Induction furnaces fundamentally transform the foundry environment by eliminating many of the most hazardous elements of traditional melting. Unlike fuel-fired furnaces, they use a clean, contained electromagnetic field to melt metal. This process drastically reduces airborne pollutants, ambient heat, and noise, creating a significantly safer and more comfortable workspace for operators.

The core improvement is a shift from an open, combustion-based process to a contained, electrically-driven one. This change directly addresses the primary occupational hazards of foundry work—air quality, noise, and heat exposure—resulting in a tangibly healthier and safer environment for the workforce.

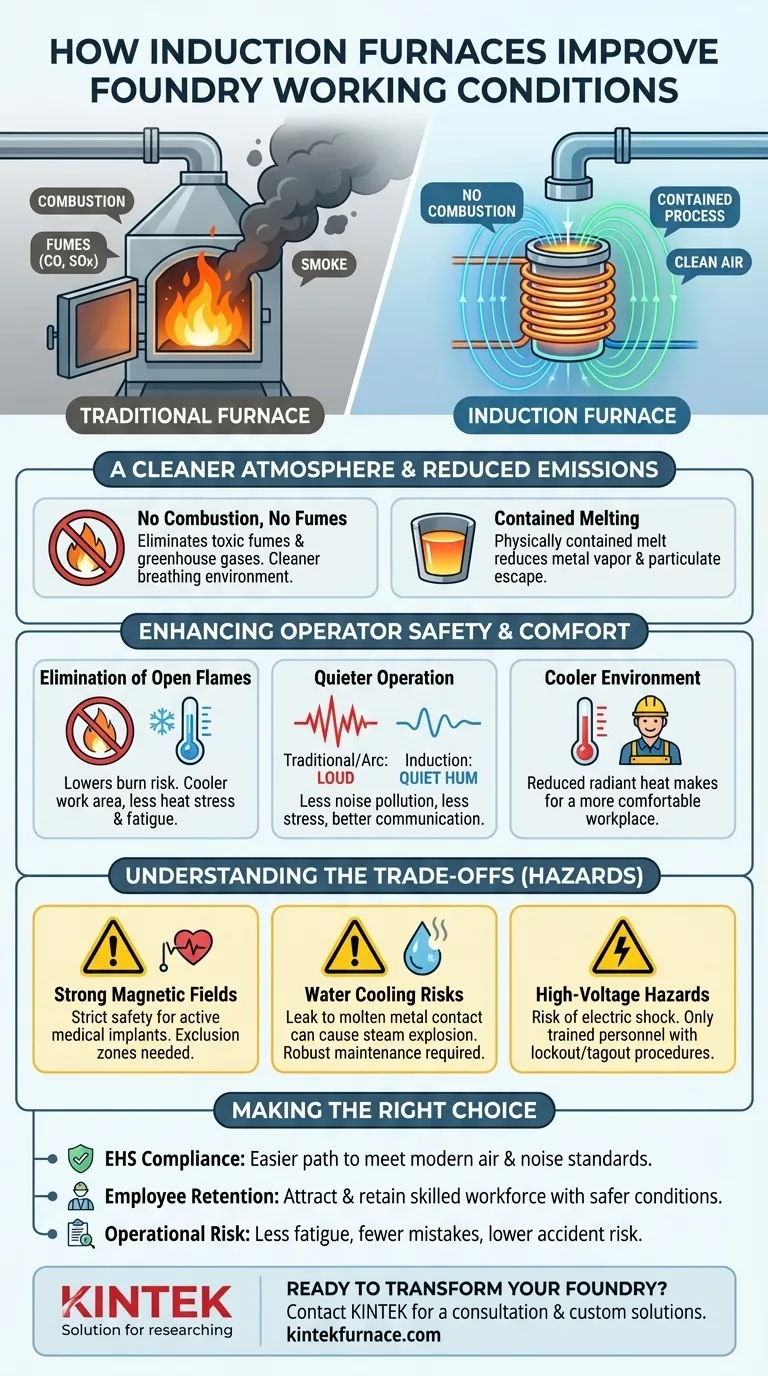

A Cleaner Atmosphere: Reducing Harmful Emissions

One of the most significant benefits of induction melting is the dramatic improvement in air quality. This is a direct result of how the technology generates heat.

No Combustion, No Fumes

Traditional cupola or reverberatory furnaces burn fossil fuels like coke or natural gas. This combustion process releases significant volumes of harmful byproducts, including carbon monoxide (CO), sulfur oxides (SOx), and smoke, directly into the work environment and atmosphere.

Induction furnaces generate heat using electricity and magnetism. With no combustion, these toxic fumes and greenhouse gases are entirely eliminated from the process, creating a cleaner breathing environment for everyone on the foundry floor.

Contained Melting Reduces Pollutants

The melting process itself is contained within the furnace crucible. This physical containment, combined with the absence of turbulent combustion gases blowing over the melt, significantly reduces the amount of metal vapor and particulate matter that can escape into the air.

Enhancing Operator Safety and Comfort

Beyond air quality, induction technology addresses other critical factors that define the daily experience and long-term health of foundry workers.

Elimination of Open Flames

The absence of open flames is a major safety upgrade. It immediately lowers the risk of accidental burns and reduces the ambient radiant heat projected into the workspace.

A cooler work area means less risk of heat stress and fatigue for operators, allowing them to remain more focused and alert, which further enhances operational safety.

Quieter Furnace Operation

Fuel-fired furnaces and especially electric arc furnaces are notoriously loud, often generating noise levels that require mandatory hearing protection and can contribute to long-term hearing damage.

Channel and coreless induction furnaces operate with a comparatively low-level hum. This drastic reduction in noise pollution makes for a less stressful environment and improves communication between team members on the floor.

Understanding the Trade-offs

While induction furnaces offer clear advantages for working conditions, they introduce their own set of specific hazards that require diligent management.

Strong Magnetic Fields

Induction furnaces generate powerful electromagnetic fields (EMF). Strict safety protocols must be enforced to protect workers with active medical implants, such as pacemakers. Signage and exclusion zones are essential.

Water Cooling System Risks

The high-power induction coils require water cooling. A leak that allows water to come into contact with molten metal can cause a catastrophic steam explosion. Robust preventative maintenance and leak detection systems are non-negotiable safety requirements.

High-Voltage Electrical Hazards

These are high-power electrical systems that present a significant risk of electric shock. Only trained and authorized personnel should ever perform maintenance, and strict lockout/tagout procedures must be followed.

Making the Right Choice for Your Goal

Adopting induction technology is a strategic decision that impacts safety, compliance, and employee well-being.

- If your primary focus is meeting modern EHS standards: Induction furnaces provide a direct path to compliance by drastically reducing the noise and air emissions that are heavily regulated.

- If your primary focus is employee retention and satisfaction: The cleaner, safer, and more comfortable environment created by induction technology is a powerful tool for attracting and retaining skilled operators in a competitive labor market.

- If your primary focus is reducing operational risk: A less fatigued and more comfortable workforce is a more alert workforce, which directly translates to fewer mistakes and a lower risk of costly or dangerous accidents.

Investing in induction technology is not merely a process upgrade; it is a fundamental investment in the health, safety, and productivity of your people.

Summary Table:

| Improvement Area | Traditional Furnace Hazard | Induction Furnace Benefit |

|---|---|---|

| Air Quality | Toxic fumes (CO, SOx) from combustion | No combustion; cleaner breathing air |

| Operator Safety | Open flame burn risk, radiant heat | Contained melting, cooler ambient temperature |

| Noise Levels | Loud operation requiring hearing protection | Quieter hum, less stress, better communication |

| Compliance | High emissions and noise regulation challenges | Easier path to meeting modern EHS standards |

Ready to transform your foundry's working conditions?

At KINTEK, we understand that a safer, cleaner workplace is crucial for compliance, employee retention, and operational excellence. Leveraging our exceptional R&D and in-house manufacturing, we provide advanced induction furnace solutions tailored to your specific needs.

Our product line, including Coreless and Channel Induction Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique melting requirements. Let us help you invest in the health and productivity of your team.

Contact KINTEL today for a consultation and discover the right induction solution for your goals.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process