At its core, an inert oven provides one critical advantage: complete control over the chemical environment during heating. By replacing reactive gases like oxygen with a non-reactive (inert) gas such as nitrogen or argon, it prevents unwanted chemical reactions, primarily oxidation. This allows for the safe and effective thermal processing of sensitive materials that would otherwise degrade, contaminate, or fail in a standard, air-filled oven.

The fundamental difference is control. A standard oven only controls temperature, leaving the material exposed to reactive air. An inert oven controls both temperature and the chemical atmosphere, eliminating oxidation as a variable and ensuring the material's intrinsic properties are preserved.

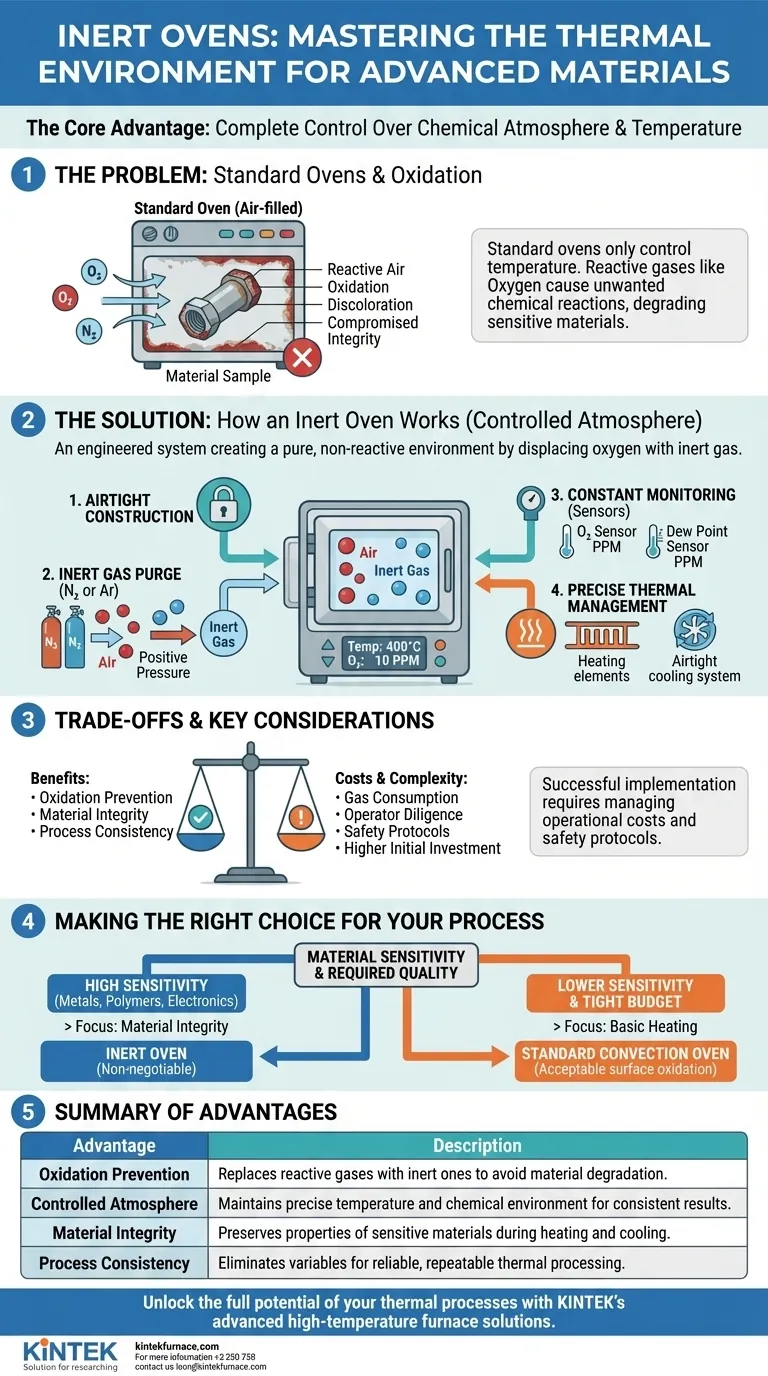

Why a Standard Oven Fails: The Problem of Oxidation

The Inescapable Reactivity of Air

Air, which is approximately 21% oxygen, is highly reactive, especially at elevated temperatures. When you heat a material in a conventional oven, you are not just heating the material; you are actively promoting chemical reactions on its surface.

The Consequences of Unwanted Reactions

For many advanced materials, this reaction is a critical failure point. Oxidation can lead to discoloration, compromised structural integrity, altered electrical properties, and a complete loss of desired performance. This makes standard ovens unsuitable for processes like curing sensitive polymers, annealing certain metals, or processing electronic components.

The Core Mechanism: How an Inert Oven Creates a Controlled Atmosphere

An inert oven is not simply a sealed box; it is an engineered system designed to create and maintain a pure, non-reactive environment. This is achieved through several key features working in concert.

Airtight Construction: The First Line of Defense

The foundation of any inert oven is a hermetically sealed chamber. This typically involves fully welded interior shells and specially designed door gaskets to prevent any ambient air from leaking into the controlled environment.

Gas Purging: Replacing Reactive Air

Before and during the heating process, an inert gas (most commonly nitrogen) is flushed through the chamber. This purging process displaces all the oxygen and moisture. A sophisticated gas control system manages the flow rate to maintain a slight positive pressure, ensuring any potential leaks flow outward, not inward.

Constant Monitoring: Ensuring Purity

To guarantee the environment remains inert, advanced ovens incorporate sensors. An oxygen sensor continuously monitors the internal atmosphere, ensuring O₂ levels remain at a parts-per-million (PPM) level. Similarly, a dew point sensor can monitor moisture, which is another source of unwanted reactions.

Precise Thermal Management: From Heating to Cooling

Controlling the atmosphere is useless without precise temperature control. Inert ovens feature advanced temperature controllers for uniform heating. Crucially, many also include airtight cooling systems that allow the material to cool down in the inert atmosphere, preventing oxidation that could occur if it were exposed to air while still hot.

Understanding the Trade-offs and Key Considerations

While invaluable, transitioning to an inert oven involves a clear set of trade-offs that must be managed for a successful process.

Gas Consumption and Cost

The primary operational cost of an inert oven is the inert gas itself. Continuous purging, especially for long cycles or in less-than-perfectly-sealed ovens, can lead to significant nitrogen or argon consumption, which must be factored into the total cost of operation.

Increased Process Complexity

Operating an inert oven requires more diligence than a standard model. Operators must manage gas flow rates, monitor oxygen levels, and follow specific procedures for loading and unloading to avoid contaminating the inert atmosphere.

Safety Protocols

The use of compressed gases like nitrogen introduces new safety considerations. Proper ventilation is essential to prevent asphyxiation risk in the event of a major leak, and operators must be trained in the safe handling of high-pressure gas cylinders.

Higher Initial Investment

Due to their specialized construction, control systems, and sensors, inert ovens represent a significantly higher capital investment compared to standard industrial ovens of a similar size and temperature range.

Making the Right Choice for Your Process

Deciding whether you need an inert oven comes down to the sensitivity of your material and the required quality of your final product.

- If your primary focus is material integrity and preventing any oxidation: An inert oven is non-negotiable for processing sensitive metals, advanced polymers, or electronic components.

- If your primary focus is process consistency and repeatability: The controlled atmosphere of an inert oven eliminates environmental variables, leading to more reliable and predictable outcomes batch after batch.

- If you are working with a tight budget and non-sensitive materials: A standard convection oven may be sufficient if a small amount of surface oxidation is acceptable for your application.

Ultimately, an inert oven empowers you to dictate the precise conditions of your thermal process, ensuring your material's final properties are a result of design, not chance.

Summary Table:

| Advantage | Description |

|---|---|

| Oxidation Prevention | Replaces reactive gases with inert ones to avoid material degradation. |

| Controlled Atmosphere | Maintains precise temperature and chemical environment for consistent results. |

| Material Integrity | Preserves properties of sensitive materials during heating and cooling. |

| Process Consistency | Eliminates variables for reliable, repeatable thermal processing. |

Unlock the full potential of your thermal processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing material integrity and process efficiency. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance