At its core, vacuum casting is a versatile manufacturing process used across a wide range of industries, including aerospace, medical, automotive, and consumer goods. It is chosen for its ability to produce highly detailed, high-fidelity parts in low volumes, from functional prototypes like automotive intake manifolds and aerospace air ducts to end-use products like medical implants and custom electronic enclosures.

The term "vacuum casting" actually refers to two distinct processes: one for creating detailed plastic parts using silicone molds and another for forging high-strength metal components in a furnace. Understanding which process aligns with your material and performance needs is the key to leveraging this technology effectively.

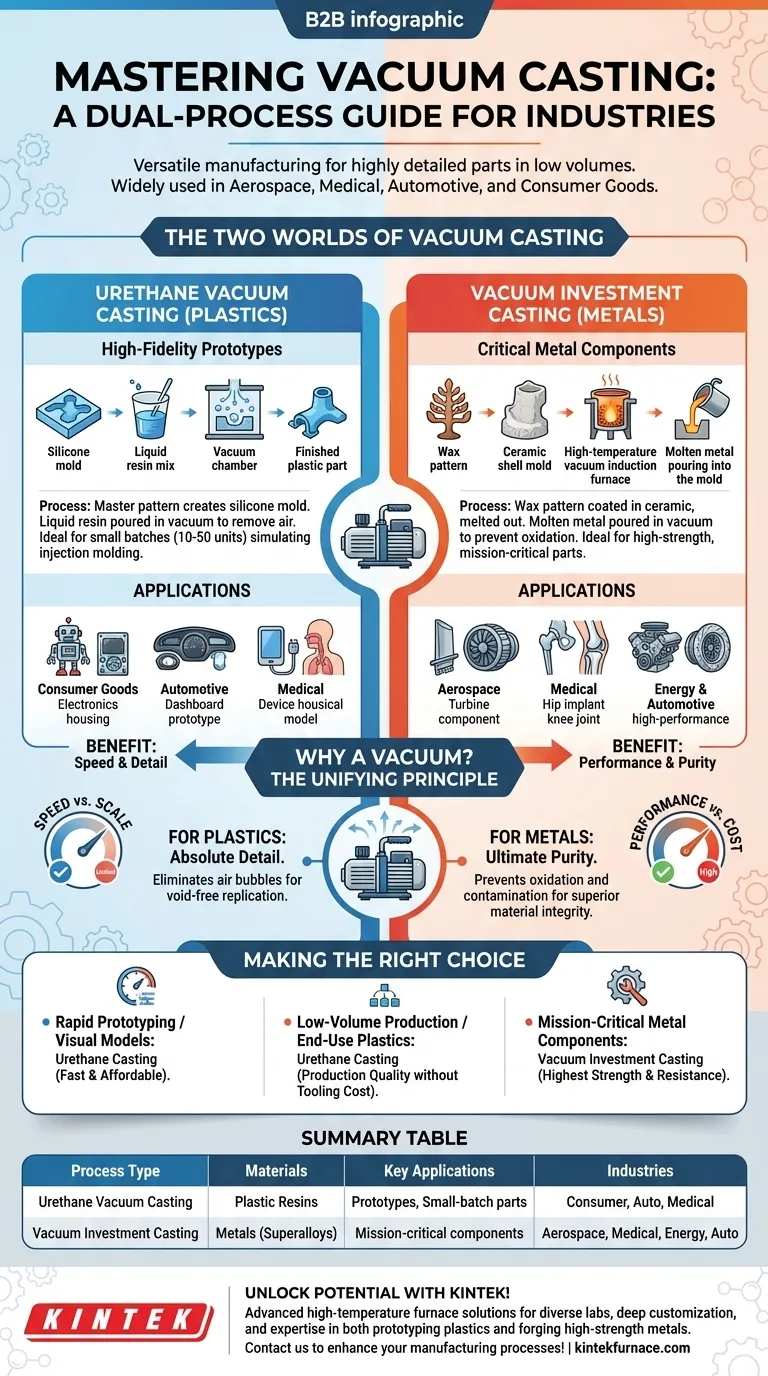

The Two Worlds of Vacuum Casting

The ambiguity in the term "vacuum casting" is the most common point of confusion. The core principle—using a vacuum to ensure quality—is the same, but the applications and materials are worlds apart.

