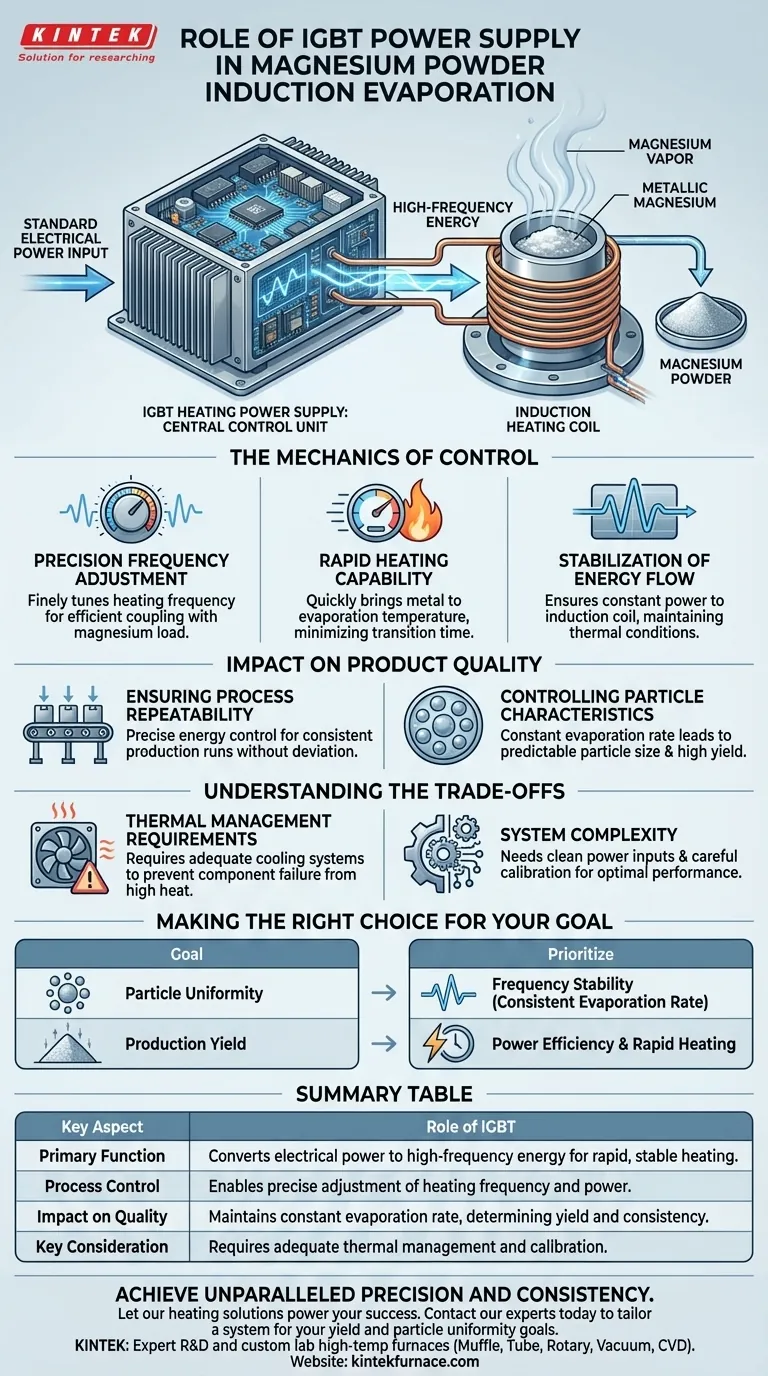

The IGBT (Insulated Gate Bipolar Transistor) heating power supply serves as the central control unit for the induction heating systems used to produce magnesium powder. Its primary function is to deliver precisely adjustable heating frequency and power, converting standard electrical power into the high-frequency energy needed to rapidly and stably heat metallic magnesium to its evaporation point.

By decoupling energy input from fluctuations in the grid or load, the IGBT power supply ensures a constant evaporation rate, which is the single most critical factor in determining the yield, particle size consistency, and overall quality of the magnesium powder.

The Mechanics of Control

Precision Frequency Adjustment

The IGBT power supply does not simply act as an on/off switch; it functions as a highly sophisticated tuner. It allows operators to adjust the heating frequency with extreme accuracy. This frequency control is essential for coupling the magnetic field efficiently with the magnesium load, ensuring energy is transferred exactly where it is needed.

Rapid Heating Capability

Efficiency in magnesium evaporation relies on speed. The IGBT supply facilitates quick heating, bringing the metal to the required temperature rapidly. This minimizes the time the material spends in transition states, optimizing the overall process cycle.

Stabilization of Energy Flow

Fluctuations in power can ruin a batch of powder. The IGBT system acts as a stabilizer, ensuring the power delivered to the induction coil remains constant. This stability is required to maintain the specific thermal conditions necessary for evaporation.

Impact on Product Quality

Ensuring Process Repeatability

In industrial manufacturing, the goal is to make every batch identical to the last. The precise energy control provided by the IGBT supply ensures consistency and repeatability. It removes variables from the heating equation, allowing you to replicate successful production runs without deviation.

Controlling Particle Characteristics

The characteristics of the final magnesium powder—specifically yield and particle size—are direct results of the evaporation rate. By maintaining a strictly controlled evaporation rate, the IGBT supply ensures the vapor density remains uniform, leading to predictable particle formation upon condensation.

Understanding the Trade-offs

Thermal Management Requirements

While IGBTs provide high efficiency, they switch high currents at high speeds, which generates significant internal heat. Adequate cooling systems are mandatory to protect the power supply itself. Failure to manage this heat can lead to component failure or thermal throttling, interrupting the evaporation process.

System Complexity

Implementing an IGBT-based system introduces a level of electronic complexity compared to older, less precise heating methods. This requires clean power inputs and careful calibration to ensure the frequency matches the induction coil and the load. Misalignment here can lead to inefficient heating despite the advanced hardware.

Making the Right Choice for Your Goal

To maximize the effectiveness of your magnesium powder production, align your power supply settings with your specific production targets:

- If your primary focus is Particle Uniformity: Prioritize frequency stability to ensure the evaporation rate never fluctuates, creating a consistent vapor density.

- If your primary focus is Production Yield: Prioritize power efficiency and rapid heating capabilities to maximize the amount of material evaporated per energy unit consumed.

The IGBT heating power supply is not just a power source; it is the quality control instrument that defines the standard of your final magnesium product.

Summary Table:

| Key Aspect | Role of IGBT Power Supply |

|---|---|

| Primary Function | Converts electrical power to high-frequency energy for rapid, stable heating. |

| Process Control | Enables precise adjustment of heating frequency and power for optimal energy transfer. |

| Impact on Quality | Maintains a constant evaporation rate, directly determining powder yield and particle size consistency. |

| Key Consideration | Requires adequate thermal management and system calibration for reliable operation. |

Achieve unparalleled precision and consistency in your magnesium powder production.

The advanced control offered by an IGBT power supply is critical for high-quality results. At KINTEK, we understand the intricate demands of induction heating processes. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Let our heating solutions power your success. Contact our experts today to discuss how we can tailor a system to meet your specific production goals for yield and particle uniformity.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

People Also Ask

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What are the applications of hot pressing? Achieve Maximum Material Performance