In short, a box-type annealing atmosphere furnace offers significant advantages in process control, efficiency, and operational safety. It excels at delivering precise, repeatable heat treatment by combining accurate atmosphere management with uniform temperature distribution, leading to superior material properties and reduced cycle times.

The core value of this furnace is not just one feature, but the integration of multiple systems. It provides a tightly controlled environment that ensures the final material meets exact specifications, making it a reliable tool for high-stakes manufacturing and research.

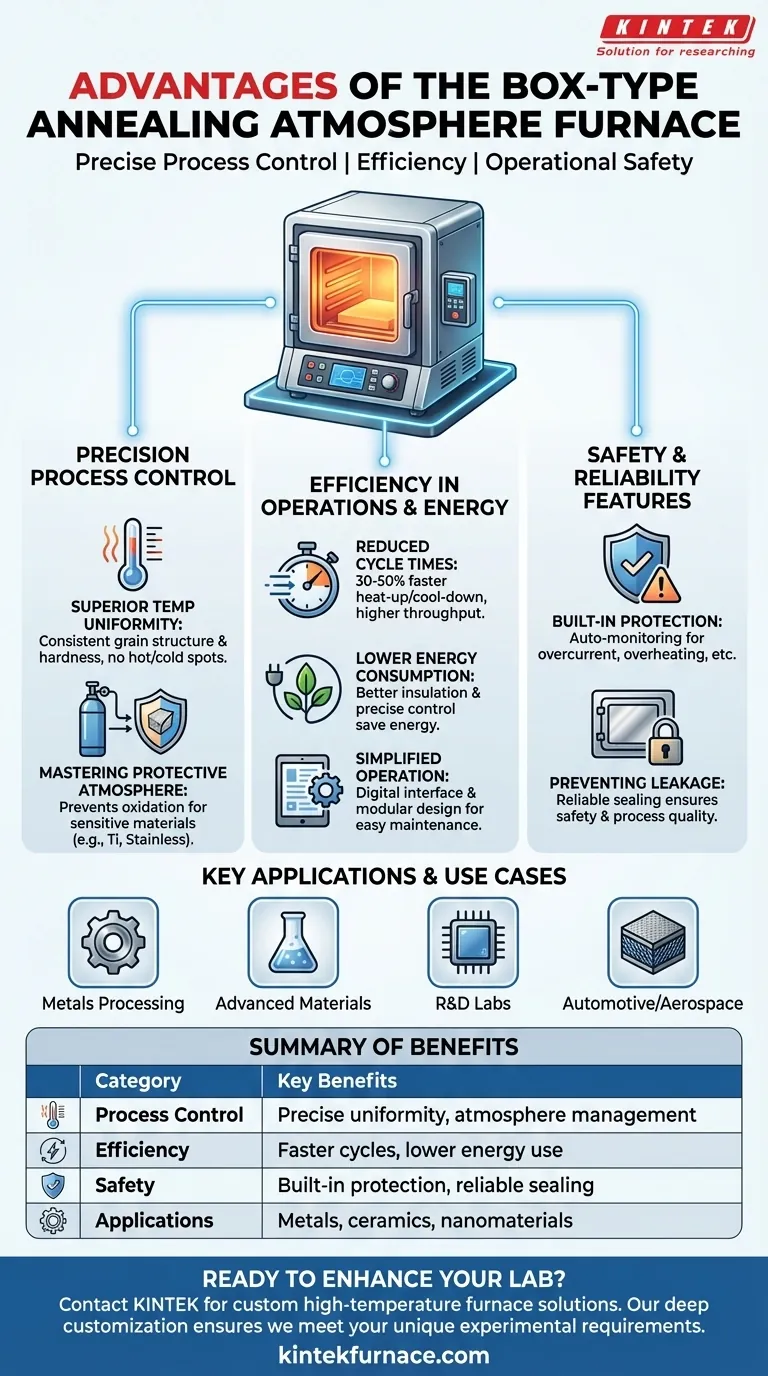

The Foundation: Precision Process Control

The primary goal of annealing is to alter a material's microstructure to achieve desired properties. A box-type atmosphere furnace provides the two most critical levers for this process: temperature and atmosphere.

Achieving Superior Temperature Uniformity

These furnaces are engineered for excellent temperature stability and uniformity throughout the chamber. This ensures that the entire workpiece, regardless of its size or position, experiences the exact same thermal cycle.

This uniformity is critical for achieving consistent grain structure, hardness, and ductility across the material. It eliminates hot or cold spots that can lead to inconsistent results or defects.

Mastering the Protective Atmosphere

The defining feature is its atmosphere control system, typically comprising a gas source, flow meters, and regulating valves. This system allows you to replace the ambient air with a specific gas mixture (e.g., nitrogen, argon).

By precisely controlling the furnace's internal atmosphere, you can prevent oxidation, decarburization, and other unwanted surface reactions. This is essential for processing sensitive materials like titanium alloys and stainless steel, or for applications where a clean, bright finish is required.

Efficiency in Operations and Energy

Beyond process control, these furnaces are designed for practical, real-world production environments where time and cost are critical factors.

Reducing Annealing Cycle Times

Compared to traditional furnace designs, modern box-type units often feature superior insulation and high-efficiency heating elements. This allows for faster heat-up and cool-down rates.

This capability can shorten annealing cycle times by 30% to 50%, directly increasing throughput and productivity without compromising the quality of the heat treatment.

Lowering Energy Consumption

Efficient insulation does more than just speed up heating; it also retains heat effectively. Paired with precise temperature control that prevents energy-wasting temperature overshoots, these furnaces consume significantly less energy per cycle.

Simplifying Operation and Maintenance

Modern furnaces feature user-friendly digital interfaces that make it easy to set, monitor, and record process parameters. This reduces the chance of operator error and simplifies process validation.

Furthermore, many are built with a modular design. This allows for quick disassembly, replacement, and maintenance of key components like heating elements, minimizing downtime and improving overall equipment reliability.

Understanding the Safety and Reliability Features

Operating equipment at high temperatures with controlled atmospheres carries inherent risks. A key advantage of these furnaces is their integrated, multi-layered safety systems.

Built-in Electrical and Thermal Protection

These units are equipped with multiple automatic safety devices. Protections for overcurrent, overvoltage, overheating, and electrical leakage constantly monitor the system.

If an abnormality is detected, the system can instantly cut power and trigger an alarm, protecting both the operator and the equipment from damage.

Preventing Atmosphere Leakage

The furnace door is a critical component, engineered with a reliable sealing structure. This seal serves two purposes: it prevents the controlled atmosphere from leaking out (a safety and cost issue) and stops outside air from leaking in (a process quality issue).

Key Applications and Use Cases

The versatility and precision of the box-type atmosphere furnace make it suitable for a wide range of applications across different industries.

High-Performance Metals Processing

It is widely used for the annealing, stress relieving, or brazing of metals where surface chemistry is critical. Key materials include steel, aluminum alloys, copper alloys, stainless steel, and titanium alloys.

Advanced Materials and Manufacturing

The furnace's precise control is also ideal for processes in the ceramic and glass industries. Furthermore, it is a valuable tool in laboratories for the research and preparation of new materials, such as nanomaterials and composites.

Making the Right Choice for Your Goal

To determine if this furnace is right for you, consider your primary objective.

- If your primary focus is process repeatability and quality: The precise atmosphere and temperature control are your most critical advantages, ensuring consistent material properties batch after batch.

- If your primary focus is operational throughput and cost: The faster heating cycles and lower energy consumption directly translate to higher productivity and reduced operational expenses.

- If your primary focus is safety and ease of use: The comprehensive safety interlocks and intuitive user interface reduce operational risk and minimize the need for specialized operator training.

Ultimately, a box-type annealing atmosphere furnace gives you the control necessary to consistently and efficiently achieve your desired material outcomes.

Summary Table:

| Advantage Category | Key Benefits |

|---|---|

| Process Control | Precise temperature uniformity, accurate atmosphere management, consistent material properties |

| Efficiency | Faster heating/cooling cycles, reduced energy consumption, higher throughput |

| Safety | Built-in electrical and thermal protection, reliable atmosphere sealing |

| Applications | Metals processing, ceramics, glass, nanomaterials, composites |

Ready to enhance your lab's capabilities with a custom box-type annealing atmosphere furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how we can help you achieve superior process control, efficiency, and safety!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process