The preparation of high-entropy alloys requires these specific processes to achieve absolute chemical uniformity. High-entropy alloys (HEAs) are composed of multiple elements with vastly different physical properties, making them naturally prone to separation. A vacuum arc furnace equipped with electromagnetic stirring or subjected to multiple remelting processes utilizes thermal convection and mechanical force to ensure that even trace elements are fully diffused, eliminating macro-segregation within the alloy matrix.

High-entropy alloys face a natural tendency to segregate because their constituent elements often possess conflicting densities and melting points. The combination of electromagnetic stirring and repeated remelting in a vacuum is the critical mechanism required to force these disparate materials into a single, homogeneous solid solution.

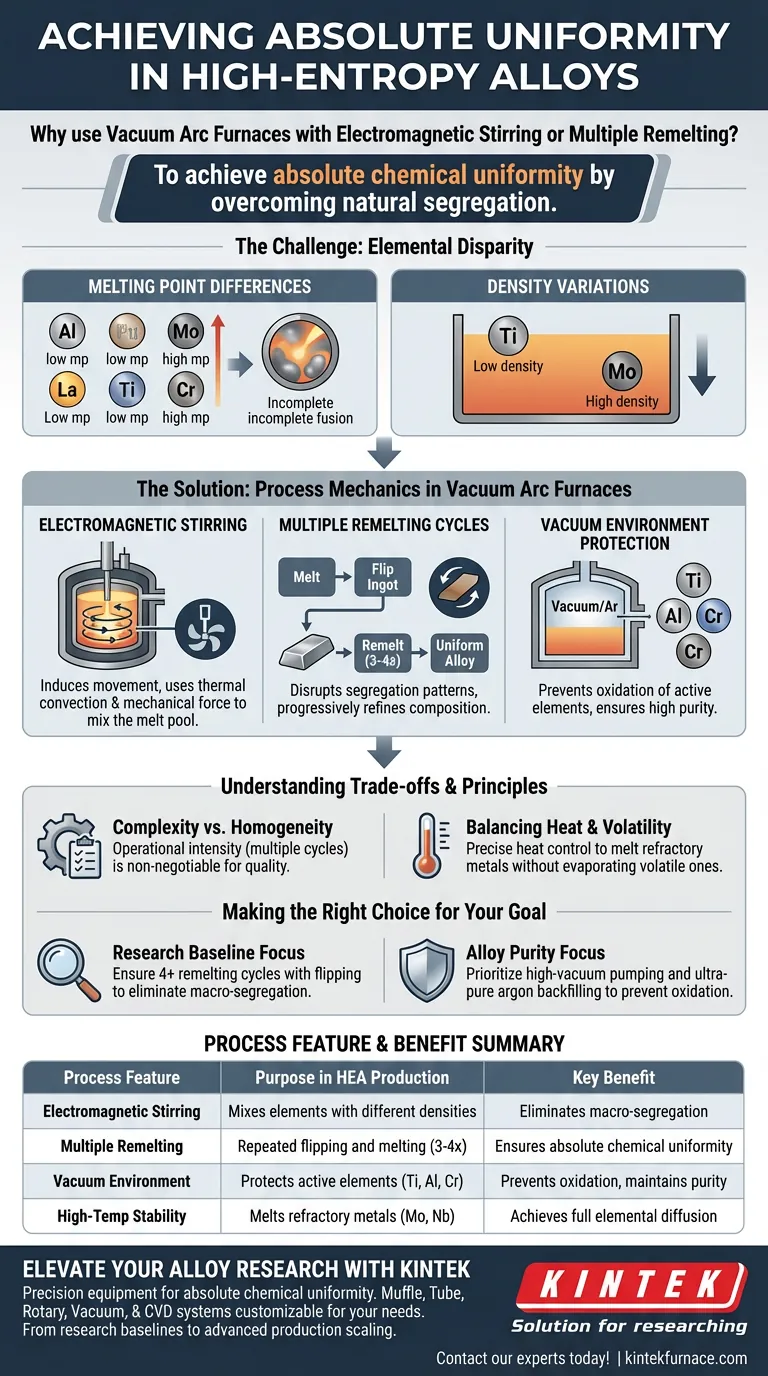

The Challenge of Elemental Disparity

Creating a high-entropy alloy is not merely about melting metals together; it is about overcoming the physical differences that drive them apart.

Overcoming Melting Point Differences

HEAs often combine metals with significantly different melting points, such as aluminum and titanium mixed with refractory metals like molybdenum or niobium. Without aggressive intervention, high-melting-point elements may not fully fuse, or low-melting-point elements may separate, leading to structural inconsistencies.

Addressing Density Variations

The elements used in these alloys, such as titanium and molybdenum, have different atomic radii and densities. In a static melt, heavier elements would naturally sink while lighter ones float. The processing method must counteract this gravity-driven separation to achieve a consistent distribution of elements at both macroscopic and microscopic scales.

The Role of Process Mechanics

To solve the segregation issue, the manufacturing process relies on specific mechanical and thermal dynamics provided by the vacuum arc furnace.

The Power of Electromagnetic Stirring

Electromagnetic stirring creates a dynamic environment within the melt pool. This process utilizes magnetic fields to induce movement, effectively using thermal convection and mechanical driving forces to mix the molten metal. This vigorous agitation ensures that difficult-to-diffuse elements, such as carbon or molybdenum, are distributed evenly throughout the matrix.

The Necessity of Multiple Remelting Cycles

A single melting pass is rarely sufficient to achieve homogeneity. The standard procedure typically requires flipping and remelting the ingot at least three to four times. Each cycle disrupts any forming segregation patterns, progressively refining the chemical composition until the alloy is uniform throughout.

Environmental Protection via Vacuum

High-entropy alloys frequently contain active elements like aluminum, titanium, and chromium, which oxidize rapidly at high temperatures. The vacuum arc furnace operates in a high-vacuum or inert gas (argon) environment. This prevents the oxidative loss of these active elements and removes adsorbed gases, ensuring the final ingot maintains high purity and precise chemical accuracy.

Understanding the Trade-offs

While this rigorous processing is necessary, it requires careful management to avoid introducing new defects.

Complexity vs. Homogeneity

The primary trade-off in this process is the operational intensity required to achieve quality. Simple melting is faster but results in unusable, segregated ingots. The requirement for multiple flipping and remelting cycles increases energy consumption and processing time but is the non-negotiable cost for obtaining a scientifically valid baseline for microstructure research.

Balancing Heat and Volatility

While high heat is needed to melt refractory elements, the vacuum environment must be managed to prevent the evaporation of volatile elements. The process relies on the precise control of the electric arc to generate localized high heat without destabilizing the alloy's overall composition.

Making the Right Choice for Your Goal

To ensure your high-entropy alloy meets the necessary standards for application or research, apply the following principles:

- If your primary focus is establishing a research baseline: Ensure your process includes at least four remelting cycles with flipping to eliminate all macro-segregation and guarantee consistent microstructural evolution.

- If your primary focus is alloy purity: Prioritize a furnace capability that allows for high-vacuum pumping followed by ultra-pure argon backfilling to prevent oxidation of active elements like titanium and aluminum.

Ultimately, the uniformity of your high-entropy alloy is defined by the rigor of your mixing strategy; without sufficient remelting and stirring, you are producing a mixture, not an alloy.

Summary Table:

| Process Feature | Purpose in HEA Production | Key Benefit |

|---|---|---|

| Electromagnetic Stirring | Mixes elements with different densities | Eliminates macro-segregation |

| Multiple Remelting | Repeated flipping and melting (3-4x) | Ensures absolute chemical uniformity |

| Vacuum Environment | Protects active elements (Ti, Al, Cr) | Prevents oxidation and maintains purity |

| High-Temp Stability | Melts refractory metals (Mo, Nb) | Achieves full elemental diffusion |

Elevate Your Alloy Research with KINTEK

Don't let elemental segregation compromise your research integrity. KINTEK provides the precision equipment needed to achieve absolute chemical uniformity in high-entropy alloys.

Backed by expert R&D and manufacturing, we offer a comprehensive range of lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are customizable for your unique experimental requirements. Whether you are establishing a research baseline or scaling advanced material production, our team is ready to provide the technical expertise and high-performance furnaces you need.

Contact our experts today to find the perfect furnace for your lab!

Visual Guide

References

- Yukun Lv, Jian Chen. Improving Mechanical Properties of Co-Cr-Fe-Ni High Entropy Alloy via C and Mo Microalloying. DOI: 10.3390/ma17020529

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does VIM compare to DIM for LTES composites? Unlock Superior Thermal Storage and Stability

- What role do medium frequency induction furnaces play in heat treatment? Achieve Superior Metallurgical Properties

- What is the function of a high-temperature vacuum induction furnace in (Hf─Zr─Ti)C synthesis? Achieve 2100°C Precision

- What is the role of an IGBT transistor heating power supply in induction heating evaporation processes for magnesium powder? Master Precision Control for Superior Powder Quality

- What role does a vacuum induction melting furnace play in CoCrFeMnNi production? Ensure Purity and Homogeneity

- Why are higher frequencies needed in coreless induction furnaces for melting small loads of gold? Achieve Efficient Melting for Jewelry and Lab Samples

- How are current and voltage managed in the arc furnace process? Optimize Melting Efficiency and Stability

- What are five main applications of induction furnaces? Unlock Precision Melting for High-Value Metals