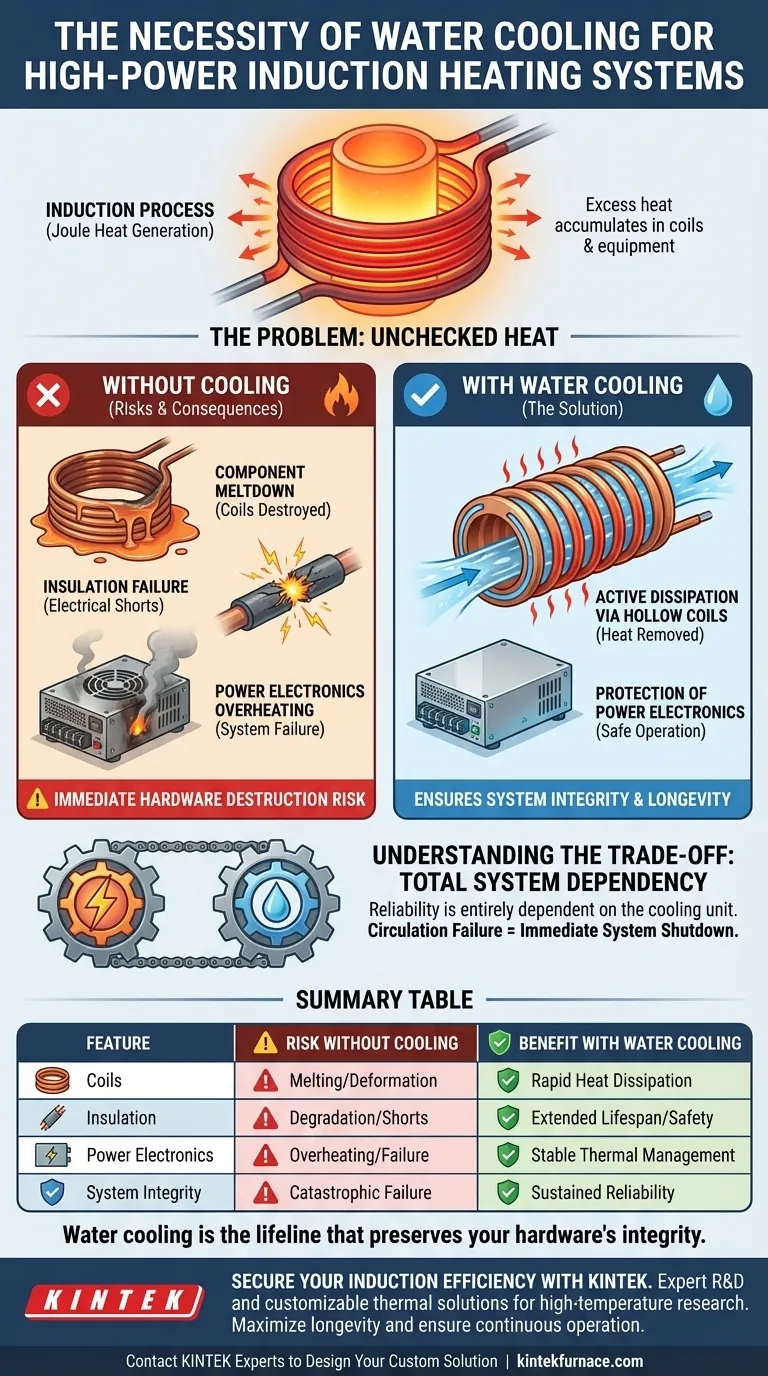

A water cooling unit is an absolute necessity for high-power induction heating systems to prevent catastrophic equipment failure. Because these systems rely on massive electrical currents to function, the induction coils themselves generate substantial internal heat (known as Joule heat). Without a dedicated active cooling mechanism, this excess heat will rapidly cause the copper coils to melt or destroy crucial electrical insulation.

While the primary goal of induction is to heat a target workpiece, the physics of the process inherently heats the machinery itself. A water cooling unit is not an accessory but a critical subsystem that ensures the induction coils and power supplies operate within safe temperature limits to prevent immediate hardware destruction.

