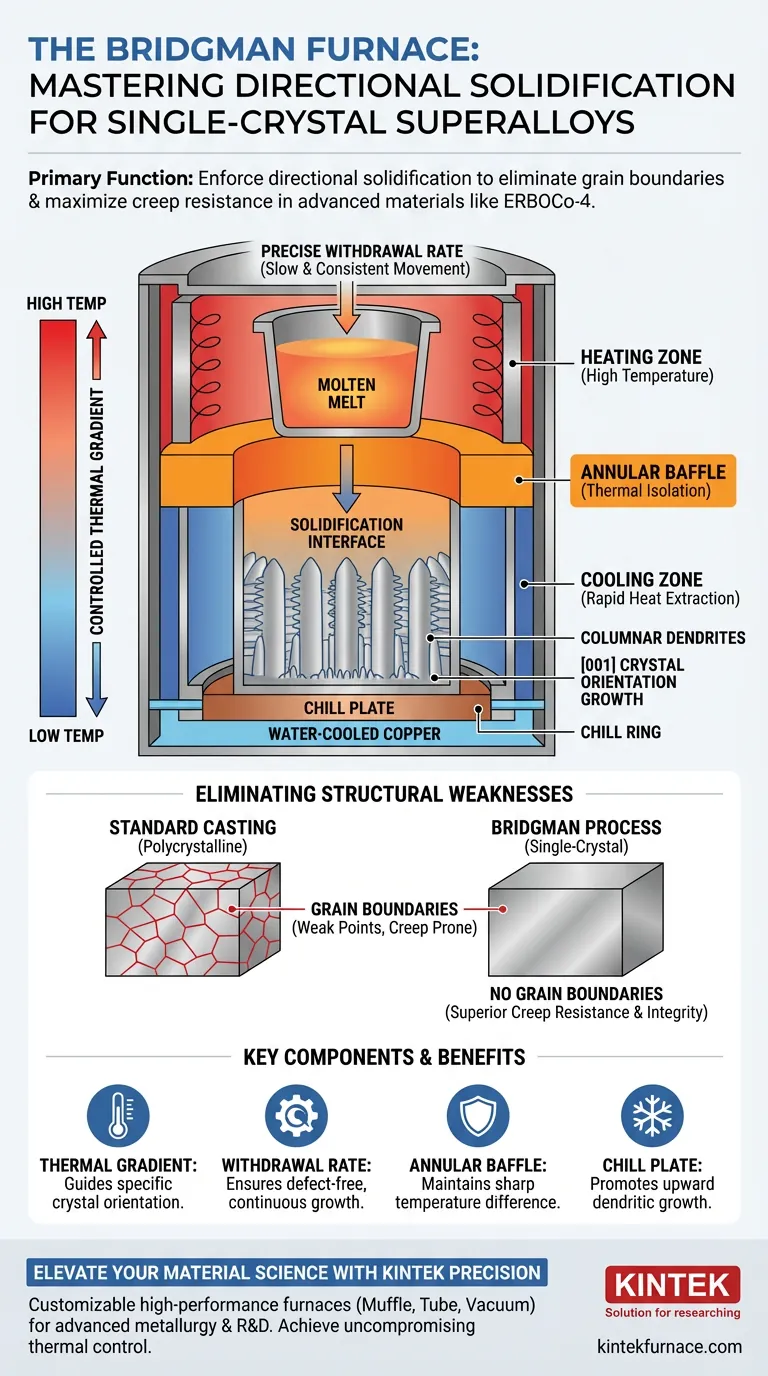

The primary function of a Bridgman Furnace is to enforce directional solidification. By strictly controlling temperature gradients and withdrawal rates, the furnace guides the crystallization of superalloy melts—such as ERBOCo-4—along specific crystal orientations. This precise thermal management ensures the material solidifies as a single, continuous crystal rather than a patchwork of multiple grains.

The Bridgman Furnace eliminates grain boundaries by managing the thermal environment during casting. This structural uniformity is critical for maximizing creep resistance and mechanical integrity in extreme, high-stress environments.

Mechanism of Action: Directional Solidification

The Bridgman Furnace is not simply a heating element; it is a complex thermal management system designed to orchestrate how a metal freezes.

Controlled Thermal Gradients

The furnace creates a specialized environment by maintaining a sharp distinction between a heating zone and a cooling zone (consisting of a chill plate and chill ring).

An insulation baffle, often called an annular baffle, sits between these zones. Its job is to maintain a high temperature gradient, preventing the heat from the top section from bleeding into the cooling section below.

Precise Withdrawal Rates

The formation of a single crystal requires movement. The furnace mechanically manages the withdrawal rate of the mold from the hot zone into the cold zone.

This movement must be slow and consistent. It ensures that the solidification interface moves through the alloy in a controlled manner, allowing the crystal structure to align perfectly without interruption.

Guiding Dendritic Growth

The combination of the temperature gradient and the withdrawal rate forces heat transfer in one specific direction.

This promotes the upward growth of columnar dendrites. Specifically, it encourages growth along the [001] crystal orientation, which serves as the fundamental hardware foundation for a stable single-crystal structure.

Eliminating Structural Weaknesses

The ultimate goal of using this furnace is to alter the microscopic architecture of the superalloy to withstand extreme conditions.

Removing Grain Boundaries

In standard casting, molten metal cools from multiple points, creating many small crystals that crash into each other. The borders where they meet are called grain boundaries.

The Bridgman process prevents these collisions. By guiding solidification in a single direction, it eliminates grain boundaries entirely.

Enhancing Creep Resistance

Grain boundaries are microscopic weak points. Under high temperatures and stress, materials tend to deform or slip along these boundaries—a failure mode known as creep.

By producing a single-crystal superalloy, the Bridgman Furnace removes these weak links. This imparts superior creep resistance and mechanical integrity, allowing the alloy to operate safely at much higher temperatures.

Understanding the Operational Complexities

While the concept is straightforward, the execution involves significant technical challenges and trade-offs.

Sensitivity to Process Variables

The "preciseness" of the control mentioned in the primary reference is non-negotiable. Even minor fluctuations in the withdrawal rate or temperature gradient can disrupt the single-crystal growth, leading to stray grains or defects.

Hardware Dependency

The quality of the final superalloy is strictly limited by the furnace hardware. If the insulation baffle fails to thermally isolate the zones, or if the chill plate does not extract heat efficiently, the required temperature gradient will collapse, and the single-crystal structure will not form.

Making the Right Choice for Your Goal

When evaluating the role of a Bridgman Furnace in your manufacturing process, consider your specific performance targets.

- If your primary focus is mechanical longevity: Prioritize the precise control of withdrawal rates to ensure the total elimination of grain boundaries, which directly correlates to creep resistance.

- If your primary focus is structural consistency: Ensure the furnace's thermal gradient is aggressive enough to strictly align the columnar dendrites along the [001] orientation.

The Bridgman Furnace is the essential manufacturing gateway for producing superalloys capable of surviving the most extreme thermal and mechanical environments.

Summary Table:

| Feature | Function in Bridgman Furnace | Benefit for Superalloys |

|---|---|---|

| Thermal Gradient | Maintains sharp heating/cooling zones | Guides growth along specific crystal orientations |

| Withdrawal Rate | Controls mold movement from hot to cold zone | Ensures continuous, defect-free crystal growth |

| Annular Baffle | Provides thermal isolation between zones | Maintains the high gradients needed for stability |

| Chill Plate | Rapid heat extraction at the base | Promotes upward columnar dendritic growth |

| Single Crystal | Complete elimination of grain boundaries | Maximizes mechanical integrity and creep resistance |

Elevate Your Material Science with KINTEK Precision

Achieving the perfect single-crystal structure requires uncompromising thermal control. At KINTEK, we specialize in the engineering of high-performance lab furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all designed to meet the rigorous demands of advanced metallurgy and R&D.

Whether you are refining superalloys like ERBOCo-4 or developing next-generation ceramics, our customizable heating solutions provide the precise gradients and stability your research deserves. Backed by expert manufacturing and a commitment to innovation, KINTEK helps you eliminate structural weaknesses and maximize material performance.

Ready to optimize your solidification process? Contact KINTEK Experts Today

Visual Guide

References

- A. Bezold, Steffen Neumeier. Segregation-induced strength anomalies in complex single-crystalline superalloys. DOI: 10.1038/s43246-024-00447-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What conditions does an autoclave provide for MoS2 hydrothermal synthesis? Achieve Optimal MoS2 Nanosheet Growth

- Why is 500°C thermal stabilization necessary for titania supports? Ensure Catalyst Stability and Performance

- What role does fluorination process equipment play in the pretreatment of LiF-BeF2 salts? Ensure High-Purity Substrates

- What is the primary function of a laboratory electric oven in food waste torrefaction? Ensure Accurate Sample Prep

- Why are reactive polyurethane systems a focus of thermal analysis in leather finishing? Balance Safety and Aesthetics

- Why is reaching a specific temperature threshold critical during the peat carbonization process? Unlock Pure Metallurgy

- What is quenching, and why is it important? Achieve Superior Material Hardness and Strength

- What are the main types of sintering methods for metals, ceramics, and refractory intermetallic compounds powders? Optimize Your Material Processing