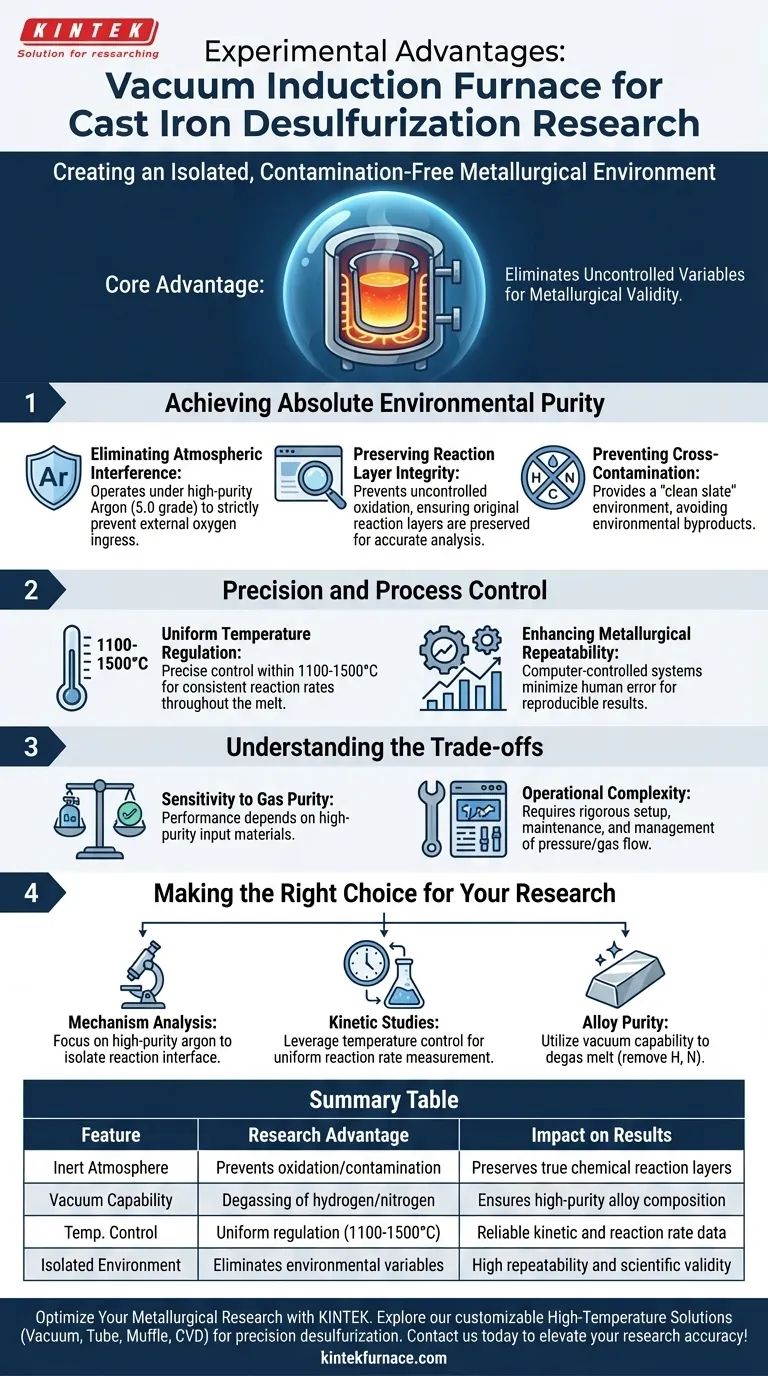

The distinct experimental advantage of using a vacuum induction furnace lies in its ability to create an isolated, contamination-free metallurgical environment. By operating under a high-purity argon atmosphere (typically 5.0 grade), the system effectively negates the ingress of external oxygen. This isolation is critical for identifying the true chemical interactions between desulfurizing agents and molten iron without the data corruption caused by atmospheric oxidation.

The primary value of a vacuum induction furnace in desulfurization research is the elimination of uncontrolled variables. By removing atmospheric interference, researchers can attribute chemical changes and reaction layer formation exclusively to the experimental inputs, ensuring metallurgical validity.

Achieving Absolute Environmental Purity

Eliminating Atmospheric Interference

The most critical challenge in desulfurization research is distinguishing between reactions caused by the experimental agents (such as lime or ash) and those caused by the surrounding air.

A vacuum induction furnace solves this by allowing operation under a controlled, high-purity argon atmosphere at 1 atmosphere of pressure. This setup strictly prevents external oxygen from entering the reaction chamber.

Preserving Reaction Layer Integrity

When oxygen is present, it creates oxide layers that can obscure the actual metallurgical processes occurring at the interface of the iron and the desulfurizer.

By preventing uncontrolled oxidation, the furnace ensures that the original reaction layers formed between the additives and the molten iron are preserved. This allows researchers to accurately analyze the specific mechanisms of desulfurization.

Preventing Cross-Contamination

Beyond oxygen, standard atmospheric furnaces introduce variables like nitrogen, hydrogen, and carbon contamination.

Vacuum furnaces provide a "clean slate" environment. This ensures that the final chemical composition of the cast iron is a result of the intended alloy manipulation, not environmental byproducts.

Precision and Process Control

Uniform Temperature Regulation

Desulfurization is a temperature-dependent kinetic process. Reliable research data requires that the entire melt stays at a consistent temperature.

These furnaces offer precise temperature control, typically within the 1100-1500°C range. This uniformity ensures that reaction rates are consistent throughout the molten metal, leading to reproducible data.

Enhancing Metallurgical Repeatability

Scientific research depends on the ability to repeat an experiment and achieve the same results.

Because the vacuum furnace uses computer-controlled heating and gas flow systems, it minimizes human error and environmental variables. This high level of automation guarantees that the conditions for desulfurization remain constant across multiple experimental runs.

Understanding the Trade-offs

Sensitivity to Gas Purity

While the furnace is capable of creating a pristine environment, its performance is entirely dependent on the quality of the input materials.

If the argon gas used is not of high purity (e.g., below 5.0 grade), the "vacuum" advantage is compromised. The system does not magically clean dirty inputs; it simply preserves the purity of what is introduced.

Operational Complexity

Compared to standard open-air furnaces, vacuum induction systems require more rigorous setup and maintenance.

Managing pressure levels, gas flow rates, and vacuum seals adds a layer of complexity to the experimental procedure. A failure in the vacuum seal or gas delivery system can render a dataset invalid due to unseen contamination.

Making the Right Choice for Your Research

To maximize the utility of a vacuum induction furnace for your specific desulfurization goals:

- If your primary focus is Mechanism Analysis: Prioritize the use of high-purity argon to isolate the reaction interface and preserve the original reaction layers between the ash/lime and iron.

- If your primary focus is Kinetic Studies: Leverage the furnace's temperature control systems to maintain strict uniformity in the 1100-1500°C range, ensuring reaction rates are measured accurately.

- If your primary focus is Alloy Purity: Utilize the vacuum capability to degas the melt, actively removing hydrogen and nitrogen before introducing desulfurizing agents.

The vacuum induction furnace transforms desulfurization from a rough industrial approximation into a precise, observable science.

Summary Table:

| Feature | Research Advantage | Impact on Results |

|---|---|---|

| Inert Atmosphere | Prevents atmospheric oxidation & contamination | Preserves true chemical reaction layers |

| Vacuum Capability | Degassing of hydrogen and nitrogen | Ensures high-purity alloy composition |

| Temp. Control | Uniform regulation (1100-1500°C) | Reliable kinetic and reaction rate data |

| Isolated Environment | Eliminates uncontrolled environmental variables | High repeatability and scientific validity |

Optimize Your Metallurgical Research with KINTEK

Precision desulfurization and alloy development require absolute control over your thermal environment. KINTEK provides industry-leading high-temperature solutions, including Vacuum, Tube, Muffle, and CVD systems, all backed by expert R&D and manufacturing.

Whether you need to isolate reaction layers or achieve uniform temperature regulation, our furnaces are fully customizable to meet your unique laboratory needs.

Ready to elevate your research accuracy? Contact KINTEK today for a customized quote and see how our advanced furnace technology can transform your experimental outcomes.

Visual Guide

References

- Ida B. G. S. Adhiwiguna, Rüdiger Deike. Observation on Reaction Mechanism of Lime Powder as Desulfurization Agent for Molten Cast Iron. DOI: 10.1002/srin.202500052

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why does the preparation of high-entropy alloys require a vacuum arc furnace? Ensure Homogeneity & Purity.

- What are the main components of an aluminum shell structure induction furnace? A Guide to Efficient, Cost-Effective Melting

- What are the advantages of an Induction Cold Crucible Furnace (ICCF) for Nb-MASC? Achieve Ultimate High-Purity Melting

- Why is high-purity argon gas utilized during the melting of AlCoCrFeNi2.1 alloys? Ensure Peak Alloy Purity

- How does frequency affect the heating efficiency in an induction furnace? Optimize Your Process with the Right Frequency

- What are the raw materials for induction furnace? The Essential Guide to Charge & Construction Materials

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery

- What makes induction furnaces suitable for precious metals processing? Unlock Purity and Efficiency in Metal Melting