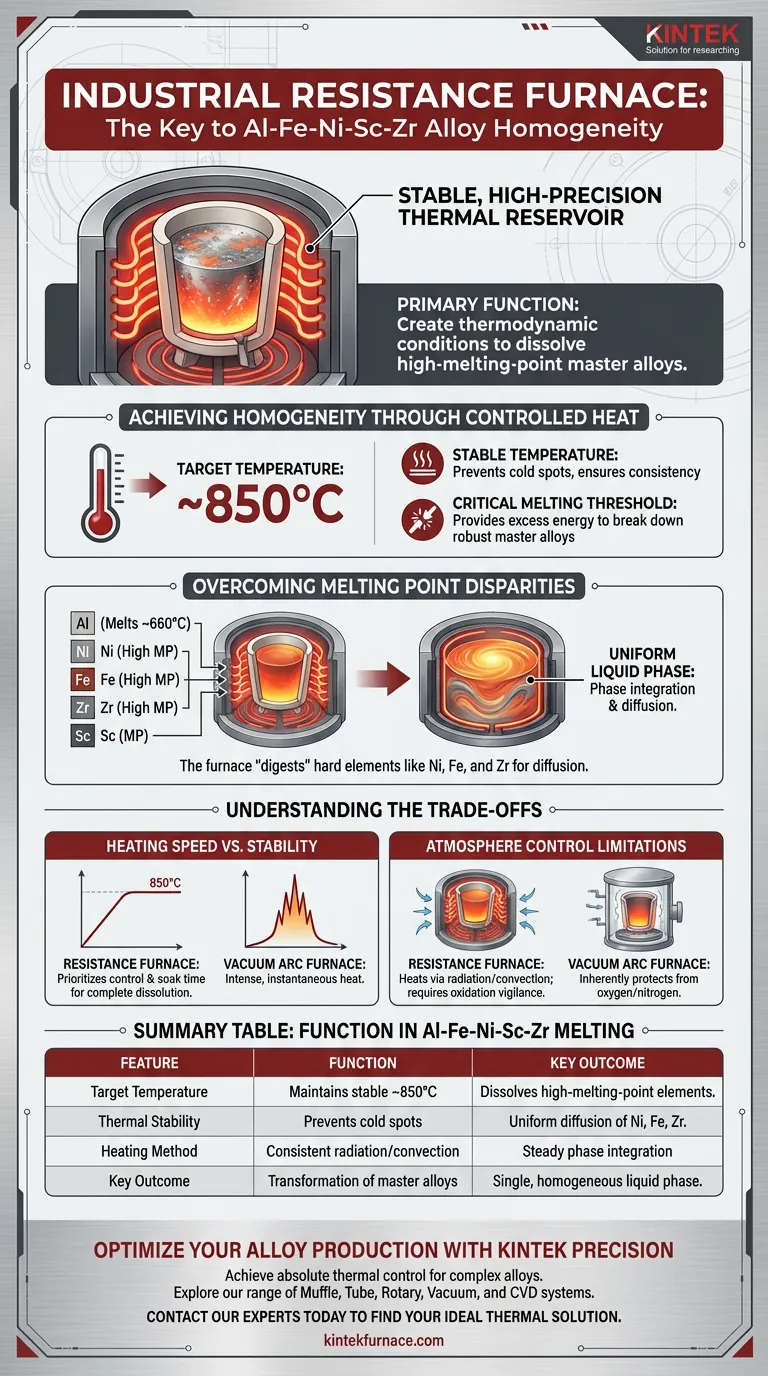

The primary function of an industrial resistance furnace in the production of Al-Fe-Ni-Sc-Zr alloys is to serve as a stable, high-precision thermal reservoir. Its specific role is to elevate the aluminum melt to a target temperature of roughly 850°C, creating the thermodynamic conditions necessary to fully dissolve high-melting-point master alloys.

Core Takeaway While simple melting requires heat, creating complex alloys requires thermal equilibrium. The industrial resistance furnace is essential because it maintains the steady, high-temperature environment needed to force refractory elements like Nickel, Iron, and Zirconium to dissolve completely into the liquid Aluminum phase without segregating.

Achieving Homogeneity Through Controlled Heat

The Role of Stable Temperature

Unlike equipment designed for rapid, aggressive melting (such as electric arcs), an industrial resistance furnace is designed for consistency. It provides a steady heat source that envelops the crucible.

This stability is critical for Al-Fe-Ni-Sc-Zr alloys. It prevents "cold spots" in the melt where heavier elements might solidify or precipitate out of the solution prematurely.

Reaching the Critical Melting Threshold

The furnace is tasked with reaching and maintaining a specific target temperature, typically 850°C.

While pure aluminum melts at a much lower temperature (approx. 660°C), this higher target is non-negotiable. It provides the excess thermal energy required to break down the bonds of the more robust master alloys added to the mix.

Overcoming Melting Point Disparities

Dissolving High-Melting-Point Master Alloys

The central challenge in creating this alloy is that components like Nickel, Iron, and Zirconium have melting points far higher than Aluminum.

If you simply melted the Aluminum and added these elements, they might remain as solid inclusions. The resistance furnace uses its high operating temperature to facilitate diffusion, effectively "digesting" these harder elements into the mix.

Ensuring a Uniform Liquid Phase

The ultimate goal of this heating process is phase integration. The furnace ensures that all distinct metallic components transition into a single, homogeneous liquid phase.

This uniformity is vital. If the furnace fails to maintain 850°C, the alloy may suffer from segregation, where the Iron or Nickel clusters together rather than dispersing evenly throughout the Aluminum matrix.

Understanding the Trade-offs

Heating Speed vs. Stability

Resistance furnaces prioritize control over speed. They do not generate the intense, instantaneous heat of a vacuum arc furnace (often used for Titanium alloys).

Consequently, the process requires patience. The "soak time" at 850°C is a feature, not a bug, ensuring complete dissolution rather than rapid liquefaction.

Atmosphere Control Limitations

Unlike vacuum arc furnaces, which inherently protect reactive metals from oxygen and nitrogen via a vacuum environment, a standard resistance furnace heats via radiation and convection.

This means that while the temperature is perfect for melting Al-Fe-Ni-Sc-Zr, operators must be vigilant about oxidation. The stability of the resistance furnace allows for a calm surface, but it does not actively strip away oxygen like a vacuum system would.

Making the Right Choice for Your Goal

To maximize the effectiveness of the industrial resistance furnace in this process, focus on these operational priorities:

- If your primary focus is Alloy Homogeneity: Ensure the furnace holds the melt at 850°C for sufficient time to allow full diffusion of Iron and Zirconium master alloys.

- If your primary focus is Process Efficiency: Pre-calculate the exact thermal load of your master alloys to minimize the time the furnace needs to recover to the target temperature after additions.

Success in this process is defined not just by melting the metal, but by sustaining the precise thermal environment required for complex integration.

Summary Table:

| Feature | Function in Al-Fe-Ni-Sc-Zr Melting |

|---|---|

| Target Temperature | Maintains a stable ~850°C to dissolve high-melting-point elements |

| Thermal Stability | Prevents cold spots to ensure uniform diffusion of Ni, Fe, and Zr |

| Heating Method | Consistent radiation/convection for steady phase integration |

| Key Outcome | Transformation of master alloys into a single, homogeneous liquid phase |

Optimize Your Alloy Production with KINTEK Precision

Achieving perfect homogeneity in complex Al-Fe-Ni-Sc-Zr alloys requires more than just heat—it requires absolute thermal control. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the most demanding lab and industrial applications.

Whether you need a high-precision resistance furnace or a fully customizable high-temperature system tailored to your unique metallurgy needs, our team is ready to help you eliminate segregation and improve material performance.

Ready to elevate your melting process? Contact our experts today to find the ideal thermal solution for your lab.

Visual Guide

References

- Mingliang Wang, Haowei Wang. Optimizing the Heat Treatment Method to Improve the Aging Response of Al-Fe-Ni-Sc-Zr Alloys. DOI: 10.3390/ma17081772

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is an atmosphere furnace? Achieve Superior Material Processing with Controlled Environments

- What advantages does an inert oven provide? Achieve Precise Control for Sensitive Materials

- How do nitrogen and air atmospheres affect coke evolution? Optimize High-Temp Carbon Treatment Outcomes

- What is the function of a tube atmosphere furnace? Precision Mn1/CeO2 Catalyst Reduction & Fabrication

- Why is a nitrogen environment necessary for Cu13Se52Bi35 thin film annealing? Protect Your Material Purity

- Why are retort furnaces significant in industrial applications? Unlock Precision Heat Treatment and Superior Material Quality

- What is the primary function of an air oxidation furnace in carbon chain synthesis? Optimize SWCNT Pretreatment

- What is the purpose of steam atmosphere in furnace applications? Enhance Metal Durability with Controlled Oxidation