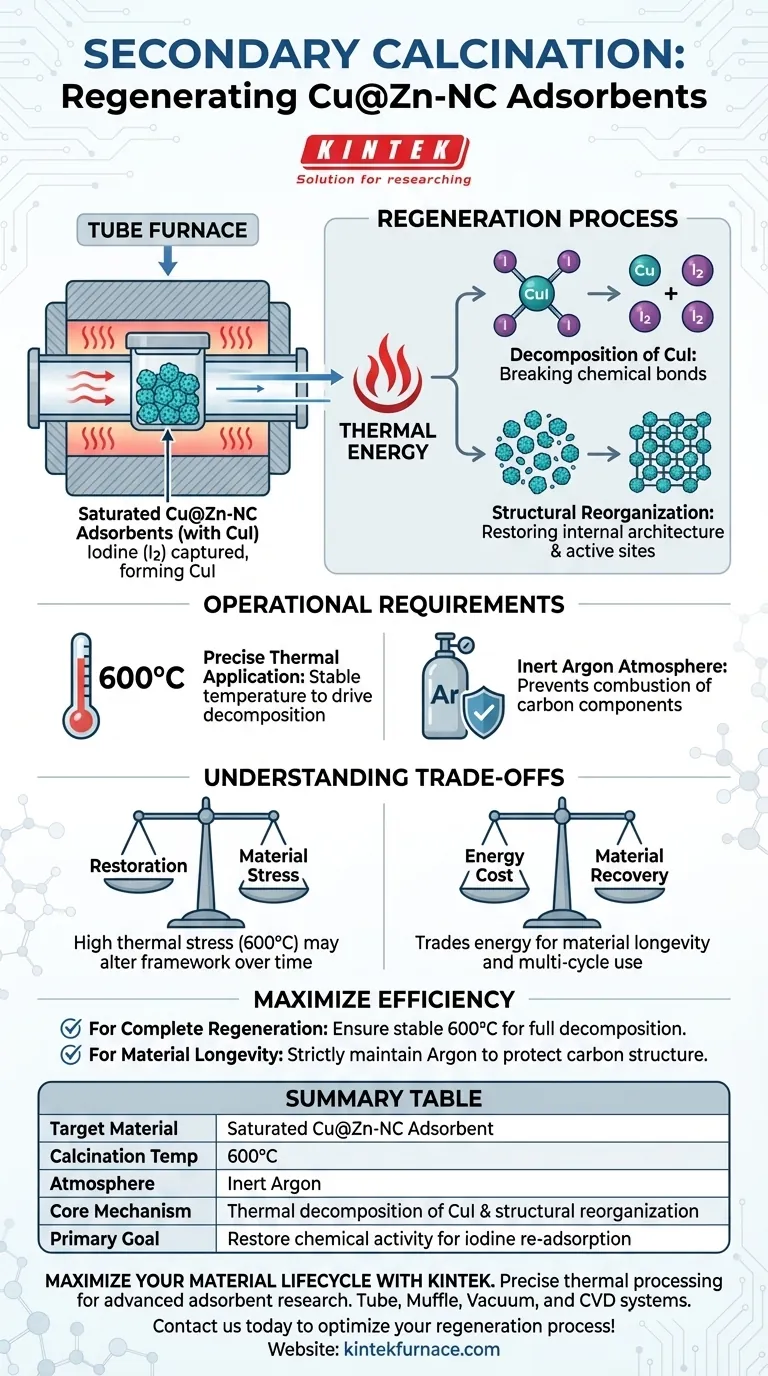

The primary function of secondary calcination is to regenerate the chemical activity of Cu@Zn-NC adsorbents after they have been saturated with iodine. Carried out in a tube furnace at 600°C under an argon atmosphere, this process uses thermal energy to decompose or structurally reorganize the copper iodide (CuI) formed during capture, effectively resetting the material's active sites for reuse.

Regeneration is the key to maximizing the lifecycle of an adsorbent. Secondary calcination leverages precise thermal control to reverse the chemical binding of iodine, transforming a single-use material into a sustainable, multi-cycle solution.

The Mechanism of Regeneration

Targeting the Iodine Bond

During the initial adsorption phase, the material captures iodine, resulting in the formation of loaded copper iodide (CuI).

To use the material again, these chemical bonds must be broken. Secondary calcination provides the necessary energy to induce the decomposition of this CuI.

Structural Reorganization

Beyond simple decomposition, the heat treatment facilitates a structural reorganization of the material.

This reorganization attempts to restore the internal architecture of the adsorbent, ensuring that the active sites are physically accessible for the next cycle of iodine capture.

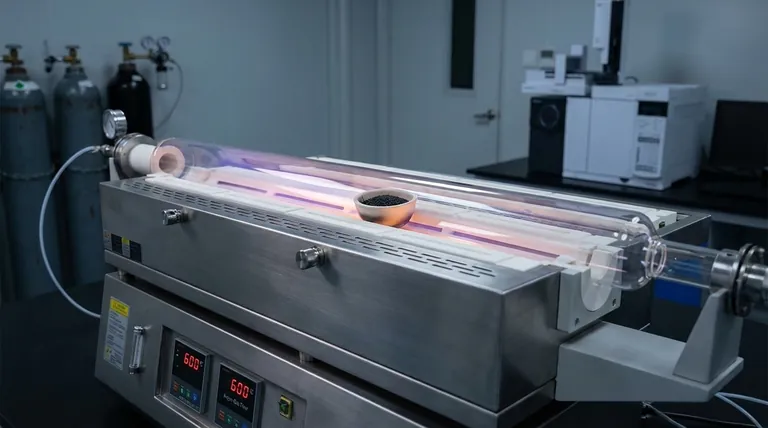

Operational Requirements

Precise Thermal Application

The process requires a specific temperature of 600 degrees Celsius.

A tube furnace is utilized because it can maintain this high temperature with the stability required to drive the decomposition process without destroying the base material.

Controlled Atmosphere

The calcination must occur under an argon atmosphere.

Using an inert gas like argon is critical to prevent unwanted reactions, such as the combustion of the carbon-based components of the composite, which would occur if oxygen were present.

Understanding the Trade-offs

Material Stress and Alteration

While the goal is restoration, the primary reference notes that the process induces structural reorganization.

Repeated exposure to high thermal stress (600°C) may eventually alter the material's framework. It is crucial to monitor the adsorbent to ensure that "reorganization" does not degrade into "deterioration" over many cycles.

Energy vs. Material Recovery

This process trades thermal energy for material longevity.

You must balance the energy cost of running a tube furnace at 600°C against the cost of manufacturing fresh adsorbent. This step is vital for evaluating the material's performance over multiple reuse cycles.

Making the Right Choice for Your Goal

To maximize the efficiency of your regeneration process, consider these priorities:

- If your primary focus is complete regeneration: Ensure the furnace maintains a stable 600°C to fully induce the decomposition of loaded CuI.

- If your primary focus is material longevity: Strictly maintain the argon atmosphere to protect the carbon structure from oxidative damage during heating.

The tube furnace is not just a heater; it is the critical tool for validating the reusability and economic potential of your carbon-based composite materials.

Summary Table:

| Feature | Regeneration Requirement |

|---|---|

| Target Material | Saturated Cu@Zn-NC Adsorbent |

| Calcination Temp | 600°C |

| Atmosphere | Inert Argon (prevents carbon combustion) |

| Core Mechanism | Thermal decomposition of CuI & structural reorganization |

| Primary Goal | Restore chemical activity for iodine re-adsorption |

Maximize Your Material Lifecycle with KINTEK

Precise thermal processing is the difference between successful regeneration and material failure. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Vacuum, and CVD systems designed to maintain the strict 600°C stability and inert environments required for advanced adsorbent research.

Whether you need a standard solution or a custom furnace tailored to your unique lab requirements, our team is ready to support your sustainability goals. Contact us today to optimize your regeneration process!

Visual Guide

References

- Jiuyu Chen, Zhiwen Liu. Cu0-Functionalized, ZIF-8-Derived, Nitrogen-Doped Carbon Composites for Efficient Iodine Elimination in Solution. DOI: 10.3390/nano15020105

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a tube furnace play in the preparation of biochar-filled PVC composite precursors? Expert Synthesis Guide

- How does a tube furnace facilitate the transformation of natural wood into a Carbonized Wood carrier? Master Pyrolysis

- Why do we use a tubular furnace? For Unmatched Temperature Uniformity and Atmospheric Control

- How does a high-temperature tube furnace facilitate HfOC/SiOC pyrolysis? Mastering Polymer-to-Ceramic Transition

- What role does a tube furnace play in the high-temperature modification of La-EPS-C-450? Key Synthesis Insights

- Why is pre-oxidation treatment of the substrate in a tube furnace necessary? Ensure Strong Ti(Nb)-Si-C Coating Adhesion

- What role does a vacuum tube furnace play in AlCrSiWN coating annealing? Enhance Stability and Hardness

- How does a high-temperature tube atmosphere furnace contribute to nitrogen-doping of graphene oxide? Enhance Your R&D