Urethane Vacuum Casting: For High-Fidelity Prototypes

This process involves creating a master pattern (often 3D printed), which is then used to make a flexible silicone mold.

Liquid polyurethane resins are mixed and poured into this mold inside a vacuum chamber. The vacuum removes all air bubbles from the liquid resin, ensuring the final part is a perfect, void-free copy.

This method is ideal for producing small batches (typically 10-50 units) of plastic parts that closely simulate the look, feel, and function of injection-molded products.

Common applications include:

- Consumer Goods: Detailed prototypes for electronics, toys, and sporting equipment.

- Automotive: Pre-production evaluation parts like dashboards, interior trim, and light housings.

- Medical: Housings for medical devices and realistic anatomical models for surgical training.

Vacuum Investment Casting: For Critical Metal Components

This is a far more industrial process used for creating mission-critical metal parts, often from superalloys. It is sometimes called Vacuum Induction Melting (VIM).

Here, a wax pattern is coated in a ceramic slurry to create a hard mold. After the wax is melted out, molten metal is poured into the ceramic mold inside a high-temperature vacuum furnace.

The vacuum prevents the highly reactive molten metal from oxidizing or becoming contaminated by atmospheric gases, which would create weaknesses in the final part.

Common applications include:

- Aerospace: Turbine blades for jet engines, structural components, and fuel system parts that must withstand extreme temperatures and stress.

- Medical: High-strength, biocompatible implants like artificial knees and hips.

- Energy & Automotive: High-performance engine components and turbine parts for power generation.

Why a Vacuum? The Unifying Principle

Though the processes differ, the reason for using a vacuum environment is consistent: to eliminate imperfections caused by trapped gas.

For Plastics: Absolute Detail

In urethane casting, the vacuum’s role is to ensure fidelity. It pulls microscopic air bubbles out of the liquid resin, allowing the material to fill every tiny detail of the mold without voids or surface blemishes. The result is a perfect replication of the master pattern.

For Metals: Ultimate Purity

In investment casting, the vacuum’s role is to ensure material integrity. For high-performance alloys like nickel-based superalloys, any reaction with oxygen or nitrogen at high temperatures can be catastrophic, leading to impurities that compromise the part's strength and heat resistance. The vacuum provides a pure environment for casting.

Understanding the Trade-offs

Choosing the right process requires understanding its inherent limitations and benefits.

Urethane Casting: Speed vs. Scale

This process is incredibly fast for creating a small number of parts without the massive upfront cost of steel injection mold tooling.

However, the silicone molds have a limited lifespan (around 20-25 copies) and the per-part cost is higher than mass production methods. It is not economical for producing thousands of units.

Vacuum Investment Casting: Performance vs. Cost

This method produces metal parts with mechanical properties and reliability that are virtually impossible to achieve otherwise. It is the gold standard for components where failure is not an option.

This performance comes at a significant cost. Vacuum furnaces and the associated equipment are extremely expensive, and the process is complex and energy-intensive, making it suitable only for high-value applications.

Making the Right Choice for Your Application

Your project goals will dictate which version of "vacuum casting" is the correct path.

- If your primary focus is rapid prototyping and visual models: Urethane vacuum casting is your ideal choice for creating high-detail plastic parts quickly and affordably.

- If your primary focus is low-volume production of end-use plastic parts: Urethane casting provides production-quality finishes and material properties without the high cost of injection molding tooling.

- If your primary focus is producing mission-critical metal components: Vacuum investment casting is the necessary process for manufacturing parts with the highest possible strength, purity, and heat resistance.

Understanding this fundamental distinction empowers you to select the manufacturing process that precisely matches your project's material, budget, and performance requirements.

Summary Table:

| Process Type | Materials | Key Applications | Industries |

|---|---|---|---|

| Urethane Vacuum Casting | Plastic resins (e.g., polyurethane) | Prototypes, small-batch parts | Consumer goods, automotive, medical |

| Vacuum Investment Casting | Metals (e.g., superalloys) | Mission-critical components | Aerospace, medical, energy, automotive |

Unlock the full potential of vacuum casting for your projects with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet unique experimental requirements. Whether you're prototyping with plastics or forging high-strength metals, our expertise ensures superior results. Contact us today to discuss how we can enhance your manufacturing processes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors