At its core, a controlled atmosphere furnace is used whenever the chemical integrity of a material must be protected or precisely altered during a high-temperature process. They are fixtures in industrial manufacturing for processes like brazing, annealing, and semiconductor sintering, as well as in academic research for developing new materials. The common thread is the need to eliminate or strictly regulate reactive gases, primarily oxygen, that would otherwise compromise the final product.

The fundamental value of a controlled atmosphere furnace isn't just heating; it's creating a chemically perfect environment at high temperatures. This prevents destructive oxidation and allows for the fabrication of materials with the exact properties required for high-performance applications.

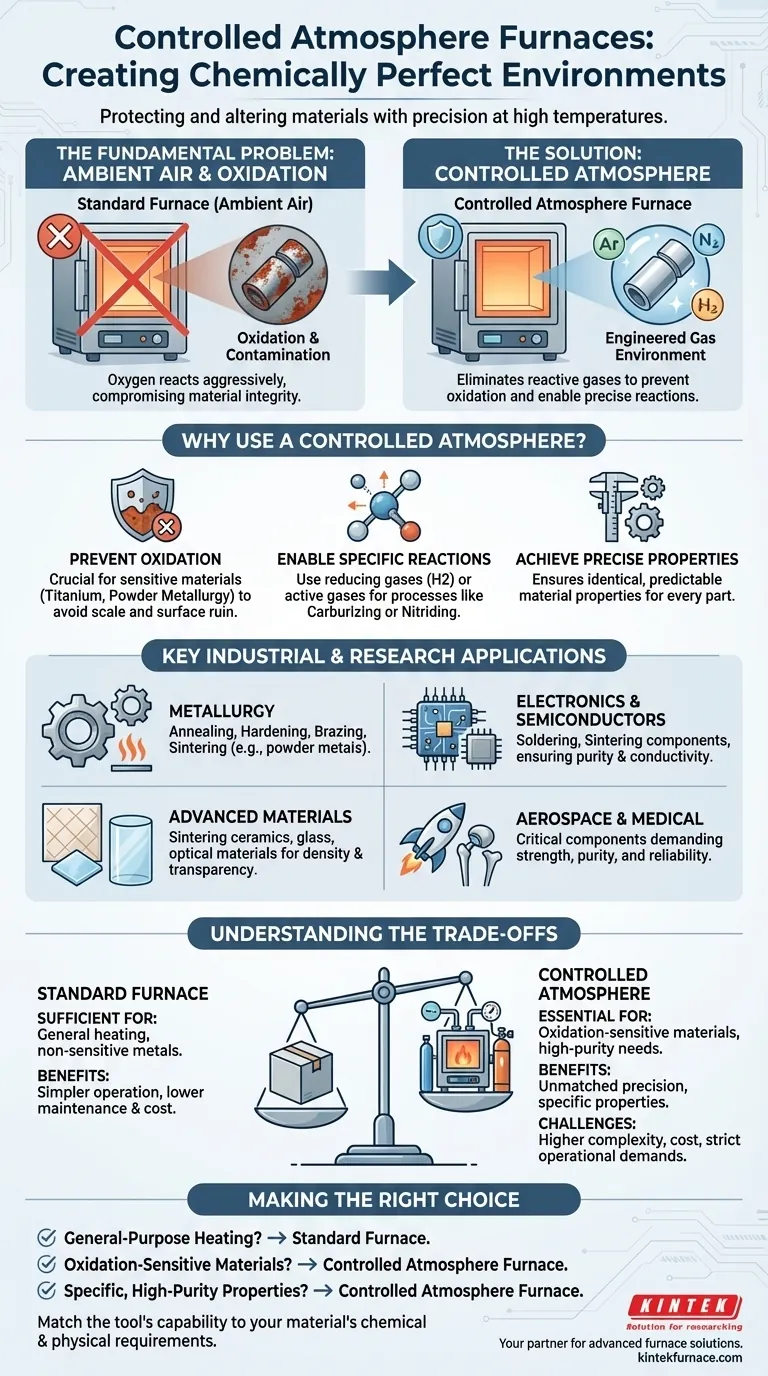

The Fundamental Problem: Why Control the Atmosphere?

Standard furnaces heat materials in ambient air, which is rich in oxygen. At high temperatures, this oxygen aggressively reacts with most materials, causing undesirable changes. A controlled atmosphere furnace solves this by replacing the air with a specific, engineered gas environment.

Preventing Oxidation and Contamination

The most common reason to use a controlled atmosphere is to prevent oxidation. For metals, this means preventing the formation of scale or rust, which weakens the material and ruins its surface finish.

This is critical for oxidation-sensitive materials like titanium alloys or for processes like powder metallurgy, where a pure, unoxidized result is essential.

Enabling Specific Chemical Reactions

Beyond simply being protective, the atmosphere can be an active ingredient in the process. A furnace can be filled with a reducing gas (like hydrogen) to actively strip oxygen atoms from a material's surface.

Conversely, a carefully controlled amount of a specific gas can be introduced to create a desired surface layer, a process known as carburizing or nitriding in steel treatment.

Achieving Precise, Repeatable Material Properties

By eliminating the random variable of ambient air, these furnaces provide absolute control. This ensures that every part processed—whether for an aerospace engine or a medical implant—has identical, predictable, and reliable material properties.

Key Industrial and Research Applications

The need for this level of control makes these furnaces indispensable across a range of advanced fields.

Metallurgy and Metal Processing

In metallurgy, atmosphere furnaces are used for annealing (softening metal), hardening, and brazing (joining metals). These processes require clean, oxide-free surfaces to be successful. They are also essential for sintering pressed metal powders into solid, dense components.

Electronics and Semiconductor Manufacturing

The electronics industry relies heavily on controlled atmospheres. Processes like soldering circuit boards and sintering semiconductor components demand extreme purity to ensure proper electrical conductivity and prevent defects.

Advanced Materials and Ceramics

Manufacturing advanced ceramics, glass, and optical materials often involves sintering at very high temperatures. A controlled atmosphere ensures the final product has the desired density, transparency, and chemical composition without being compromised by unwanted reactions.

High-Stakes Industries: Aerospace and Medical

Industries where failure is not an option, such as aerospace and medical device manufacturing, depend on the precision of atmosphere furnaces. They guarantee that critical components meet stringent specifications for strength, purity, and longevity.

Understanding the Trade-offs

While powerful, a controlled atmosphere furnace is a specialized tool that isn't always necessary. Its benefits come with increased complexity and cost.

When a Standard Furnace Is Sufficient

For basic scenarios like general-purpose heat treatment of non-sensitive metals, simple ceramic firing, or lab sample heating, a conventional box furnace is often sufficient. These units are simpler to operate and have lower maintenance costs.

The Cost of Precision

A controlled atmosphere system is inherently more complex. It requires gas storage, high-purity plumbing, circulation systems, and sophisticated sensors to maintain the environment. This increases the initial investment and operational overhead.

Critical Operational Demands

Operating these furnaces requires strict discipline. Key factors include maintaining precise gas composition, using high-purity gases, continuous monitoring of temperature and pressure, and following rigorous safety protocols to manage potentially flammable or inert gases.

Making the Right Choice for Your Goal

Selecting the correct heating technology depends entirely on the required outcome for your material.

- If your primary focus is general-purpose heating or processing non-reactive materials: A standard furnace is likely the most cost-effective and practical choice.

- If your primary focus is processing oxidation-sensitive materials like titanium or copper: A controlled atmosphere furnace is essential to protect material integrity.

- If your primary focus is achieving specific, high-purity material properties for electronics or medical devices: The precise environmental control of an atmosphere furnace is non-negotiable.

Ultimately, choosing the right furnace is about matching the tool's capability to the material's specific chemical and physical requirements.

Summary Table:

| Application Area | Key Uses | Key Benefits |

|---|---|---|

| Metallurgy | Annealing, brazing, sintering | Prevents oxidation, enables precise material properties |

| Electronics | Soldering, semiconductor sintering | Ensures purity, prevents defects |

| Aerospace & Medical | Component manufacturing | Guarantees strength, purity, and reliability |

| Advanced Materials | Ceramics and glass sintering | Achieves desired density and composition |

Need a high-temperature furnace tailored to your unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your experimental requirements, enhancing efficiency and reliability in your lab. Contact us today to discuss how we can support your high-stakes applications!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.