and processing targets.

- If your primary focus is chemical uniformity: Prioritize high-frequency induction heating to leverage its natural stirring effect and ability to fully liquefy mixed oxides.

- If your primary focus is process speed: Rely on the high-power capabilities of the induction furnace to rapidly bring materials to the 1600°C melting point compared to conventional resistance heating.

The success of a pre-melted desulfurizer relies entirely on the induction furnace's ability to turn a mixture of powders into a single, chemically absolute liquid.

Summary Table:

| Feature | Induction Furnace Role in Desulfurizer Preparation |

|---|---|

| Target Temperature | 1600°C (Complete liquefaction) |

| Raw Materials | Reagent-grade CaO, SiO₂, and Al₂O₃ |

| Core Mechanism | High-power induction heating with natural stirring effect |

| Key Outcome | Chemical homogeneity and uniform liquid phase |

| Advantage | Rapid processing and elimination of solid inclusions |

Elevate Your Material Homogeneity with KINTEK

Precision in pre-melted desulfurizer production starts with superior thermal control. At KINTEK, we understand that achieving 1600°C with absolute chemical consistency is vital for your research and industrial applications. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature induction solutions—all fully customizable to meet your unique processing needs.

Don't compromise on material purity. Contact us today to optimize your lab's high-temperature processing capabilities!

Visual Guide

References

- Jyun-Ming Shen, Weite Wu. Effects of Different CaO/Al2O3 Ratios on the Phase Composition and Desulfurization Ability of CaO-Based Desulfurizers in Hot Metal. DOI: 10.3390/met14030363

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the function of a vacuum induction furnace for 6Mo steel? Precision Melting for Super-Austenitic Alloys

- What are the technical advantages of using a high vacuum arc furnace? Unlock High-Purity Magnetic Alloys

- Why is repeated melting necessary for AlCoCrFeNi2.1 HEA? Achieving Chemical Uniformity in High-Entropy Alloys

- What future applications might benefit from induction technology? Unlock Next-Gen Manufacturing & Green Energy

- What is the role of the power supply in an IGBT-based induction heater circuit? Unlock Maximum Heating Performance

- What is the crucible material in the induction furnace? Select the Right Crucible for Your Metal

- What are the main steps in vacuum casting? Master High-Quality Prototyping and Low-Volume Production

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys