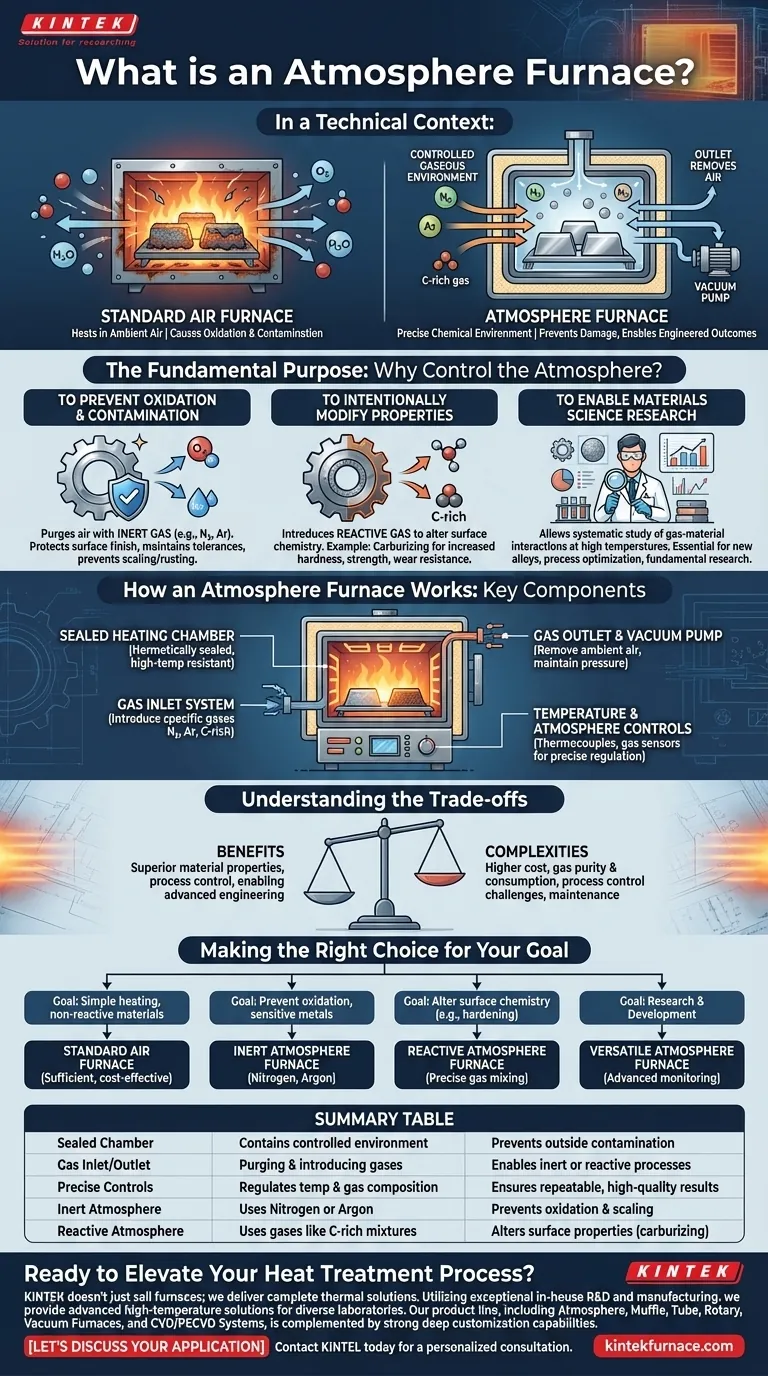

In a technical context, an atmosphere furnace is a specialized piece of equipment that heats materials within a tightly controlled gaseous environment. Unlike a standard furnace that operates in ambient air, an atmosphere furnace allows operators to replace the air with specific gases—either inert or reactive—to prevent unwanted chemical reactions like oxidation or to intentionally alter the material's surface properties during the heating process.

The core purpose of an atmosphere furnace is not just to heat a material, but to precisely manage the chemical environment while it is hot. This control is critical for preventing damage and achieving specific, engineered outcomes in the final product.

The Fundamental Purpose: Why Control the Atmosphere?

At high temperatures, the oxygen and moisture in normal air become highly reactive with most materials. An atmosphere furnace is designed to solve this problem and unlock new processing capabilities.

To Prevent Oxidation and Contamination

The most common reason to use an atmosphere furnace is to prevent oxidation. When heated, metals like steel or copper will rapidly react with oxygen to form oxides—a process commonly known as scaling or, in a slower form, rusting.

This oxidation can ruin surface finishes, alter dimensional tolerances, and weaken the material. By purging the air and replacing it with an inert gas like nitrogen or argon, the furnace creates a protective environment where the material can be heated without reacting.

To Intentionally Modify Material Properties

The furnace atmosphere is not always passive. In some processes, a specific reactive gas is introduced to intentionally change the chemical composition of the material's surface.

For example, in a process called carburizing, carbon-rich gases are used to increase the surface hardness of steel parts. The controlled atmosphere becomes an active ingredient in the heat-treatment process, allowing engineers to tailor a material's final properties like strength and wear resistance.

To Enable Materials Science Research

In research and development, atmosphere furnaces are invaluable tools. They allow scientists to systematically study how different gaseous environments affect materials at high temperatures.

This capability is essential for developing new alloys, optimizing manufacturing processes, and understanding fundamental material behaviors under extreme conditions.

How an Atmosphere Furnace Works: Key Components

The ability to maintain a pristine, controlled environment relies on a few critical systems working in concert.

The Sealed Heating Chamber

The core of the furnace is a chamber built from high-temperature-resistant materials. Crucially, this chamber must be hermetically sealed with gaskets or welded joints to prevent outside air from leaking in and contaminating the internal atmosphere.

The Gas Inlet and Outlet System

A sophisticated system of pipes, valves, and flow controllers manages the gases inside the chamber. An inlet introduces the desired gas (e.g., nitrogen, argon), while an outlet, often connected to a vacuum pump, is used to first remove the ambient air. This system maintains the correct pressure and gas composition throughout the heating cycle.

Temperature and Atmosphere Control Systems

Thermocouples constantly measure the internal temperature, feeding data to a controller that regulates the heating elements. Simultaneously, sensors may analyze the gas composition to ensure it remains within the specified parameters, allowing for precise and repeatable results.

Understanding the Trade-offs

While powerful, atmosphere furnaces introduce complexities not found in simpler air-based furnaces.

Higher Cost and Complexity

The need for a sealed chamber, gas delivery systems, vacuum pumps, and advanced control instrumentation makes these furnaces significantly more expensive to purchase and operate.

Gas Purity and Consumption

The process relies on a constant supply of high-purity gas, which represents a significant operational cost. Any impurities in the gas supply can compromise the entire process, leading to rejected parts.

Process Control Challenges

Maintaining a perfect seal and a consistent gas mixture at extreme temperatures is a technical challenge. It requires careful operation, rigorous maintenance, and a deep understanding of the process parameters to avoid costly failures.

Making the Right Choice for Your Goal

Selecting the correct heating technology depends entirely on your material and desired outcome.

- If your primary focus is simple heating of non-reactive materials: A standard air furnace is often sufficient, simpler, and more cost-effective.

- If your primary focus is preventing oxidation on sensitive metals: An inert atmosphere furnace using nitrogen or argon is non-negotiable to protect the material's surface and integrity.

- If your primary focus is altering the surface chemistry of a part (e.g., hardening steel): A reactive atmosphere furnace with precise gas-mixing capabilities is required.

- If your primary focus is research and development: A versatile atmosphere furnace with advanced monitoring is essential for exploring new material properties.

Ultimately, choosing to use an atmosphere furnace is a decision to invest in process control to achieve superior material properties.

Summary Table:

| Feature | Purpose | Key Benefit |

|---|---|---|

| Sealed Chamber | Contains controlled gas environment | Prevents contamination from outside air |

| Gas Inlet/Outlet | Purging air & introducing specific gases | Enables inert (N2, Ar) or reactive processes |

| Precise Controls | Regulates temperature & gas composition | Ensures repeatable, high-quality results |

| Inert Atmosphere | Uses nitrogen or argon | Prevents oxidation & scaling on metals |

| Reactive Atmosphere | Uses gases like carbon-rich mixtures | Alters surface properties (e.g., carburizing) |

Ready to Elevate Your Heat Treatment Process?

An atmosphere furnace is the key to unlocking superior material properties, from preventing oxidation to enabling advanced surface engineering. But achieving these results requires a furnace tailored to your specific materials and process goals.

KINTEK doesn't just sell furnaces; we deliver complete thermal solutions. Leveraging our exceptional in-house R&D and manufacturing capabilities, we provide advanced high-temperature furnace solutions for diverse laboratories. Our product line, including Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Let's discuss your application. Our experts will help you determine the ideal atmosphere and furnace configuration to achieve your desired outcomes, whether you're in R&D or production.

Contact KINTEL today for a personalized consultation and discover how our expertise can transform your material processing.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening