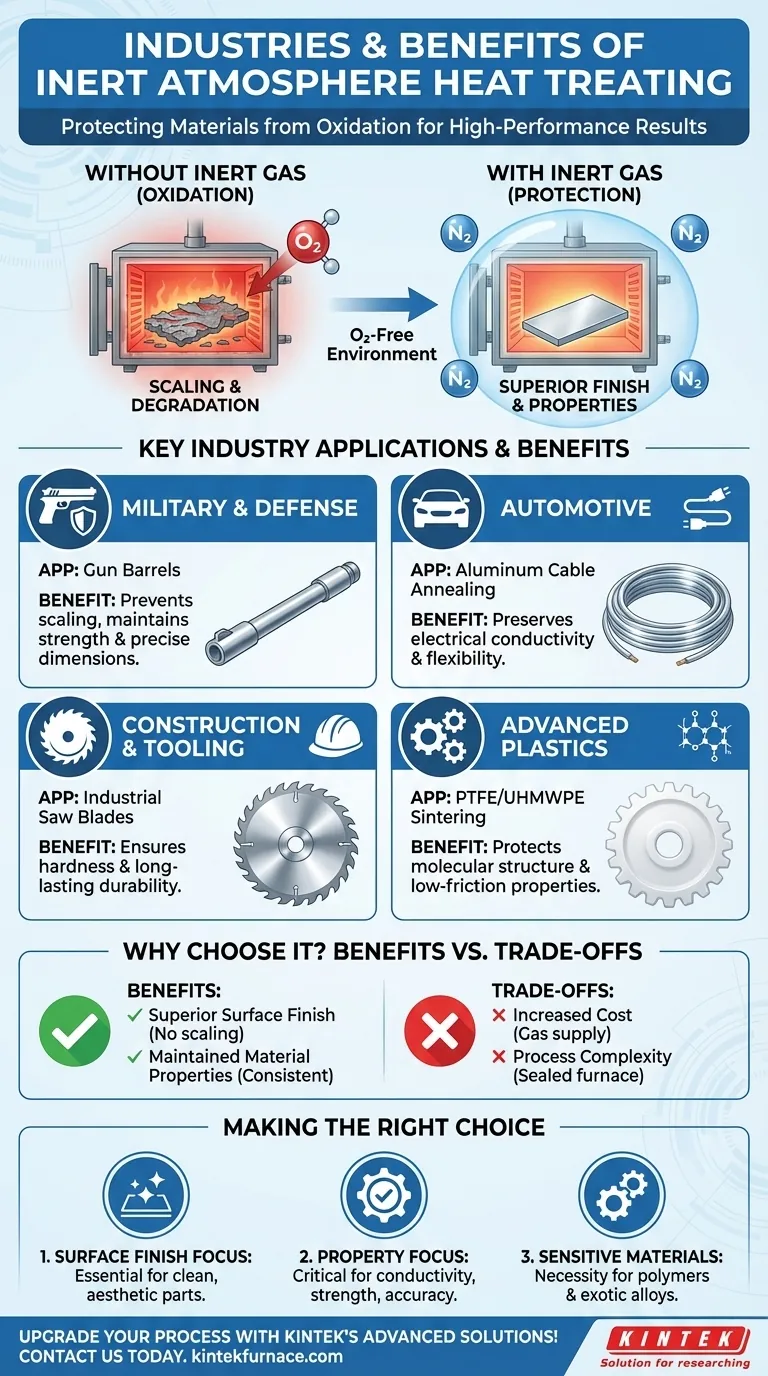

In short, inert atmosphere heat treating is used by the military, automotive, construction, and advanced plastics industries. Its primary purpose is to heat materials in an oxygen-free environment, which prevents destructive chemical reactions like oxidation and preserves the material's original quality and performance characteristics.

The core principle is simple: heating a material in normal air can ruin it. Inert atmosphere heat treating protects a material's surface finish and internal properties by replacing reactive oxygen with a neutral gas like nitrogen during the heating process.

What is Inert Atmosphere Heat Treating?

Heat treatment is a foundational manufacturing process, but it has a fundamental vulnerability. When most materials are heated in the presence of oxygen, they react, often to their detriment. Inert atmosphere heat treating directly solves this problem.

The Problem: Oxidation at High Temperatures

Heating materials in ambient air exposes them to oxygen, leading to oxidation. This chemical reaction can be highly destructive.

For metals like steel, oxidation causes scaling—a flaky, brittle surface layer that ruins the finish and can compromise the part's dimensions and strength. This process begins at temperatures as low as 450°F (232°C).

For other materials, like certain polymers, oxygen exposure during heating can degrade their molecular structure, permanently damaging their unique properties.

The Solution: A Controlled, Inert Environment

This process involves heating parts inside a sealed furnace or oven that has been purged of oxygen.

First, an inert gas—most commonly nitrogen—is used to flush out the oxygen-rich air. Once oxygen levels are sufficiently low, the heating cycle begins. This protective "blanket" of inert gas is maintained throughout the heating and cooling phases, ensuring the material is never exposed to oxygen while it is vulnerable.

Key Industry Applications

Different industries leverage this process to solve specific material challenges, protecting their investment in high-performance components.

Military & Personal Defense

In manufacturing components like gun barrels, maintaining precise dimensions and material strength is non-negotiable. Inert atmosphere treatment prevents surface scaling on steel, ensuring the barrel's integrity and performance without the need for costly post-treatment grinding or polishing.

Automotive

The automotive industry uses a wide range of materials that require precise properties. During the annealing of aluminum electrical cables, an inert atmosphere prevents surface oxidation that would otherwise reduce electrical conductivity and compromise flexibility.

Construction & Tooling

For tools that rely on hardness and sharpness, like industrial saw blades, oxidation during heat treatment can create a brittle, weak surface. Using an inert atmosphere preserves the steel's intended hardness and durability, leading to a longer-lasting and more reliable tool.

Advanced Plastics

Specialty polymers like PTFE (Teflon) and UHMW polyethylene are known for their extremely low-friction surfaces. However, these plastics are easily damaged by oxygen when heated. Processes like sintering, which fuses powdered plastic into a solid form, must be done in an inert atmosphere to preserve the polymer's molecular structure and unique properties.

Understanding the Benefits and Trade-offs

While highly effective, the decision to use this process involves weighing its distinct advantages against its inherent complexity.

Benefit: Superior Surface Finish

The most obvious advantage is the prevention of oxidation, scaling, and discoloration. This delivers a clean, bright surface finish directly out of the furnace, often eliminating the need for secondary cleaning or polishing operations.

Benefit: Maintained Material Properties

By preventing unwanted chemical reactions, the process ensures the material's core mechanical, electrical, and chemical properties remain unchanged. The material you put in is the material you get out, only with its microstructure altered as intended.

The Trade-off: Cost and Complexity

The primary trade-off is increased cost and process complexity. Operating a sealed furnace and paying for a continuous supply of inert gas like nitrogen is more expensive than heating parts in an open-air oven. This makes the process best suited for applications where material integrity and surface quality are critical requirements.

Making the Right Choice for Your Goal

Deciding whether to specify inert atmosphere treatment depends entirely on the required outcome for your component.

- If your primary focus is surface finish and aesthetics: This process is essential for creating clean, scale-free parts that do not require post-treatment polishing.

- If your primary focus is preserving precise properties: For components where electrical conductivity, material strength, or dimensional accuracy is critical, an inert atmosphere is your only reliable option.

- If your primary focus is processing sensitive materials: For oxygen-sensitive polymers or exotic alloys, inert atmosphere treatment is not a choice but a necessity.

Ultimately, understanding that heat and oxygen are often enemies is the key to selecting the correct manufacturing process.

Summary Table:

| Industry | Key Applications | Benefits |

|---|---|---|

| Military & Personal Defense | Gun barrels | Prevents scaling, maintains strength and dimensions |

| Automotive | Annealing of aluminum electrical cables | Preserves conductivity and flexibility |

| Construction & Tooling | Industrial saw blades | Ensures hardness and durability |

| Advanced Plastics | Sintering of PTFE and UHMW polyethylene | Protects molecular structure and low-friction properties |

Upgrade your heat treatment process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance material integrity and efficiency in your industry!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance