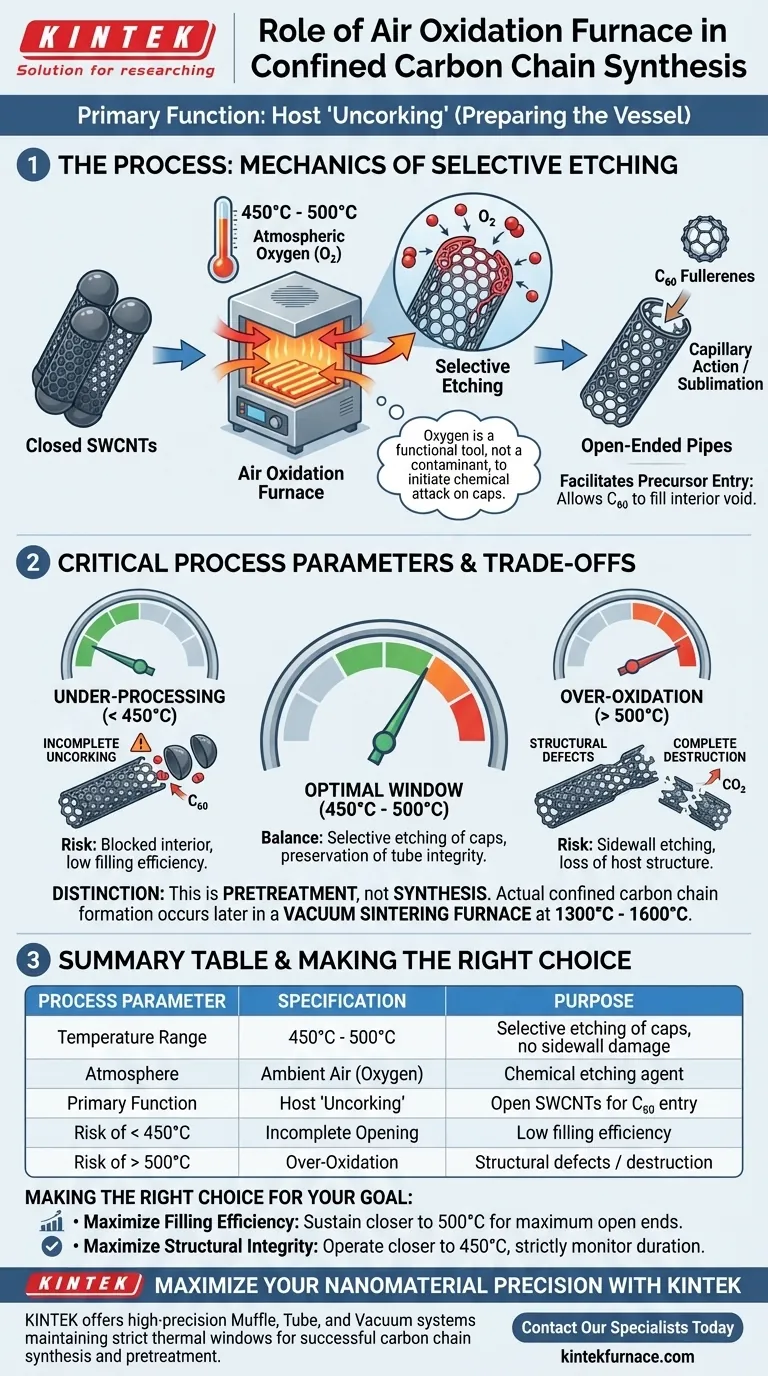

The primary function of an air oxidation furnace in the synthesis pretreatment of confined carbon chains is to mechanically open the host structure. By heating single-walled carbon nanotubes (SWCNTs) to a specific temperature range of 450°C to 500°C, the furnace utilizes atmospheric oxygen to selectively etch away the closed caps at the ends of the tubes. This "uncorking" process is the fundamental prerequisite for encapsulating precursor molecules.

Core Takeaway An air oxidation furnace does not synthesize the carbon chains itself; it prepares the vessel. Its sole purpose in this phase is the controlled removal of nanotube end-caps to allow precursor materials, such as C60 fullerenes, to access and fill the interior void.

The Mechanics of Selective Etching

Opening the Host Structure

Single-walled carbon nanotubes are naturally synthesized as closed cylinders. To use them as containers for confined carbon chains, you must first create a physical opening.

The air oxidation furnace leverages the chemical reactivity of the nanotube caps. Because the carbon atoms at the curved ends (caps) are under higher strain than those along the straight sidewalls, they are more susceptible to oxidation.

The Role of Oxygen

In this specific pretreatment phase, oxygen is a functional tool, not a contaminant. The furnace introduces air to the heated nanotubes to initiate a chemical attack on the carbon structure.

This reaction effectively burns off the caps, converting the closed tubes into open-ended pipes ready for filling.

Facilitating Precursor Entry

Once the caps are removed, the interior channel of the nanotube becomes accessible.

This allows precursor molecules—specifically C60 fullerenes—to enter the nanotube via capillary action or sublimation. Without this oxidation step, the precursors would remain on the exterior, making the synthesis of confined chains impossible.

Critical Process Parameters

The Temperature Window

The success of this pretreatment relies entirely on thermal precision. The primary reference identifies the operational window as 450°C to 500°C.

This range is specific to the oxidative stability of single-walled carbon nanotubes. It provides enough energy to drive the etching reaction at the caps without destroying the tubular structure.

Distinguishing Pretreatment from Synthesis

It is vital to distinguish this air oxidation step from the actual high-temperature synthesis that follows.

While the air furnace operates at moderate temperatures (up to 500°C) to open the tubes, the actual formation and structural rearrangement of the confined carbon chains occur later. That subsequent step typically requires a vacuum sintering furnace operating between 1300°C and 1600°C to drive the conversion of precursors.

Understanding the Trade-offs

The Risk of Over-Oxidation

The most significant risk when using an air oxidation furnace is exceeding the 500°C upper limit.

If the temperature is too high, the oxygen will cease to be selective. It will begin to etch the sidewalls of the nanotubes, creating defects or burning the nanotubes entirely into carbon dioxide.

The Consequence of Under-Processing

Conversely, operating below 450°C may result in incomplete uncorking.

If the caps are not fully removed, the filling efficiency drops drastically because the precursors are physically blocked from entering the confinement space.

Making the Right Choice for Your Goal

To ensure the successful synthesis of confined carbon chains, you must view the air oxidation furnace as a precision preparation tool rather than a reactor.

- If your primary focus is maximizing filling efficiency: Ensure your furnace sustains a temperature closer to the 500°C limit to guarantee the maximum number of nanotube ends are opened.

- If your primary focus is structural integrity: Operate closer to 450°C and strictly monitor the duration to prevent sidewall damage, ensuring the host tubes remain robust for the subsequent high-temperature sintering phase.

The air oxidation furnace balances the destruction of the cap with the preservation of the tube, creating the gateway for advanced carbon synthesis.

Summary Table:

| Process Parameter | Specification | Purpose in Synthesis |

|---|---|---|

| Temperature Range | 450°C - 500°C | Selective etching of nanotube caps without damaging sidewalls |

| Atmosphere | Ambient Air (Oxygen) | Acts as the chemical etching agent for the carbon structure |

| Primary Function | Host "Uncorking" | Opening closed SWCNTs to allow C60 fullerene entry |

| Risk of < 450°C | Incomplete Opening | Blocked interior voids leading to low filling efficiency |

| Risk of > 500°C | Over-Oxidation | Structural defects or complete destruction of the nanotubes |

Maximize Your Nanomaterial Precision with KINTEK

Successful carbon chain synthesis begins with flawless pretreatment. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, and Vacuum systems designed to maintain the strict 450°C-500°C thermal windows required for SWCNT oxidation.

Whether you need an air oxidation furnace for uncorking or a high-temperature vacuum sintering furnace (up to 1600°C) for final conversion, our lab equipment is fully customizable for your unique research needs.

Ready to achieve superior filling efficiency? Contact our technical specialists today to find the perfect thermal solution for your laboratory.

Visual Guide

References

- Clara Freytag, Thomas Pichler. Systematic Optimization of the Synthesis of Confined Carbyne. DOI: 10.1002/smtd.202500075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is inert atmosphere heat treating important for steel? Prevent Oxidation for Superior Finish and Performance

- What gases are introduced into the box type annealing atmosphere furnace? Optimize Your Heat Treatment Process

- What advantages does the box type annealing atmosphere furnace offer? Achieve Superior Heat Treatment Control

- What high-temperature processes commonly use argon in furnaces? Essential Guide for Reactive Metals

- What factors need adjusting in an atmosphere protection muffle furnace? Optimize for Process Control and Safety

- What are the key features of calcining furnaces? Boost Efficiency and Quality in Material Processing

- In what settings are controlled atmosphere furnaces commonly used? Essential for High-Purity Material Processing

- Why are sealing mechanisms critical in atmosphere furnaces? Ensure Purity, Safety, and Efficiency