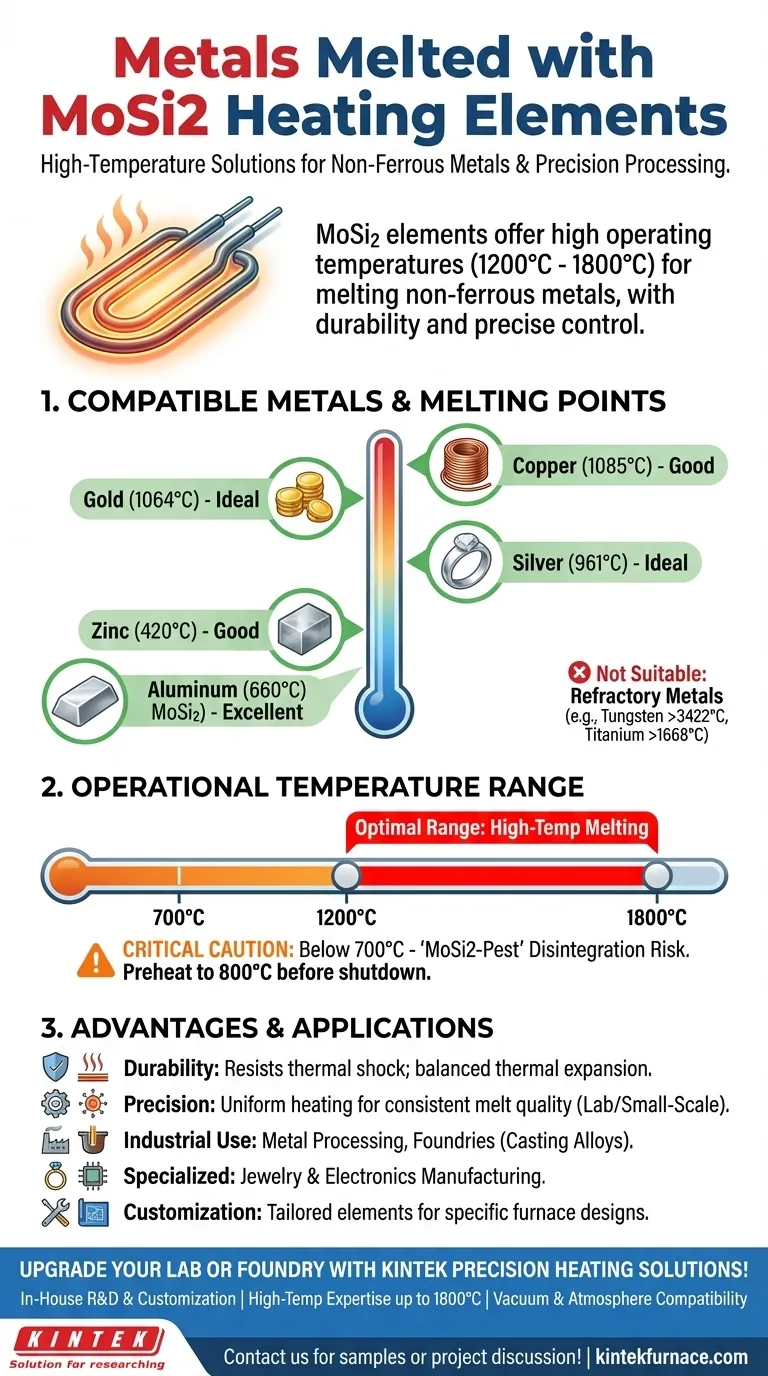

Molybdenum disilicide (MoSi2) heating elements are capable of melting several non-ferrous metals, including aluminum, gold, silver, zinc, and copper, due to their high operating temperatures (starting at 1200°C). These high temperature heating elements are widely used in metal processing, ceramics, and laboratory settings, offering durability and precise temperature control. However, they require careful handling below 700°C to avoid disintegration ("MoSi2-Pest"). Their suitability depends on the metal's melting point and the furnace's thermal management.

Key Points Explained:

-

Metals Compatible with MoSi2 Heating Elements

- Aluminum (660°C): Easily melted due to its relatively low melting point.

- Gold (1064°C) & Silver (961°C): Ideal for jewelry and electronics manufacturing.

- Zinc (420°C) & Copper (1085°C): Commonly processed in industrial applications.

- Limitation: Not suitable for refractory metals (e.g., tungsten, titanium) with melting points exceeding 1600°C.

-

Operational Temperature Range

- Optimal Range: 1200°C–1800°C, making MoSi2 ideal for high-temperature melting.

- Critical Caution: Below 700°C, the "MoSi2-Pest" phenomenon can cause disintegration. Preheating to 800°C before shutdown mitigates this risk.

-

Advantages of MoSi2 for Metal Melting

- Durability: Resists thermal shock better than silicon carbide (SiC) due to a balanced thermal expansion coefficient.

- Precision: Uniform heating ensures consistent melt quality, critical for laboratory and small-scale industrial use.

-

Industrial Applications

- Metal Processing: Used in foundries for casting non-ferrous alloys.

- Jewelry & Electronics: Melting precious metals for components and ornaments.

- Complementary Use: Often paired with stainless steel sheaths (e.g., SS310) for corrosion-resistant furnace designs.

-

Customization & Limitations

- Tailored Solutions: Elements can be customized for specific furnace geometries or thermal profiles.

- Energy Efficiency: Self-regulating properties (like PTC materials) are absent; external controllers are needed for temperature stability.

-

Comparison with Alternatives

- vs. SiC Heating Elements: MoSi2 excels in higher temperature ranges (>1500°C), while SiC is preferred for rapid thermal cycling.

- vs. Resistance Wire: MoSi2 outperforms in longevity and peak temperature capability.

For specialized needs, suppliers often provide free samples to test compatibility with specific metals or processes. Always verify the furnace’s thermal management system to avoid operational pitfalls.

Summary Table:

| Metal | Melting Point (°C) | Suitability for MoSi2 |

|---|---|---|

| Aluminum | 660 | Excellent |

| Gold | 1064 | Ideal |

| Silver | 961 | Ideal |

| Zinc | 420 | Good |

| Copper | 1085 | Good |

| Tungsten | 3422 | Not Suitable |

| Titanium | 1668 | Not Suitable |

Key Notes:

- Optimal MoSi2 operating range: 1200°C–1800°C.

- Avoid temperatures below 700°C to prevent "MoSi2-Pest."

Upgrade your lab or foundry with precision heating solutions!

KINTEK’s MoSi2 heating elements deliver unmatched durability and temperature control for melting non-ferrous metals like gold, silver, and aluminum. Whether you’re in jewelry manufacturing, electronics, or industrial metal processing, our customizable furnace components ensure optimal performance.

🔹 Why Choose KINTEK?

- In-House R&D: Tailored heating elements for your specific furnace design.

- High-Temperature Expertise: Solutions for applications up to 1800°C.

- Vacuum & Atmosphere Compatibility: Pair with our vacuum systems for advanced metallurgy.

📞 Contact us today to discuss your project or request a sample!

Products You Might Be Looking For:

Shop MoSi2 heating elements for high-temperature melting

Explore vacuum-compatible furnace components

Discover precision vacuum valves for metallurgy

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability