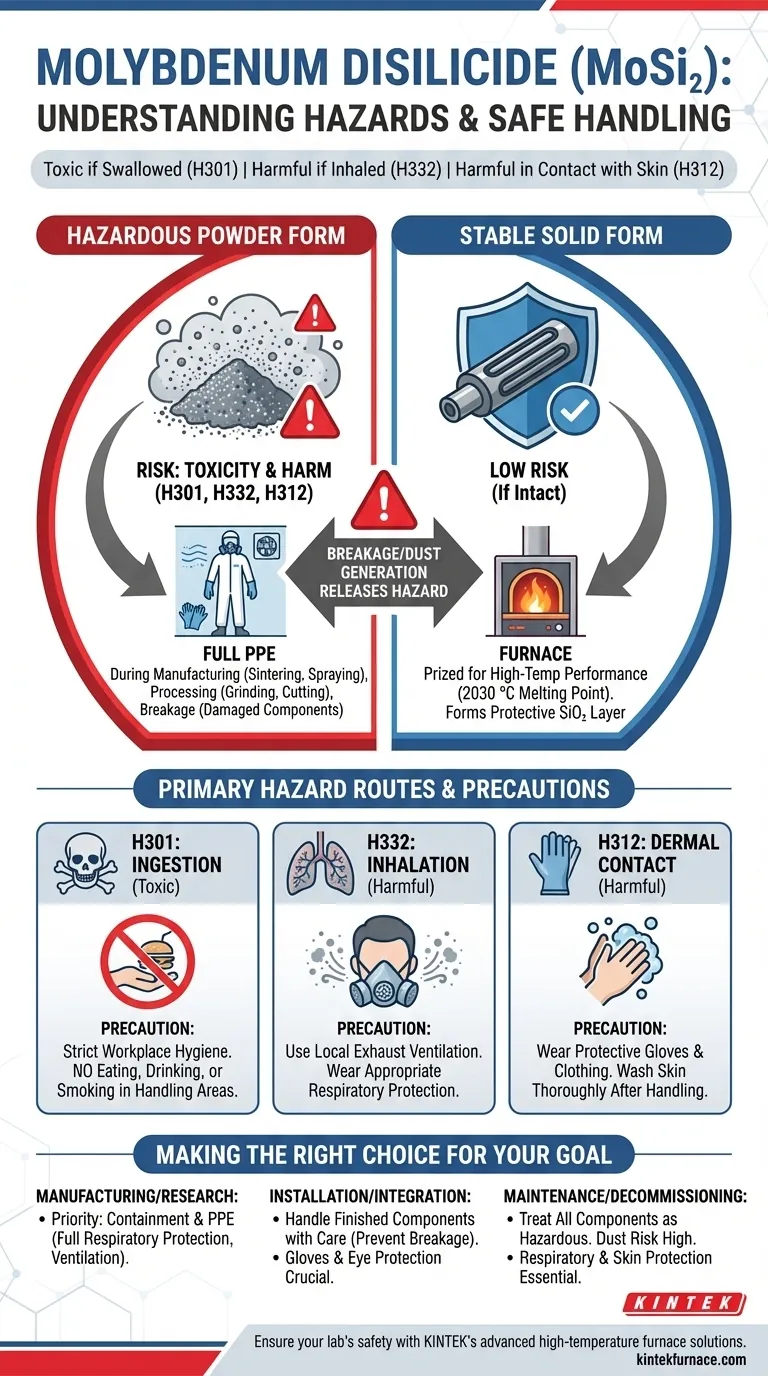

At its core, molybdenum disilicide (MoSi₂) presents a significant chemical hazard primarily when it is in a powder or dust form. According to official hazard classifications, it is toxic if swallowed (H301) and harmful if inhaled (H332) or in contact with skin (H312). These risks are most pronounced during manufacturing, processing, or when a finished component is damaged.

The central takeaway is that a material's operational stability does not negate its inherent chemical hazards. While molybdenum disilicide is exceptionally robust at high temperatures in its solid form, the primary danger lies in handling it as a raw material or powder, where exposure through inhalation, ingestion, or skin contact is possible.

Understanding the Primary Hazard Routes

Molybdenum disilicide's hazards are communicated through specific, standardized codes. Understanding each one provides a clear picture of the risks involved.

Ingestion Hazard (H301: Toxic if Swallowed)

This is the most severe warning associated with the material. Accidental ingestion, even of small quantities, can be toxic.

This underscores the importance of strict workplace hygiene, such as prohibiting eating, drinking, or smoking in areas where MoSi₂ powder is handled.

Inhalation Hazard (H332: Harmful if Inhaled)

Fine particles of molybdenum disilicide can become airborne during manufacturing processes like sintering and plasma spraying, or any activity that creates dust.

Inhaling this dust is classified as harmful. This risk necessitates the use of local exhaust ventilation and appropriate respiratory protection.

Dermal Hazard (H312: Harmful in Contact with Skin)

Prolonged or repeated contact with the skin can be harmful. The material is a gray, metallic solid, and direct handling requires protective measures.

Wearing suitable protective gloves and clothing, and washing skin thoroughly after handling, are critical precautionary steps to mitigate this risk.

Contextualizing the Risk: Solid Form vs. Powder

The physical state of the material dramatically changes its risk profile. Its primary use in heating elements relies on its properties as a dense, stable solid.

The Stable Solid Form

As a finished component, such as a heating element, molybdenum disilicide is a dense object with a very high melting point of 2030 °C (3686 °F).

At high operational temperatures, it even forms a protective passivation layer of silicon dioxide, which prevents further oxidation. In this state, the risk of exposure is minimal, provided the component remains intact.

The Hazardous Powder Form

The risks of toxicity and harm are almost exclusively associated with the material in its powder or dust state. This state is common during:

- Manufacturing: Sintering and plasma spraying are processes used to create dense parts from powder.

- Processing: Any cutting, grinding, or machining of solid parts can generate hazardous dust.

- Breakage: A fractured or damaged component can release fine particles.

Understanding the Trade-offs: Operational Utility vs. Handling Hazard

The defining characteristic of molybdenum disilicide is the stark contrast between its safety during use and its hazards during handling.

High-Temperature Performance

MoSi₂ is prized for its reliability in extreme environments. Its electrical conductivity and ability to withstand incredibly high temperatures make it an ideal material for industrial heating elements and specialized heat shields.

The Handling Reality

This operational stability creates a potential for complacency. The material is not benign. The hazards associated with the raw powder are significant and demand rigorous safety protocols.

The Critical Distinction

The key trade-off is not in its performance, but in its lifecycle management. You gain exceptional high-temperature stability in exchange for accepting the responsibility of managing a hazardous substance during all non-operational phases, from manufacturing to disposal.

Making the Right Choice for Your Goal

Your safety strategy must be tailored to how you interact with the material.

- If your primary focus is manufacturing or research: Your highest priority is containment and personal protective equipment (PPE). Assume dust will be generated and use engineering controls like ventilation and full PPE, including respiratory protection.

- If your primary focus is system integration or installation: Handle finished components with care to prevent breakage. The risk is lower, but wearing gloves and eye protection remains a crucial best practice.

- If your primary focus is maintenance or decommissioning: Treat all components as potentially hazardous. The risk of dust generation from aged or brittle parts is high, so respiratory and skin protection are essential.

Ultimately, managing the risks of molybdenum disilicide depends on recognizing when it can shift from a stable solid into a hazardous powder.

Summary Table:

| Hazard Type | Risk Description | Key Precautions |

|---|---|---|

| Ingestion (H301) | Toxic if swallowed; severe health risks from small amounts | Prohibit eating/drinking in handling areas; enforce strict hygiene |

| Inhalation (H332) | Harmful if inhaled; dust from manufacturing or breakage | Use local exhaust ventilation and respiratory protection |

| Dermal Contact (H312) | Harmful with prolonged skin contact; can cause irritation | Wear protective gloves and clothing; wash skin thoroughly after handling |

| Powder vs. Solid | Powder form is highly hazardous; solid form is stable if intact | Handle with care to prevent breakage; use engineering controls for dust |

Ensure your lab's safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Our expertise helps you manage hazardous materials like molybdenum disilicide effectively—contact us today to discuss how we can enhance your safety and performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability