For any steel application where surface finish and integrity are critical, inert atmosphere heat treating is not just beneficial—it's essential. The process protects steel from high-temperature oxidation and scaling by replacing reactive oxygen with a non-reactive gas like nitrogen. This ensures the final part meets its design specifications for finish, dimensions, and mechanical properties without requiring costly rework.

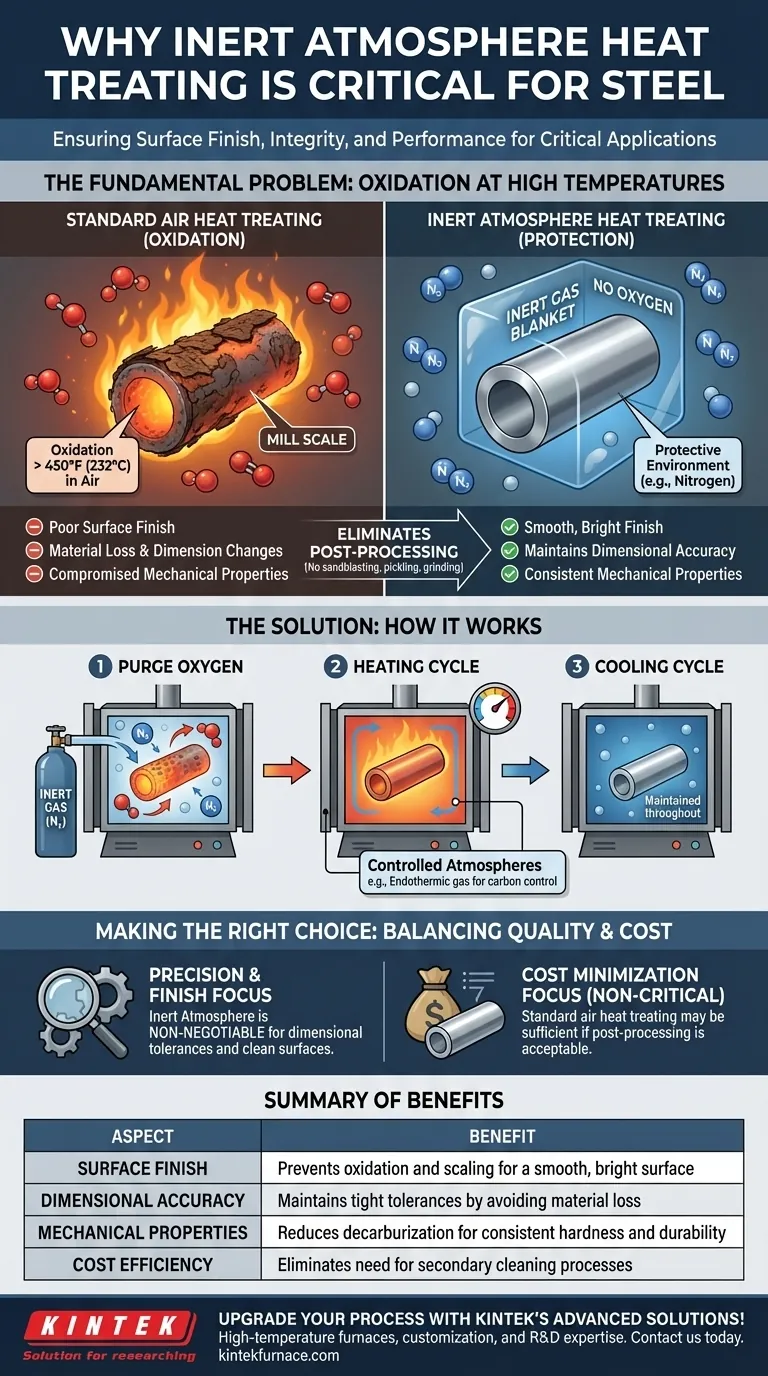

Heat treating steel in standard air causes oxidation, forming a rough, brittle scale that compromises surface finish, dimensional accuracy, and mechanical properties. Inert atmosphere treating solves this by creating a protective environment, preserving the steel's intended quality from the furnace to the final assembly.

The Fundamental Problem: Oxidation at High Temperatures

What is Oxidation and Scaling?

When steel is heated above approximately 450°F (232°C) in the presence of oxygen, a chemical reaction occurs. This reaction, known as oxidation, forms a layer of iron oxides on the surface of the part.

This layer is commonly referred to as mill scale. It is typically dark, flaky, and brittle, adhering poorly to the underlying steel.

The Consequences of Scale Formation

Scale formation is not merely a cosmetic issue. It directly degrades the quality of the component in several ways.

First, it creates a poor surface finish, which is unacceptable for parts requiring a smooth or polished appearance. Second, because scale is formed from the steel itself, its formation results in material loss and changes the part's final dimensions, compromising tight tolerances.

Finally, the uneven, flaky layer can hide surface defects and negatively impact the mechanical properties of the steel's surface.

The Need for Post-Processing

To remove scale, parts heat-treated in air must undergo secondary cleaning operations. These processes, such as sandblasting, chemical pickling, or grinding, add significant time, cost, and complexity to the manufacturing workflow.

How Inert Atmosphere Treatment Solves the Problem

The Core Principle: Removing Oxygen

Inert atmosphere heat treating works by directly addressing the root cause of oxidation: the presence of oxygen. The process takes place inside a sealed furnace or oven.

Before heating, the oxygen-rich air is purged and replaced with a high-purity, non-reactive (inert) gas, most commonly nitrogen. This creates a protective blanket around the part.

The Step-by-Step Process

The procedure is straightforward but requires precise control. First, the furnace chamber is purged with the inert gas until oxygen levels are reduced to a negligible minimum.

The heating cycle then begins, bringing the part to the required temperature for the specified time. This protective atmosphere is maintained throughout the heating and cooling cycles to prevent any oxygen from re-entering and reacting with the hot steel.

Not Just "Inert": Understanding Controlled Atmospheres

While a truly inert gas like nitrogen or argon is used for protection, it's important to recognize other types of "controlled" atmospheres.

For example, an endothermic gas mixture (containing hydrogen, carbon monoxide, and nitrogen) is also used. This type of atmosphere is not strictly inert; the carbon monoxide and hydrogen are reactive. It not only prevents oxidation but can also be precisely controlled to prevent the loss of carbon from the steel's surface (decarburization) or even add carbon to it (carburizing).

Understanding the Trade-offs

Increased Cost and Complexity

The primary trade-off is cost. Inert atmosphere furnaces are more complex and expensive to build and operate than standard air furnaces. The ongoing cost of purchasing high-purity inert gas also adds to the operational expense.

Gas Purity is Critical

The effectiveness of the process hinges entirely on the purity of the inert atmosphere. A leaky furnace seal or a contaminated gas supply can allow trace amounts of oxygen to enter, leading to discoloration or light oxidation, defeating the purpose of the process.

Not Always Necessary

For large, non-critical structural components where surface finish is irrelevant and slight dimensional changes are acceptable, a standard heat treatment in air may be a more cost-effective solution.

Making the Right Choice for Your Steel

Choosing the correct thermal process requires balancing the desired quality against the cost.

- If your primary focus is precision and finish: Inert atmosphere treatment is non-negotiable to maintain dimensional tolerances and deliver a clean, bright surface ready for use.

- If your primary focus is mechanical performance: The process is critical for preventing surface decarburization, which ensures consistent hardness, wear resistance, and fatigue life.

- If your primary focus is minimizing cost on non-critical parts: A standard heat treatment in air may be sufficient if you can accommodate post-processing and slight dimensional changes.

Ultimately, selecting the appropriate heat treatment process is a critical engineering decision that directly impacts the final quality, performance, and cost of your component.

Summary Table:

| Aspect | Benefit |

|---|---|

| Surface Finish | Prevents oxidation and scaling for a smooth, bright surface |

| Dimensional Accuracy | Maintains tight tolerances by avoiding material loss |

| Mechanical Properties | Reduces decarburization for consistent hardness and durability |

| Cost Efficiency | Eliminates need for secondary cleaning processes like sandblasting |

Upgrade your steel heat treating process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs. Contact us today to enhance quality and efficiency in your operations!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More