The Thermal Physics of Induction

The Source of Internal Heat

Induction heating requires high-frequency alternating current to flow through a coil. This process generates Joule heat, which is thermal energy produced by the resistance of the coil to the electrical current.

The Scale of Thermal Load

In high-power systems, this heat is substantial. It accumulates faster than natural convection or simple air fans can dissipate it.

The Consequence of Unchecked Heat

If this heat is not actively removed, the temperature of the equipment will rise uncontrollably. This creates an immediate risk to the structural integrity of the system.

Risks of Operating Without Cooling

Component Meltdown

The most direct risk is physical deformation. Without water cooling, the intense heat can cause the induction coils to melt, permanently destroying the primary heating element.

Insulation Failure

High temperatures degrade the protective materials within the system. Excessive heat leads to insulation failure, causing electrical shorts that can damage the power supply and pose significant safety hazards.

How Water Cooling Solves the Problem

Active Dissipation via Hollow Coils

To manage this thermal load, induction systems utilize hollow copper coils. The cooling unit pumps water directly through these tubes, capturing heat from the source and carrying it away.

Protection of Power Electronics

The cooling loop often extends beyond just the coils. It is vital for maintaining the power supply components at operational temperatures, ensuring the electronics do not overheat during heavy usage.

Understanding the Operational Trade-offs

Total System Dependency

The primary trade-off in high-power induction is dependency. The reliability of your heating process is entirely dependent on the reliability of the water cooling unit.

The Consequence of Circulation Failure

If the water circulation stops or is obstructed, the induction system cannot operate safely. You must view the cooling unit and the power supply as a single, integrated ecosystem; if one fails, the other must be shut down immediately to prevent damage.

Making the Right Choice for Your Goal

To ensure your high-power induction system remains operational and safe, consider these priorities:

- If your primary focus is Equipment Longevity: Prioritize a cooling unit with sufficient flow rate to keep coils well below their thermal limits, preventing gradual insulation degradation.

- If your primary focus is Continuous Operation: Ensure your cooling solution is robust enough to handle the "substantial Joule heat" generated during long duty cycles without saturation.

A high-power induction system cannot function without water cooling; it is the lifeline that preserves the integrity of your hardware.

Summary Table:

| Feature | Risk Without Cooling | Benefit With Water Cooling |

|---|---|---|

| Induction Coils | Physical melting and deformation | Rapid dissipation of Joule heat |

| Electrical Insulation | Degradation and electrical shorts | Extended lifespan and operational safety |

| Power Electronics | Overheating and power supply failure | Stable thermal management for continuous use |

| System Integrity | Catastrophic hardware failure | Sustained reliability under high thermal loads |

Secure Your Induction Efficiency with KINTEK

Don't let excessive Joule heat compromise your laboratory’s productivity. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our high-power induction systems, alongside our Muffle, Tube, Rotary, Vacuum, and CVD systems, are all customizable to meet your unique high-temperature research needs.

Maximize equipment longevity and ensure continuous operation today.

Contact KINTEK Experts to Design Your Custom Solution

Visual Guide

References

- Débora de Figueiredo Luiz, Jurriaan Boon. Use of a 3D Workpiece to Inductively Heat an Ammonia Cracking Reactor. DOI: 10.3390/suschem6040043

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the experimental advantages of using a vacuum induction furnace for cast iron desulfurization research?

- What industries commonly use vacuum casting and for what applications? Discover Versatile Solutions for Prototyping and High-Performance Parts

- What is the working principle of a medium frequency induction furnace? Achieve Rapid, Precise Metal Melting

- What industries commonly use induction-heated vacuum furnaces? Unlock High-Purity, High-Performance Material Processing

- What are the advantages of vacuum induction furnace melting for superalloys? Achieve Purity and Performance

- In what ways are induction furnaces cost-effective? Unlock Major Energy & Material Savings

- How do induction furnaces improve working conditions? A Safer, Cleaner Foundry Environment

- What materials can induction furnaces melt? A Guide to Metals and Alloys