In short, the IGBT transistor heating power supply is the core control system that provides the precise, high-frequency energy required for the induction heating of magnesium. Its primary function is to convert standard electrical power into a finely adjustable output that can rapidly and stably heat the magnesium to its evaporation temperature, directly controlling the quality of the final powder.

The central challenge in producing magnesium powder via induction heating isn't just generating heat, but controlling that heat with absolute precision. The IGBT power supply is the critical component that delivers this control, turning a brute-force heating process into a refined manufacturing tool that dictates product consistency and yield.

The Core Principle: Converting Power into Precision

Induction heating works by using a powerful, alternating magnetic field to induce electrical currents (eddy currents) directly within the magnesium. These currents generate intense heat due to the metal's natural resistance, causing it to evaporate without direct contact from a heat source.

The IGBT's Fundamental Role

The IGBT (Insulated-Gate Bipolar Transistor) power supply is the "engine" that creates this magnetic field. It acts as an incredibly fast and efficient electronic switch.

It takes standard mains electricity and converts it into the high-frequency alternating current needed to power the induction coil.

Why Frequency and Power Matter

The effectiveness of induction heating is determined by the frequency and power of the electrical current. The IGBT power supply gives operators exact control over both of these variables.

This allows for the precise management of the heating rate and the final temperature of the magnesium.

The Direct Impact on Magnesium Powder Quality

The precise energy control provided by the IGBT power supply is not just an operational convenience; it is a fundamental requirement for producing high-quality magnesium powder consistently.

Achieving a Constant Evaporation Rate

For magnesium powder to have uniform characteristics, the metal must evaporate at a steady, predictable rate.

The IGBT supply ensures a stable power output, which maintains a constant temperature in the magnesium crucible. This stability is crucial for a smooth and consistent evaporation process.

Controlling Final Powder Characteristics

The rate of evaporation directly influences the final properties of the condensed magnesium powder, such as its particle size and overall yield.

By precisely controlling the energy input, manufacturers can ensure the powder produced meets strict specifications for consistency and quality across different production runs.

Ensuring Batch-to-Batch Repeatability

Because the power and frequency settings of an IGBT supply are digitally controlled, the exact same heating profile can be replicated perfectly time and time again.

This high degree of repeatability is essential for industrial-scale manufacturing, guaranteeing that every batch of powder is identical.

Why IGBT Technology is the Standard

While other methods can generate heat, IGBT-based induction power supplies offer a combination of benefits that make them the superior choice for demanding applications like this.

Unmatched Energy Efficiency

IGBTs are solid-state semiconductor devices that convert electricity with very little loss. This high efficiency translates directly into lower energy consumption and reduced operational costs compared to older technologies.

Superior Controllability

The ability to adjust power and frequency in real-time gives operators unparalleled control over the heating process. This is something older vacuum tube or motor-generator systems could not achieve with the same precision or speed.

High Reliability and Compact Design

As solid-state electronics with no moving parts, IGBT power supplies are exceptionally reliable and require minimal maintenance. They are also significantly more compact than their predecessors, saving valuable floor space.

How to Apply This to Your Process

The choice and use of the power supply directly link to your manufacturing goals.

- If your primary focus is product quality: The IGBT power supply's precise control over heating stability is the most critical factor for determining final powder particle size and consistency.

- If your primary focus is process efficiency: This technology ensures the fastest possible heating cycles and the highest energy conversion rate, which minimizes production time and cost.

- If your primary focus is operational repeatability: The digital and solid-state nature of the IGBT system guarantees that your heating parameters can be perfectly replicated for every single batch.

Ultimately, the IGBT power supply transforms induction heating from a simple heat source into a precision manufacturing instrument.

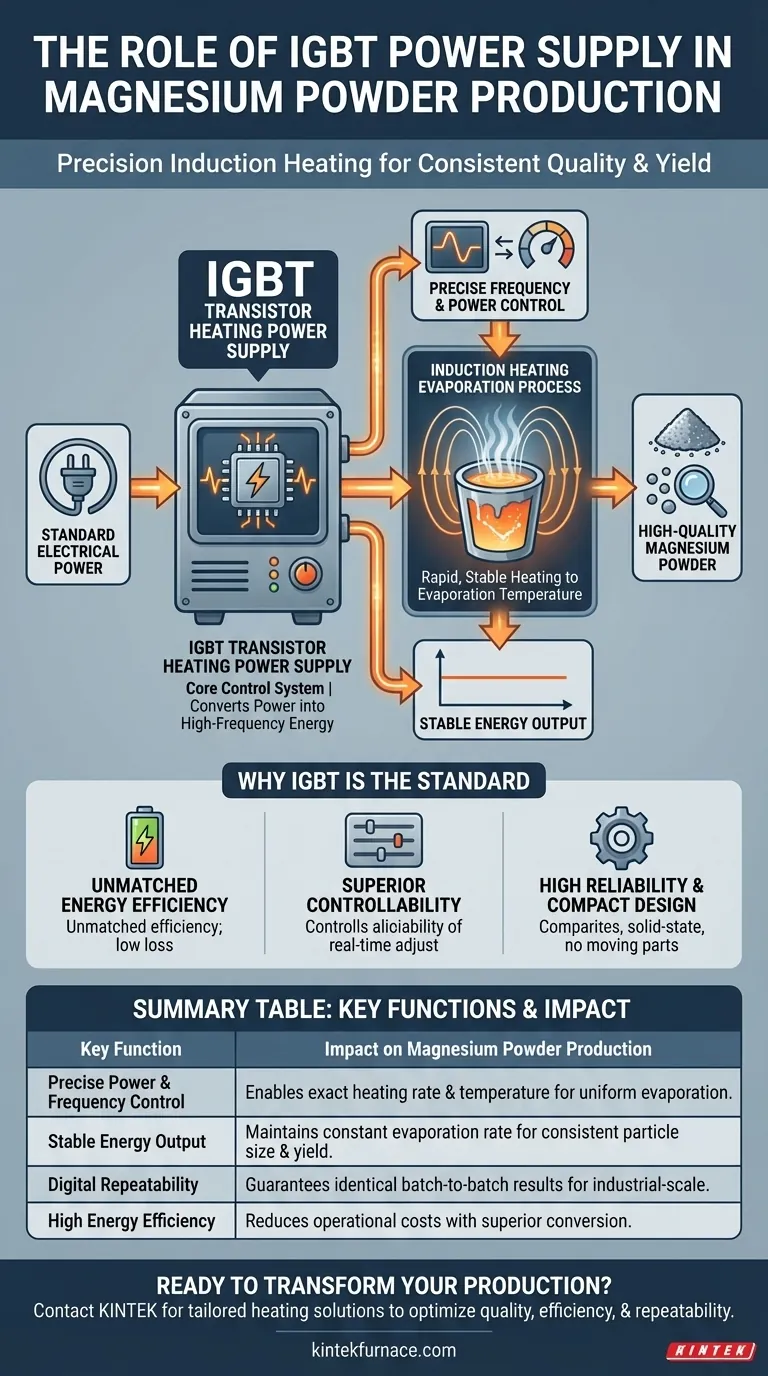

Summary Table:

| Key Function | Impact on Magnesium Powder Production |

|---|---|

| Precise Power & Frequency Control | Enables exact heating rate and temperature management for uniform evaporation. |

| Stable Energy Output | Maintains a constant evaporation rate for consistent particle size and yield. |

| Digital Repeatability | Guarantees identical batch-to-batch results for industrial-scale manufacturing. |

| High Energy Efficiency | Reduces operational costs with superior electrical conversion and minimal loss. |

Ready to transform your magnesium powder production with precision heating?

The precise control of an IGBT power supply is critical for achieving high-quality, consistent results. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs like your induction heating process.

Contact our experts today to discuss how a tailored heating solution can optimize your powder quality, efficiency, and repeatability.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance