At their core, molybdenum-based heating elements are defined by high mechanical strength at extreme temperatures, but their specific properties depend entirely on whether you are using pure Molybdenum (Mo) or Molybdenum Disilicide (MoSi₂). Pure molybdenum is strong but requires a vacuum environment, while MoSi₂ is more brittle when cold but offers exceptional performance and longevity in air.

The term "molybdenum heating element" refers to two distinct materials with different mechanical behaviors. Your choice depends on one critical factor: the operating atmosphere. Pure Molybdenum is for vacuum or inert gas, while Molybdenum Disilicide (MoSi₂) is for oxidizing atmospheres like air.

Understanding the Two Types of Molybdenum Elements

The mechanical properties and ideal applications for molybdenum heating elements diverge based on their composition. Confusing the two can lead to catastrophic failure.

Pure Molybdenum (Mo): Strength in a Vacuum

Pure Molybdenum is a refractory metal known for its high strength and very high melting point of 2623°C (4753°F).

It maintains significant mechanical strength in demanding industrial environments, making it suitable for elements shaped as wire, rods, or strips.

However, its primary limitation is its poor resistance to oxidation. It must be used in a vacuum or an inert gas atmosphere to prevent it from rapidly burning up at high temperatures.

Molybdenum Disilicide (MoSi₂): Durability in Air

Molybdenum Disilicide is not a pure metal but a ceramic-metallic composite. This fundamental difference grants it entirely different properties.

Its key advantage is outstanding oxidation resistance. When heated, it forms a protective, glass-like layer of silica (SiO₂) that prevents further oxidation, allowing it to operate in air at temperatures up to 1850°C.

Mechanically, MoSi₂ has the longest inherent life of all electric heating elements and can withstand rapid thermal cycling without degrading.

Key Mechanical Properties and Their Impact

The practical performance of these elements is a direct result of their mechanical characteristics at different temperatures.

High-Temperature Strength

Both pure Mo and MoSi₂ exhibit excellent strength and structural integrity at their respective operating temperatures. This allows them to support their own weight without sagging, a critical feature inside a large industrial furnace.

Brittleness and Ductility

This is the most significant mechanical trade-off. MoSi₂ is extremely brittle at room temperature and must be handled with care to avoid fracture. It behaves more like a ceramic than a metal when cold.

Pure molybdenum is more ductile at room temperature but can become brittle after prolonged use at very high temperatures, especially above its 1900°C recommended limit.

Resistance to Thermal Shock

MoSi₂ elements are exceptionally resistant to thermal shock and can be cycled up and down in temperature rapidly. This makes them ideal for processes that require fast heating and cooling.

Understanding the Trade-offs and Limitations

Selecting the right material requires acknowledging its inherent limitations. Making the wrong choice based on atmosphere is the most common and costly mistake.

The Brittleness Factor of MoSi₂

The room-temperature brittleness of Molybdenum Disilicide is its primary handling challenge. Elements must be installed carefully, as dropping them or applying mechanical stress can easily cause them to break. Once at temperature, this is less of a concern.

Atmosphere Is Everything: Oxidation vs. Vacuum

This cannot be overstated. Using a pure molybdenum (Mo) element in an air-filled furnace will cause it to oxidize and fail almost immediately.

Conversely, while an MoSi₂ element can function in a vacuum, its key advantage—oxidation resistance—is wasted. Pure Mo is often the more cost-effective choice for vacuum applications.

Stable Resistance of MoSi₂

A unique benefit of MoSi₂ is its stable electrical resistance over time. This allows you to connect new and old elements in the same circuit without issue and makes replacement simpler, as elements can often be changed while the furnace is still hot.

Making the Right Choice for Your Application

Your furnace environment and process goals are the only factors that matter when choosing between these two materials.

- If your primary focus is moderate-to-high temperature processes in a vacuum or inert atmosphere: Pure Molybdenum (Mo) is the correct and most economical choice.

- If your primary focus is very-high-temperature operation (up to 1850°C) in an air atmosphere: Molybdenum Disilicide (MoSi₂) is the required material and offers superior performance.

- If your primary focus is process flexibility, long life, and ease of maintenance: The stable resistance and durability of MoSi₂ make it the clear winner for applications that can accommodate its cost.

By matching the element's distinct mechanical properties to your operating atmosphere, you ensure reliability and prevent premature failure.

Summary Table:

| Property | Pure Molybdenum (Mo) | Molybdenum Disilicide (MoSi₂) |

|---|---|---|

| Primary Atmosphere | Vacuum or Inert Gas | Air (Oxidizing) |

| Max Operating Temp | ~1900°C | 1850°C |

| Room Temp. Brittleness | Low (Ductile) | High (Brittle) |

| Thermal Shock Resistance | Good | Excellent |

| Oxidation Resistance | Poor | Excellent |

| Key Mechanical Trait | High strength in vacuum/ inert gas | Forms protective SiO₂ layer in air; stable resistance |

Still Unsure Which Heating Element is Right for Your Furnace?

Choosing between pure Molybdenum and Molybdenum Disilicide is critical for your process's success and equipment longevity. KINTEK is here to help you make the right choice.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let our experts guide you to the optimal heating solution. Contact KINTEL today to discuss your specific application, atmosphere, and temperature needs.

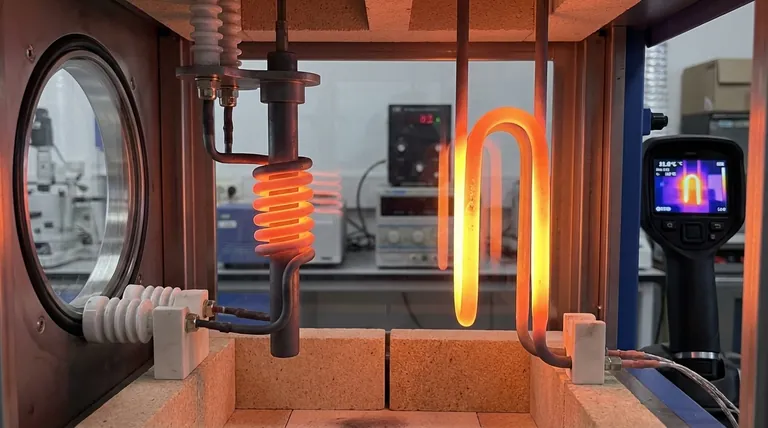

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C