The primary function of a graphite heater within a piston-cylinder assembly is to act as a precision resistive heating element. When electrical current flows through a high-purity graphite tube, it converts electrical energy into heat, creating a stable and controllable high-temperature environment for the sample chamber.

Core Insight: Graphite is uniquely suited for this role because it combines excellent electrical conductivity with a high melting point. This allows it to generate uniform heat efficiently without structurally failing under the extreme pressures characteristic of piston-cylinder experiments.

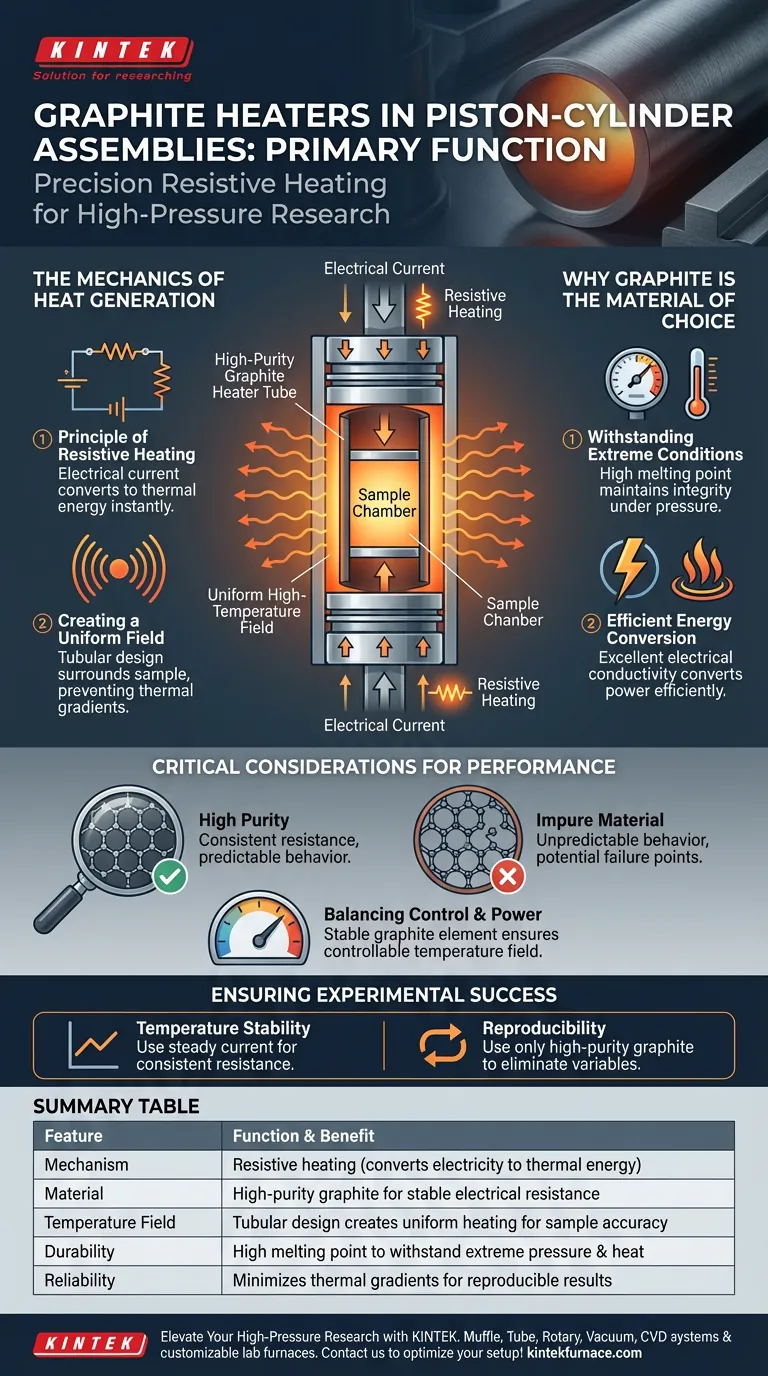

The Mechanics of Heat Generation

The Principle of Resistive Heating

The assembly operates by passing an electrical current directly through the graphite tube. Because the graphite functions as a resistor, this flow of electricity is instantly converted into thermal energy.

Creating a Uniform Field

The physical design of the heater is critical for experimental accuracy. By utilizing a tubular shape, the graphite creates a uniform high-temperature field that surrounds the sample chamber. This ensures the sample is heated evenly from all sides, preventing thermal gradients that could skew results.

Why Graphite is the Material of Choice

Withstanding Extreme Conditions

In piston-cylinder apparatuses, components must survive crushing forces. Graphite possesses a high melting point, which allows it to maintain its structural integrity and function correctly even when subjecting the sample to extreme temperatures.

efficient Energy Conversion

To function as a heater, the material must be part of an electrical circuit. Graphite offers excellent electrical conductivity, making it an ideal medium for efficiently converting electrical input into the sustained heat required for high-pressure petrology or materials science experiments.

Critical Considerations for Performance

The Necessity of High Purity

It is not enough to simply use generic graphite; the reference explicitly highlights the need for high-purity graphite. Impurities in the material can alter its resistance properties, leading to unpredictable heating behavior or potential failure points under pressure.

Balancing Control and Power

The system is designed to provide a controllable temperature field. However, this relies on the stability of the graphite element. Any degradation in the tube's quality can compromise the precise control needed to maintain specific experimental conditions.

Ensuring Experimental Success

To maximize the effectiveness of your piston-cylinder assembly, match your operational protocols to the material properties of the heater.

- If your primary focus is Temperature Stability: Ensure your electrical source provides a steady current to leverage the consistent resistive properties of the graphite.

- If your primary focus is Reproducibility: Use only high-purity graphite tubes to eliminate variables caused by material impurities or inconsistent resistance.

By leveraging the robust thermal and electrical properties of graphite, you ensure a reliable and consistent foundation for your high-pressure research.

Summary Table:

| Feature | Function & Benefit |

|---|---|

| Mechanism | Resistive heating (converts electricity to thermal energy) |

| Material | High-purity graphite for stable electrical resistance |

| Temperature Field | Tubular design creates uniform heating for sample accuracy |

| Durability | High melting point to withstand extreme pressure and heat |

| Reliability | Minimizes thermal gradients for reproducible research results |

Elevate Your High-Pressure Research with KINTEK

Precision experiments demand uncompromising hardware. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable lab high-temp furnaces tailored to your unique specifications. Whether you are conducting petrology studies or advanced materials science, our high-purity graphite solutions ensure the stability and reproducibility your data depends on. Contact us today to optimize your laboratory setup!

Visual Guide

References

- Wanying Wang, Yuan Li. Redox control of the partitioning of platinum and palladium into magmatic sulfide liquids. DOI: 10.1038/s43247-024-01366-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the hazards associated with molybdenum disilicide? Manage Risks in High-Temp Applications

- What materials are commonly used for heating elements in different temperature applications? Optimize Your Thermal Process Efficiency

- How has molybdenum been used in industrial furnaces as a heating element? Unlock High-Temp Performance Up to 1900°C

- Why are alloys used in electrical heating devices? Discover the Key to Durable, Efficient Heat Generation

- What are the common configurations of molybdenum heating elements? Choose the Right Type for Your Furnace

- What are the mechanical properties of molybdenum heating elements? A Guide to Mo vs. MoSi₂

- How does Joule heating work in heating elements? Master Efficient Heat Generation for Your Lab

- Which metals can be melted using MoSi2 heating elements? High-Temp Melting Guide