In short, induction furnaces are cost-effective because they fundamentally change how heat is generated, leading to dramatic gains in energy efficiency, significant reductions in material waste, and lower operational overhead. Unlike traditional furnaces that heat an entire chamber, induction technology directly and rapidly heats only the metal itself, eliminating wasted energy and time.

The true cost-effectiveness of an induction furnace is not just about a lower energy bill. It stems from a holistic set of advantages—from saving raw material to reducing maintenance—that lowers the total cost of ownership across the entire production lifecycle.

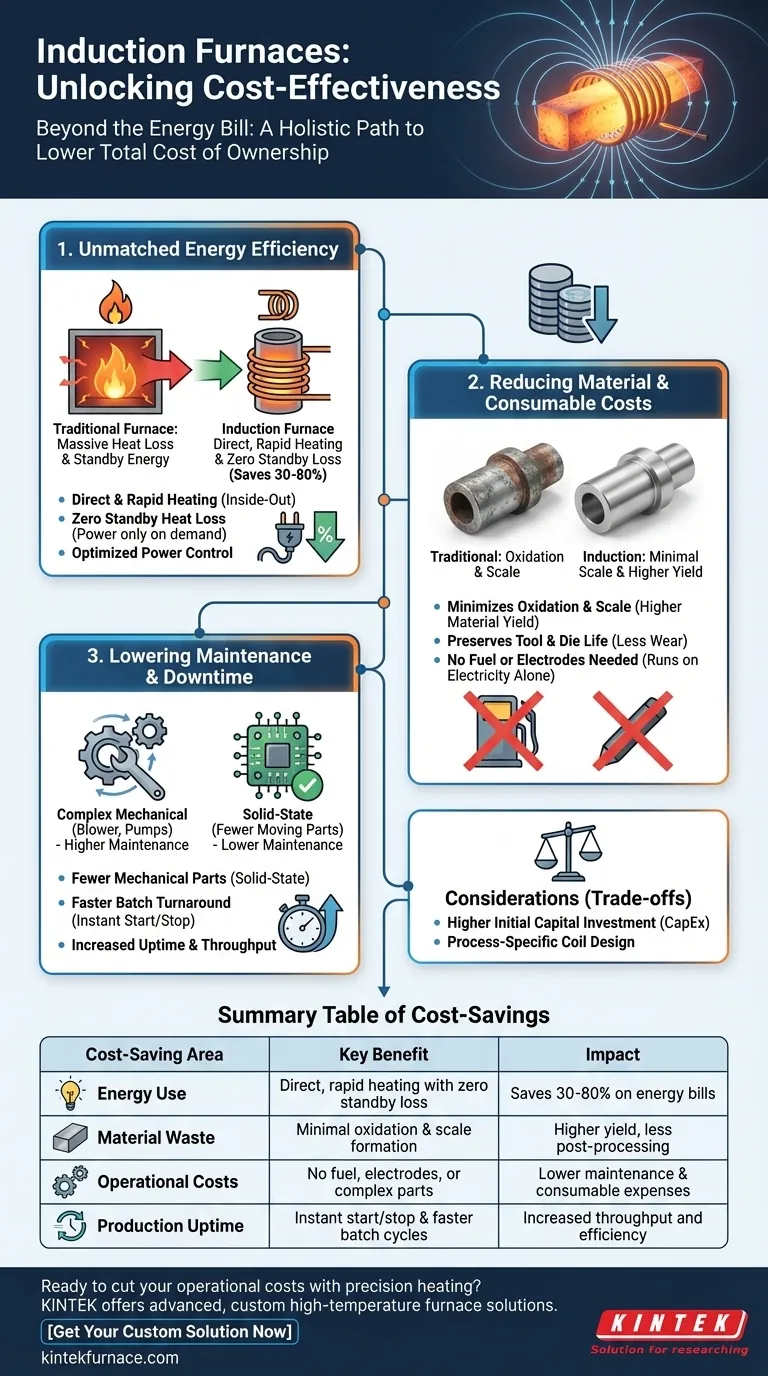

The Core Principle: Unmatched Energy Efficiency

The primary financial benefit of induction technology comes from its radically different approach to heating. It doesn't burn fuel or use slow-heating resistive elements; it uses clean, controllable electromagnetism.

Direct and Rapid Heating

An induction furnace works much like a transformer. An alternating current in the furnace's coil creates a powerful magnetic field that induces electrical currents directly within the metal part, generating precise and rapid heat.

This method is exceptionally efficient because it heats the material from the inside out, avoiding the massive heat loss that occurs when trying to heat the air and walls of a large furnace chamber.

Eliminating Standby Energy Loss

Conventional furnaces must be kept at or near operating temperature between cycles to avoid lengthy preheating times, consuming significant energy even when idle.

Induction furnaces have zero standby heat loss. Power is consumed only when a part is being actively heated, providing energy savings of 30% to 80% compared to traditional methods.

Optimized Power Control

Modern induction systems use advanced frequency and power controls to apply energy exactly where and when it is needed. This precision ensures that no energy is wasted by overshooting a target temperature, a common issue in less controllable systems.

Reducing Material and Consumable Costs

Efficiency gains extend beyond just energy. Induction heating helps you get more out of your raw materials and supporting equipment.

Minimizing Oxidation and Scale

The rapid heating speed of induction dramatically reduces the time the metal is exposed to oxygen at high temperatures. This minimizes oxidation (scale formation) and decarburization.

Less scale means less material is lost in the heating process, improving yield. It also results in a cleaner final product, often reducing the need for post-processing steps like shot blasting or machining.

Preserving Tool and Die Life

For applications like forging, the reduction in abrasive scale on the workpiece directly translates to longer life for expensive forging dies. Less wear on tooling reduces replacement costs and maintenance downtime.

No Need for Fuel or Electrodes

Induction furnaces run on electricity alone. This completely eliminates the ongoing cost of purchasing fuel, such as natural gas or coke, and removes the need for fuel handling infrastructure and associated safety risks. It also avoids the cost of consumable graphite electrodes used in some electric arc furnaces.

Understanding the Trade-offs

While highly cost-effective in operation, induction technology is not a universal solution without its own considerations. True expertise requires acknowledging the complete picture.

Higher Initial Capital Investment

The initial purchase and installation cost (CapEx) for an induction system is often higher than for a simple fuel-fired furnace. The technology is more sophisticated, requiring specialized power supplies and cooling systems.

Process-Specific Coil Design

The induction coil must be designed to efficiently couple with the specific size and shape of the part being heated. While versatile coils exist, achieving maximum efficiency for a highly varied mix of products may require multiple coils, adding to the initial cost and setup time.

Lowering Long-Term Maintenance and Downtime

An often-overlooked financial benefit is the reliability and uptime of induction systems.

Fewer Mechanical Parts

Induction furnaces are solid-state systems with very few moving parts compared to fuel-based systems that involve blowers, pumps, and fuel lines. This inherent simplicity leads to greater durability and significantly lower routine maintenance costs over the life of the equipment.

Faster Batch Turnaround

The ability to start and stop the heating process instantly means there is almost no time spent preparing the furnace for the next batch. This reduction in operational downtime allows for higher production throughput and greater overall plant efficiency.

Making the Right Choice for Your Goal

Ultimately, the decision to invest in an induction furnace should be based on your specific production priorities.

- If your primary focus is maximum energy reduction: Induction is the superior choice due to its direct heating method and complete elimination of standby energy loss.

- If your primary focus is material quality and yield: Induction's rapid, controlled heating minimizes scale and preserves metal integrity, making it ideal for high-value alloys and precision applications.

- If your primary focus is high-volume, repeatable production: The speed, precise digital control, and fast turnaround of induction heating deliver unmatched throughput and consistency.

Evaluating your heating technology based on its total cost of ownership will empower you to make the most financially sound decision for your operation.

Summary Table:

| Cost-Saving Area | Key Benefit | Impact |

|---|---|---|

| Energy Use | Direct, rapid heating with zero standby loss | Saves 30-80% on energy bills |

| Material Waste | Minimal oxidation and scale formation | Higher yield, less post-processing |

| Operational Costs | No fuel, electrodes, or complex mechanical parts | Lower maintenance and consumable expenses |

| Production Uptime | Instant start/stop and faster batch cycles | Increased throughput and efficiency |

Ready to cut your operational costs with precision heating?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions tailored to your unique needs. Our product line, including Induction, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your experimental and production requirements.

Contact us today to discuss how our induction furnace technology can enhance your efficiency and profitability.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating