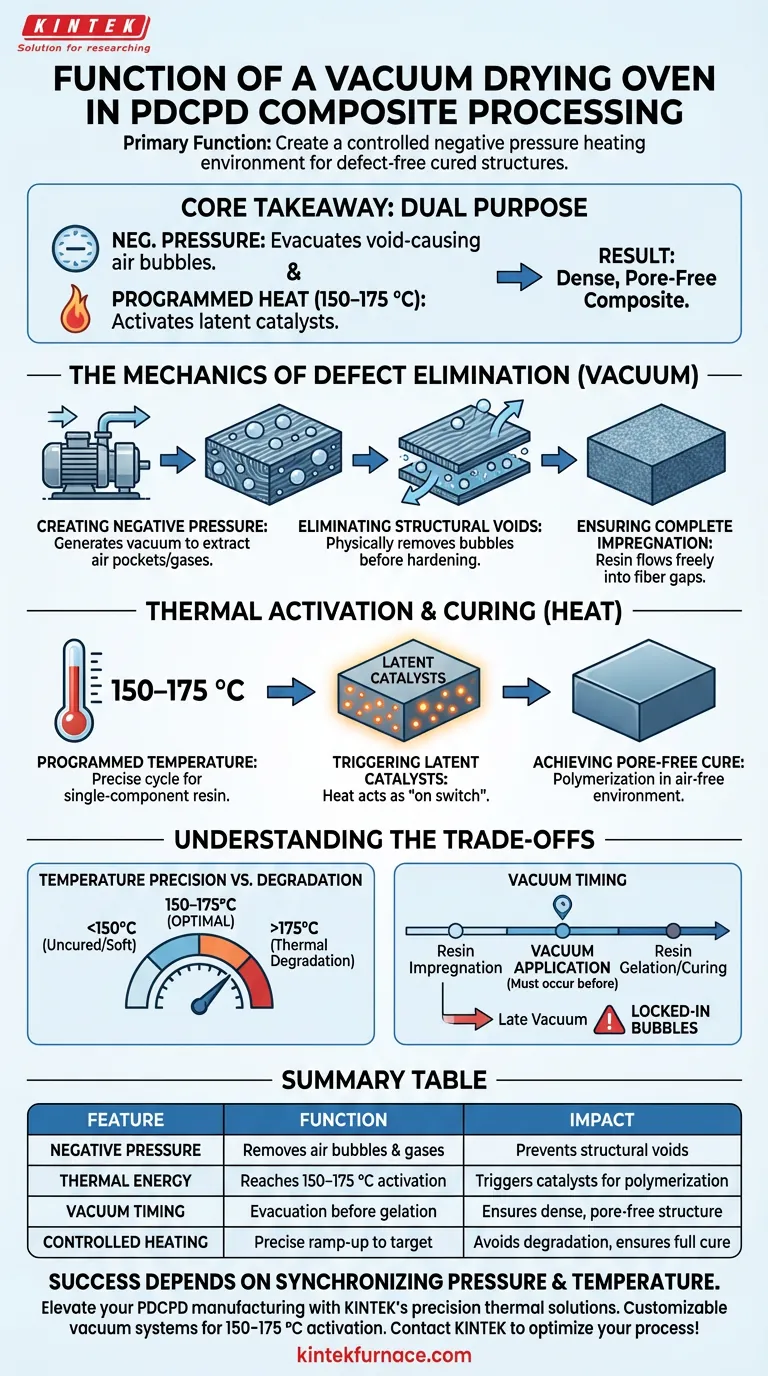

The primary function of a vacuum drying oven in processing poly(dicyclopentadiene) (PDCPD) composites is to create a controlled negative pressure heating environment that ensures a defect-free cured structure. Specifically, it eliminates air bubbles trapped during resin impregnation while simultaneously providing the thermal energy required to activate the resin's catalyst system.

Core Takeaway The vacuum drying oven serves a dual purpose: it utilizes negative pressure to evacuate void-causing air bubbles and applies programmed heat (typically 150–175 °C) to activate latent catalysts. This combination ensures the resin fully penetrates fiber gaps, resulting in a dense, pore-free composite.

The Mechanics of Defect Elimination

Creating a Negative Pressure Environment

The oven operates by generating a negative pressure atmosphere around the composite material.

This vacuum condition is essential for extracting air pockets and volatile gases that become trapped within the matrix during the resin impregnation process.

Eliminating Structural Voids

If these air bubbles are not removed, they result in voids within the final material.

By physically pulling these bubbles out of the resin before it hardens, the oven prevents the formation of structural weaknesses that would compromise the composite's integrity.

Ensuring Complete Impregnation

The removal of air creates space for the dicyclopentadiene monomer to flow freely.

This allows the resin to fully permeate the gaps between fibers, ensuring a consistent and solid internal structure.

Thermal Activation and Curing

Programmed Temperature Increases

The process relies on a precise thermal cycle, typically ranging from 150 °C to 175 °C.

This temperature range is not arbitrary; it is specifically calibrated to the chemistry of the single-component resin system used in these composites.

Triggering Latent Catalysts

The heat supplied by the oven serves as the "on switch" for latent catalysts mixed within the resin.

These catalysts remain inactive at lower temperatures, preventing premature curing and allowing time for the vacuum to do its work.

Achieving a Pore-Free Cure

Once activated by the heat, the catalyst initiates the polymerization of the dicyclopentadiene.

Because the vacuum has already removed the air, the resin cures into a pore-free structure, locking the dense, impregnated state into place permanently.

Understanding the Trade-offs

Temperature Precision vs. Degradation

While heat is necessary for activation, strict adherence to the 150 °C to 175 °C range is critical.

Deviating below this range may fail to activate the catalyst, leading to an uncured, soft part. Exceeding it could risk thermal degradation of the polymer matrix.

Vacuum Timing

The application of vacuum must coincide with the heating ramp before the resin gels.

If the resin cures (hardens) before the vacuum has fully evacuated the air, the bubbles will be locked in permanently, rendering the process ineffective.

Making the Right Choice for Your Goal

To maximize the quality of your poly(dicyclopentadiene) composites, focus on the synchronization of pressure and temperature.

- If your primary focus is structural integrity: Prioritize the vacuum cycle to ensure all air is evacuated before the peak temperature is reached to prevent voids.

- If your primary focus is process efficiency: Optimize the heating ramp rate to reach the activation window (150–175 °C) as quickly as possible without causing thermal shock.

Success depends on balancing negative pressure for void removal with precise heating for catalyst activation.

Summary Table:

| Feature | Function in PDCPD Processing | Impact on Final Material |

|---|---|---|

| Negative Pressure | Removes air bubbles and volatile gases | Prevents structural voids and weaknesses |

| Thermal Energy | Reaches 150–175 °C activation window | Triggers latent catalysts for polymerization |

| Vacuum Timing | Evacuation before resin gelation | Ensures a dense, pore-free internal structure |

| Controlled Heating | Precise ramp-up to target temperature | Avoids thermal degradation and ensures full cure |

Elevate your PDCPD composite manufacturing with KINTEK’s precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, and Vacuum systems designed to meet the rigorous 150–175 °C activation requirements for high-performance resins. Ensure structural integrity and eliminate defects with our industry-leading high-temp lab furnaces. Contact KINTEK today to optimize your curing process!

Visual Guide

References

- Benjamin R. Kordes, Michael R. Buchmeiser. Ring‐Opening Metathesis Polymerization‐Derived Poly(dicyclopentadiene)/Fiber Composites Using Latent Pre‐Catalysts. DOI: 10.1002/mame.202300367

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the characteristics, advantages, and disadvantages of a vacuum sintering furnace? Maximize Material Purity and Performance

- What is the role of a high-temperature vacuum furnace in OLC production? Key to Nanodiamond Transformation

- What was the traditional insulation setup in vacuum furnaces, and how has it changed? Discover the Modern All-Felt System

- What factors influence the design and selection of heating elements in vacuum furnaces? Optimize for Temperature, Purity, and Cost

- What is the function of computer-controlled systems in modern vacuum furnaces? Achieve Unwavering Precision & Repeatability

- Why is a vacuum drying oven necessary for chitosan and iron sludge particles? Expert Structural Preservation Guide

- Why are ZrO₂ ceramic blocks utilized as auxiliary fixtures during the vacuum brazing of TC4 titanium alloys?

- What role do vacuum annealing furnaces play in optical material processing? Enhance Clarity and Performance for Your Optics